Fracturing devices used in tubing strings

A technology of fracturing and pipe strings, which is applied in the direction of wellbore/well valve devices, wellbore/well components, production fluids, etc., and can solve problems such as unfavorable oil production, water outflow from reservoirs, and failure of normal production of wells, etc., to achieve Simple structure, easy assembly, and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

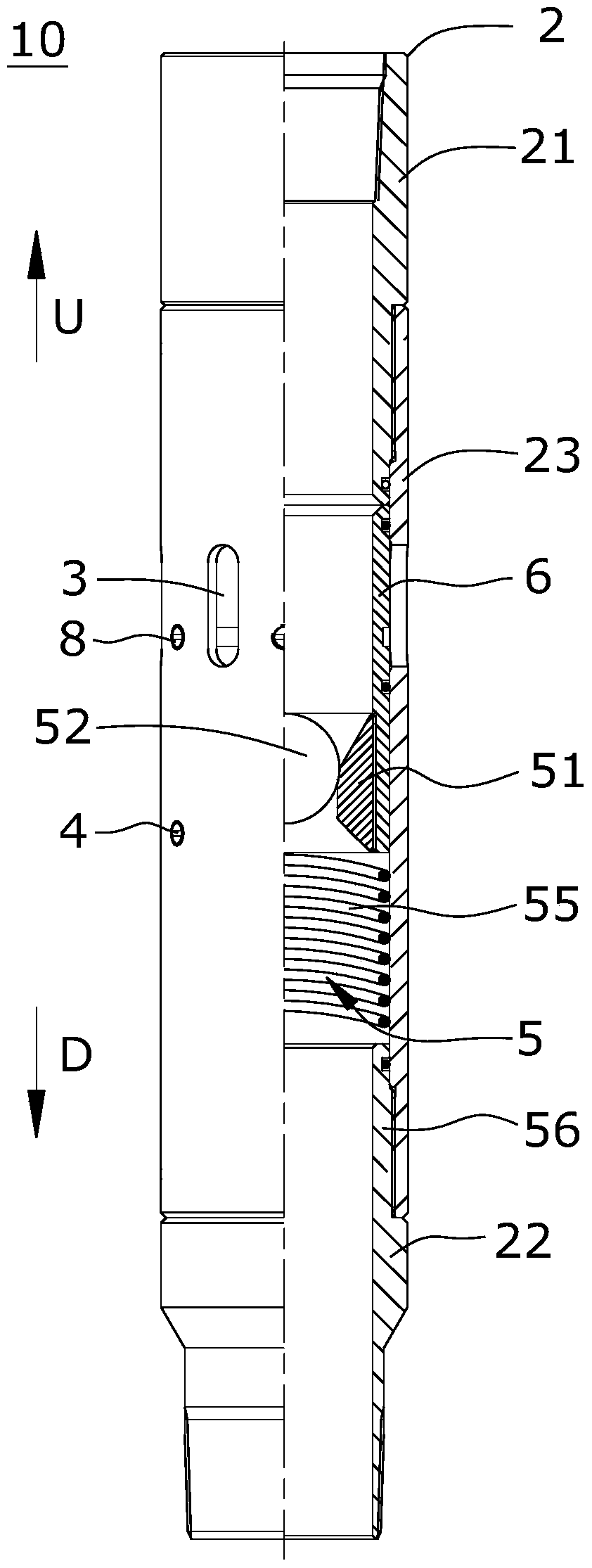

[0026] figure 1 A fracturing device 10 for use in a pipe string according to the invention is shown. The fracturing device 10 includes a tubular body 2 connected in a tubular string (not shown). Considering the convenience of assembly, the pipe body 2 can be configured in a split structure, for example, the pipe body 2 includes an upper joint 21 and a lower joint 22 for connecting with the pipe column, and a middle part 23 for connecting the upper joint 21 and the lower joint 22 . Between each joint and the middle part 23, and between each joint and the pipe string, threaded connections, especially conical threaded connections, can be used. In addition, the pipe body 2 may also adopt a one-piece structure. Wherein, the column is well known to those skilled in the art, and will not be described in detail here.

[0027] A fracturing opening 3 and a guide member 4 are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com