Sample weighing method for automatic industrial analysis instrument

An industrial analysis and sample technology, applied in the direction of removing a certain component weighing, instruments, and using material absorption weighing, etc., to solve problems such as changes in the center of gravity, affecting the weighing of the weighing balance, and increasing the cumulative error of rounding. Achieve the effect of reducing participation and waiting time, saving weighing time, and reducing weighing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

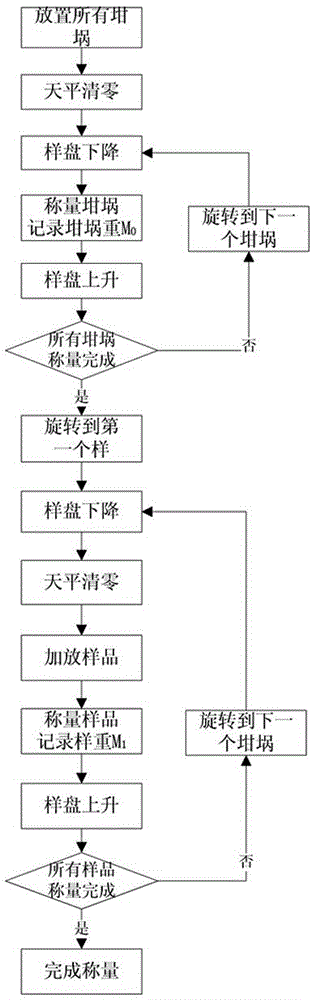

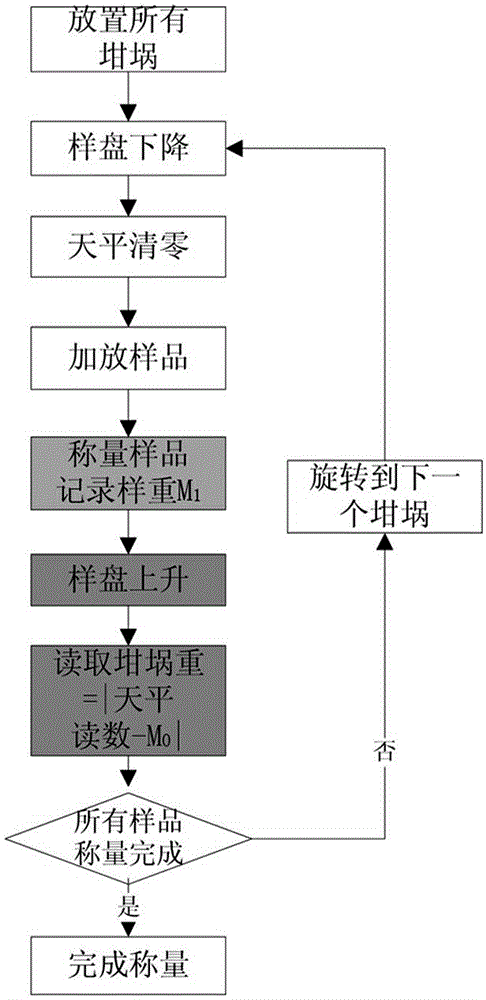

[0028] The present invention will be further described in detail below with reference to the drawings and specific embodiments of the specification.

[0029] The method for weighing samples on automated industrial analytical instruments of the present invention includes the following steps:

[0030] S1: Place all sample containers;

[0031] S2: The sample plate drops, and the weighing balance is cleared;

[0032] S3: Add the sample to the sample container, use the sample balance to directly weigh the sample to obtain the sample weight, and record it as the sample weight M 1 , The sample plate rises;

[0033] S4: Take the sample container out of the sample balance. At this time, the absolute value of the negative value of the weight obtained on the sample balance is the weight of the sample container, denoted as M 0 ;

[0034] S5: M obtained by weighing 0 And M 1 , Participate in the calculation of indicators.

[0035] In this way, the weight of the sample can be obtained at one time witho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com