Gear and spindle transmission structure with clutch

A technology of main shaft drive and clutch gear, applied in the direction of gear transmission, belt/chain/gear, transmission, etc., can solve the problems such as the inability to provide power for the tool change gear pair and the absence of the main shaft box, achieving low cost and convenient production. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

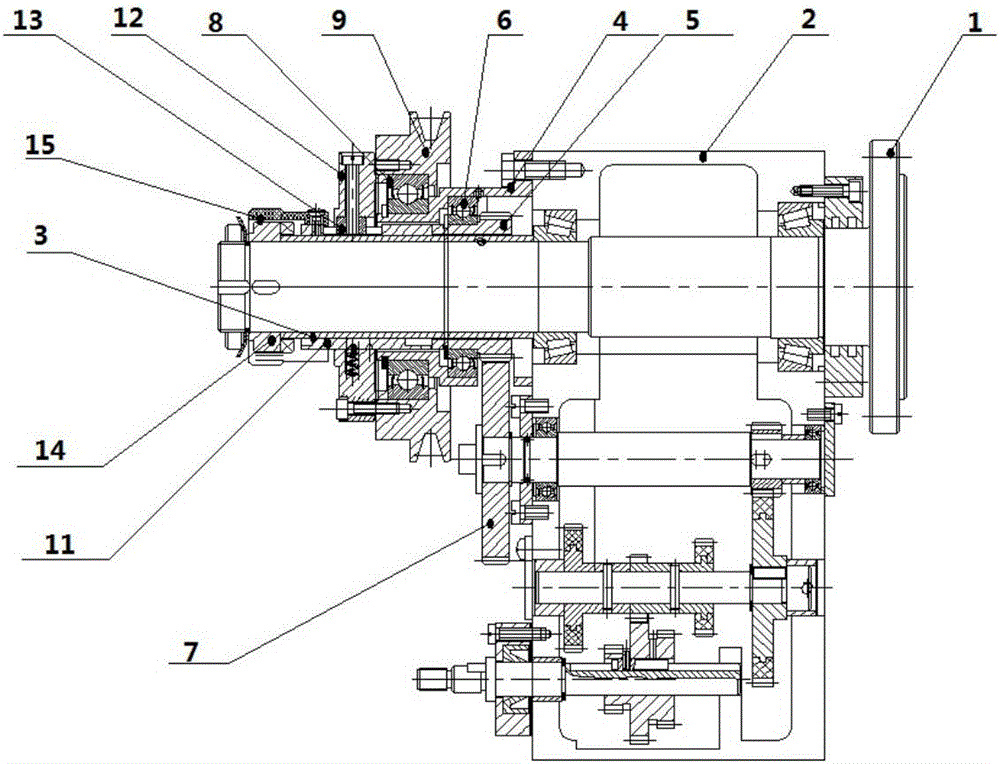

[0013] A gear and main shaft transmission structure with a clutch, such as figure 1 As shown, it includes the main shaft 1 and the box body 2, the left end of the main shaft 1 passes through the box body 2, the part of the main shaft 1 passing through the box body 2 is covered with a long spacer 3, and the bearing seat 4 is set on the long spacer 3 and the bottom of the bearing seat 4 is fixed on the left side of the box body 2 through a bolt structure, and the clutch gear 5 is fixed in the bearing seat 4 through the first bearing 6 and the retaining ring for the shaft. The input gear 7 on the box body 2 is meshed, and the bearing seat 4 at the connection between the clutch gear 5 and the input gear 7 is provided with an opening, and the first bearing 6 is fixed on the inner wall of the bearing seat 2 by tightening screws. , the second bearing 8 is set on the bearing seat 4 through the shaft retaining ring, the pulley 9 is set on the bearing seat 4 through the second bearing 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com