Miniature ornithopter with wing twisting function and multiple flight motion functions

A flapping-wing aircraft and motion technology, applied in the field of micro flapping-wing aircraft, can solve the problems of difficult miniaturization and complex design structure, and achieve the effects of improving aerodynamic characteristics, strong practicability, and comprehensive flight actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

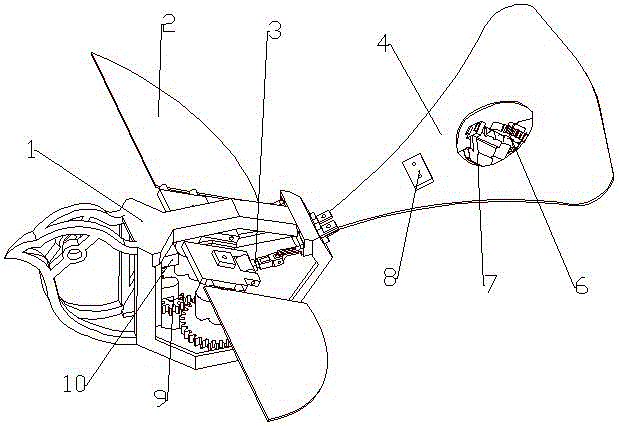

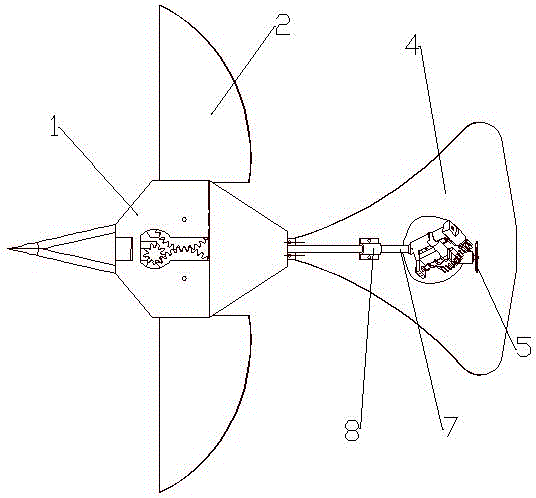

[0021] The flapping torsion mechanism 3, empennage 4, fuselage DC motor 9, empennage support bar 7 and electronic control module 10 are installed on the frame body 1, the wings 2 are connected on the torsion panel 306, and the adjustment steering rotor 5 is connected to the fan motor 608, the empennage transmission mechanism 6 is connected to the empennage support bar 7, and the fixed empennage support bar structure 8 fixes the empennage support bar 7 and the empennage 4 through screws to play a supporting role.

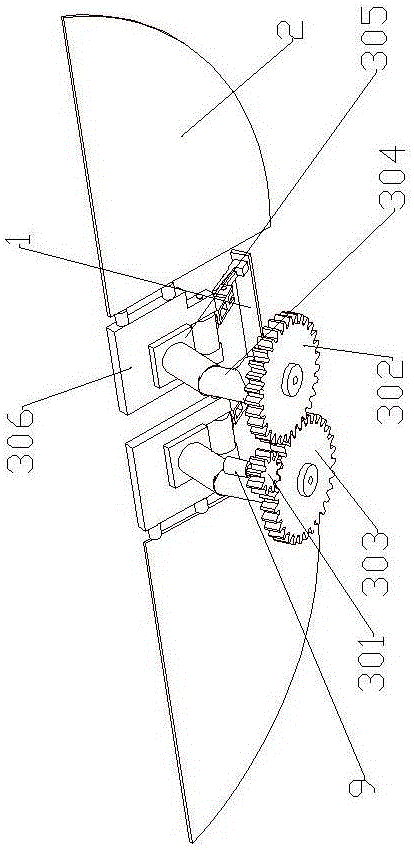

[0022] Described flutter twisting mechanism 3 is made up of right side motion structure and left side motion structure, and both structures are identical, the right gear 302 of right side motion structure and the left gear 303 meshing connection of left side motion structure, pinion one 301 is meshed with the left gear 303, wherein the right side movement structure is: one end of the right gear bending shaft 304 is fixed at the center of the right gear 302, and the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com