Automatic opening binding device

A tying device and automatic technology, applied in the directions of packaging, transportation packaging, transportation and packaging, can solve the problems of time-consuming and laborious, low manual bundling efficiency, unfavorable structure, automatic tying and other problems, and achieve a large amount of aluminum wire. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

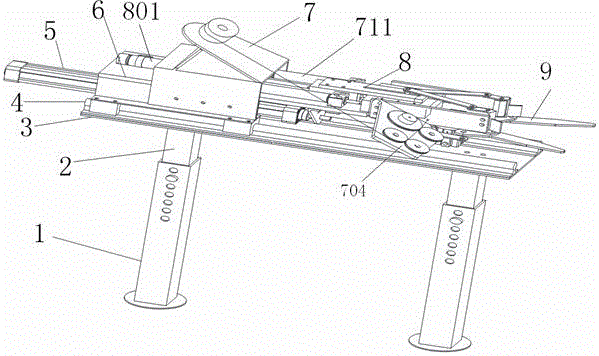

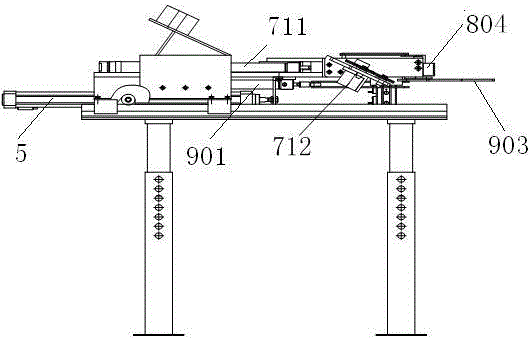

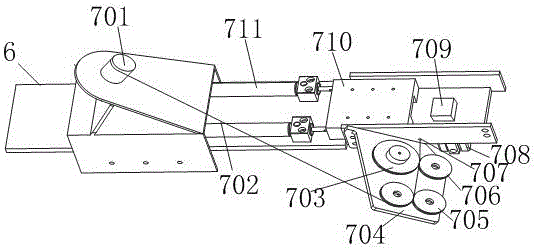

[0018] Refer to the following Figure 1 to Figure 5 , the specific implementation manners of the present invention are given to further illustrate the present invention, but the present invention is not limited to the specific examples described below.

[0019] An automatic binding device, comprising legs, a chassis 3, a guide rail 4, a sliding platform 6, a bag collection mechanism 9 for closing the bag mouth, a wire feeding mechanism, a nail making mechanism 7 for cutting and bending the silk thread, and The finished nails are pushed to the binding position and the binding mechanism 8 for binding; the bag collecting mechanism 9 , wire feeding mechanism, nail making mechanism 7 and binding mechanism 8 are all arranged on the sliding platform 6 .

[0020] The outriggers are divided into upper outrigger 2 and lower outrigger 1. The upper outrigger 2 is installed inside the lower outrigger 1. The chassis 3 is fixed on the upper end of the upper outrigger 2. The upper outrigger 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com