A forklift that can move in all directions

An omnidirectional mobile and forklift technology, applied in the direction of the lifting device, can solve the problems of low height, unsuitable automatic transfer of goods, and automatic adjustment of the distance between the forks, etc., to achieve the effect of easy fork picking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail.

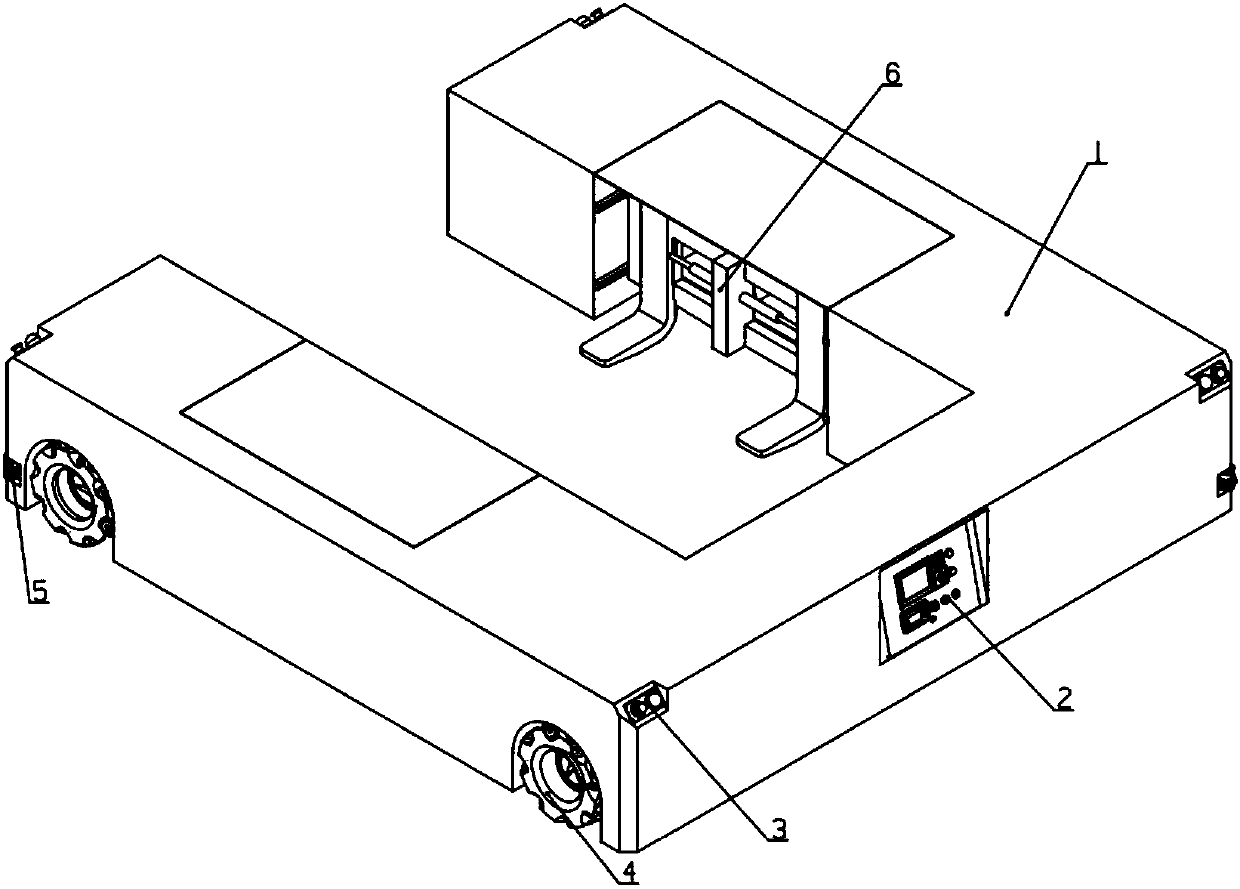

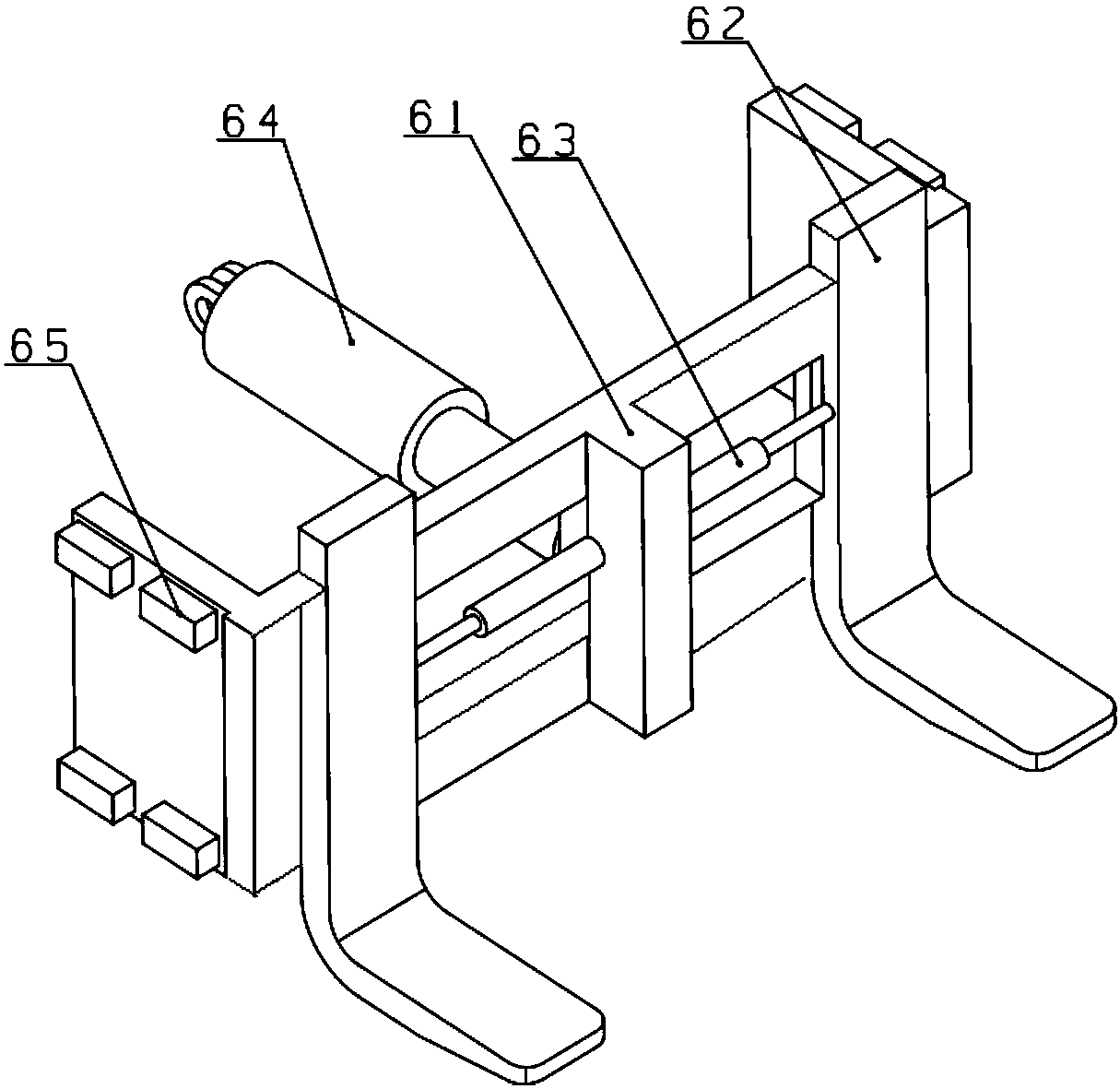

[0010] Such as figure 1 As shown, the present invention provides a forklift that can move in all directions, including a car body 1, an integrated control box 2, an acousto-optic alarm module 3, a wheel 4, a laser scanner 5 and a fork module 6; Outriggers and a beam form a "U"-shaped structure, and the whole forklift is controlled by a remote control; the wheels use mecanum wheels, and the omnidirectional movement of the forklift can be realized by controlling the four mecanum wheels; the mecanum wheels and the car body There is a hydraulic balance suspension between them, which can realize the adaptation of the forklift to the uneven ground. At the same time, the suspension also has a certain lifting capacity to realize the overall lifting of the forklift; the integrated control box 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com