Flexible temperature sensor and preparation process thereof

A temperature sensor and sensor technology, applied in the sensor field, can solve the problems of large size, limited service life and complex structure of the temperature sensor, and achieve the effects of strong integrity, stable operation and accurate graphic structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

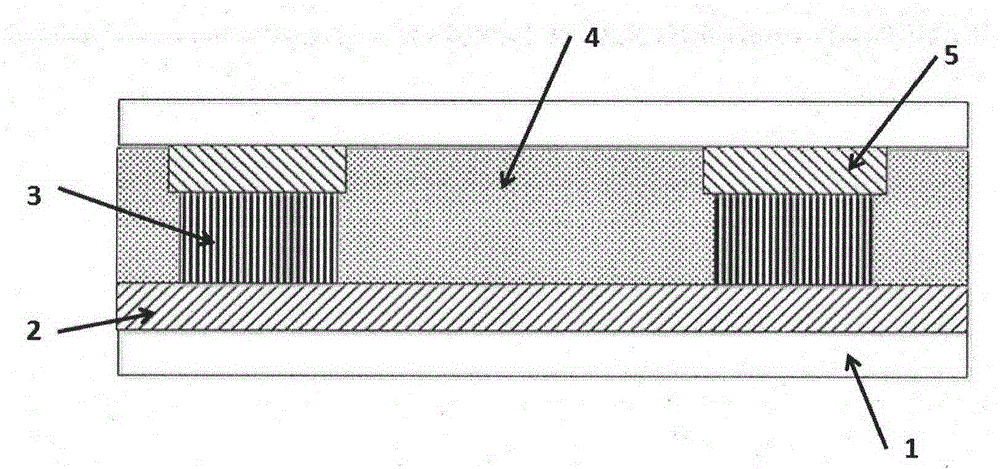

[0028] refer to figure 1 , showing a schematic structural view of the first embodiment of the flexible temperature sensor unit, including:

[0029] Flexible substrate 1: the flexible substrate material at the top and bottom of the sensor; used for the bearing of the entire flexible sensor element; the flexible substrate is natural rubber, polyurethane, silicone rubber, fluororubber and styrene-ethylene-butadiene- Materials such as styrene, styrene-butadiene-styrene or polyisobutylene polymers;

[0030] Lower electrode 2: the lower electrode of the sensing array located on the underlying substrate material; used to lead out one end of the temperature-sensitive resistor to test its resistance value change;

[0031] Temperature-sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com