Oil duct damping and noise reducing structure provided with built-in filter

A filter and oil channel technology, applied in the field of oil channel shock absorption and noise reduction structure, can solve problems such as oil channel vibration and noise, and achieve the effects of reducing the requirements for machining dimensional accuracy, improving fault tolerance, and preventing axial movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

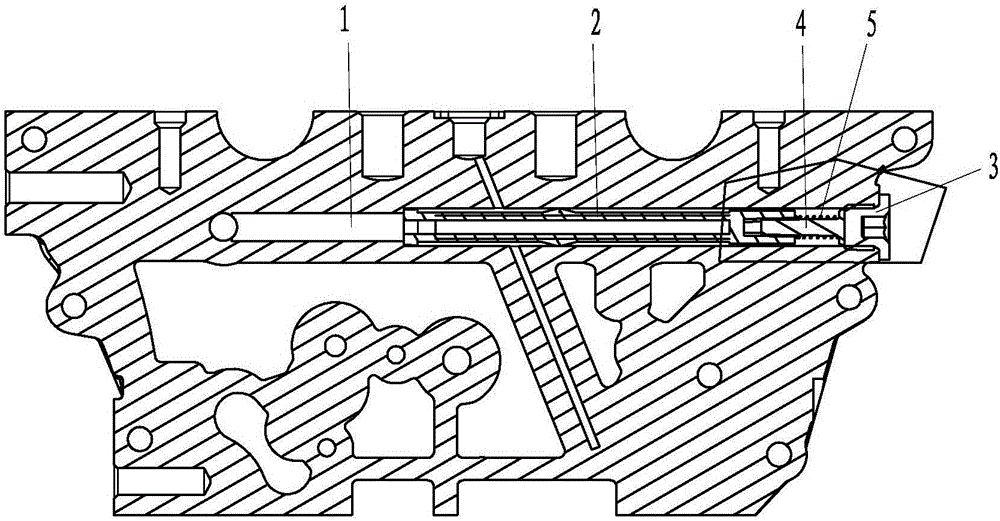

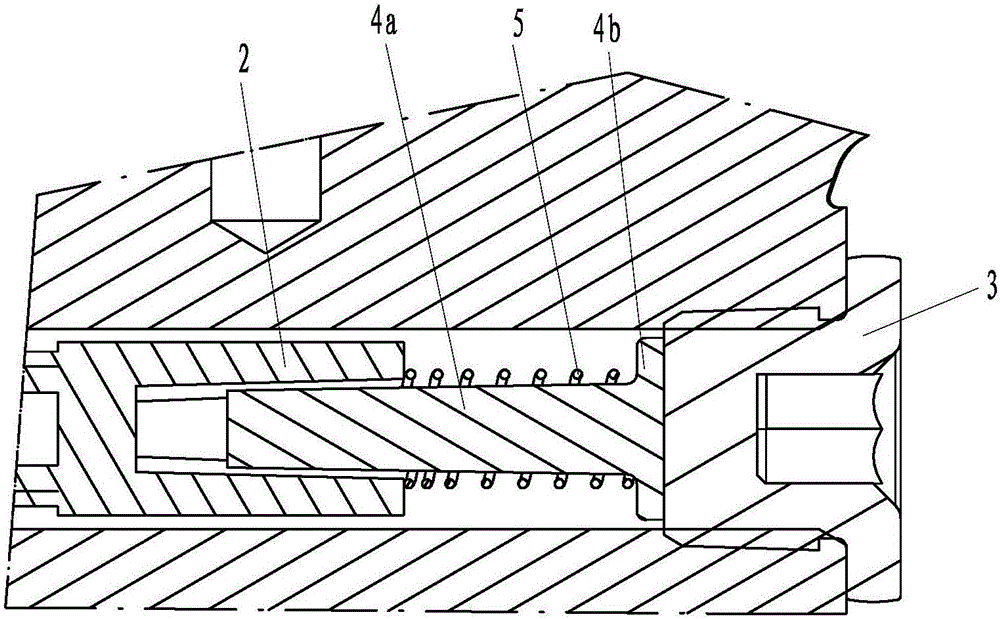

[0010] to combine figure 1 — figure 2 As shown, an oil passage with a built-in filter for shock absorption and noise reduction is mainly composed of an oil passage 1, a filter 2, a threaded plug 3, a guide rod 4 and a cylindrical coil spring 5.

[0011] The filter 2 is placed in the oil passage 1, and the front end of the filter 2 is limited by the stepped surface in the oil passage 1. The threaded plug 3 is installed at the end of the oil passage 1, and the end of the oil passage 1 is provided with an internal thread matching the threaded plug 3.

[0012] A guide rod 4 and a cylindrical coil spring 5 are installed between the filter 2 and the threaded plug 3 . The guide rod 4 is divided into a guide rod part 4a and an end part 4b, and the diameter of the guide rod part 4a is smaller than that of the end part 4b. The tail end of the filter 2 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com