Flexible sensor preparation process

A flexible sensor and preparation process technology, applied in the field of sensors, can solve the problems of complex process, expensive equipment, difficult to prepare products in a large area, etc., and achieve the effects of accurate graphic structure, good adaptability and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

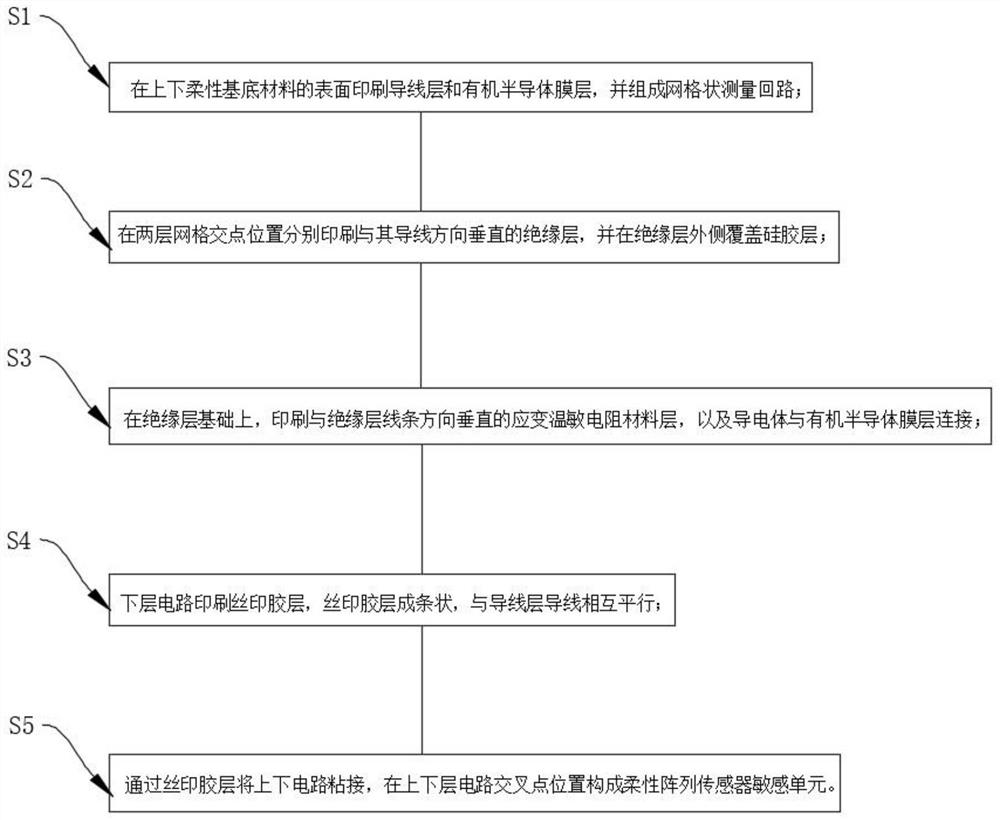

Method used

Image

Examples

Embodiment 1

[0035] Example 1: 100 mg of graphene oxide film with a thickness of 100 μm obtained by suction filtration was placed in a desiccator, and a petri dish containing 200 μL of 3-aminopropyltriethoxysilane was placed in the desiccator, and sealed at 180 The reaction was carried out at ℃ for 3h. After the reaction, the obtained modified reduced graphene oxide film was taken out and vacuumed for three times. A 500 mg / L aqueous solution of methylene blue was prepared and applied dropwise onto the surface of one side of the silane-modified reduced graphene oxide film at a dosage of 100 μL / cm2. After natural drying, it was immersed and washed in deionized water for 3 times, and after drying, a modified reduced graphene oxide film adsorbed with a medium material was obtained. Glucose oxidase is dissolved in phosphate buffer (pH=7.2), the concentration is 10-50mg / ml, and then mixed with 1% chitosan solution (solvent is 2% acetic acid aqueous solution) in a volume ratio of 1:2 to obtain ...

Embodiment 2

[0036] Embodiment 2: Embodiment 2 is basically the same as the above-mentioned embodiment, except that methyltriethoxysilane is used as the silane-modified reactant. Since the modified reduced graphene oxide film modified with silane is hydrophobic, when the organic dye is adsorbed, the organic dye needs to be dissolved in an organic solvent (such as ethanol), and then drop-coated.

[0037] To sum up, the present invention firstly utilizes silane vapor to simultaneously reduce and crosslink the graphene oxide film to prepare a modified reduced graphene oxide film with both electrical conductivity and mechanical strength; The surface of the graphene film adsorbs the medium material to form a medium layer on the modified reduced graphene oxide film. This method avoids the complicated electropolymerization process in the formation of the traditional medium layer, the preparation method is simple, the medium layer can be closely combined with the electrode body, and the flexibilit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com