Reaction kettle

A technology of reaction kettle and kettle body, applied in the field of petroleum and exploration, can solve problems such as difficulty in leak detection and maintenance, and achieve the effects of easy maintenance and leak detection, reduction of heat loss, and accurate experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

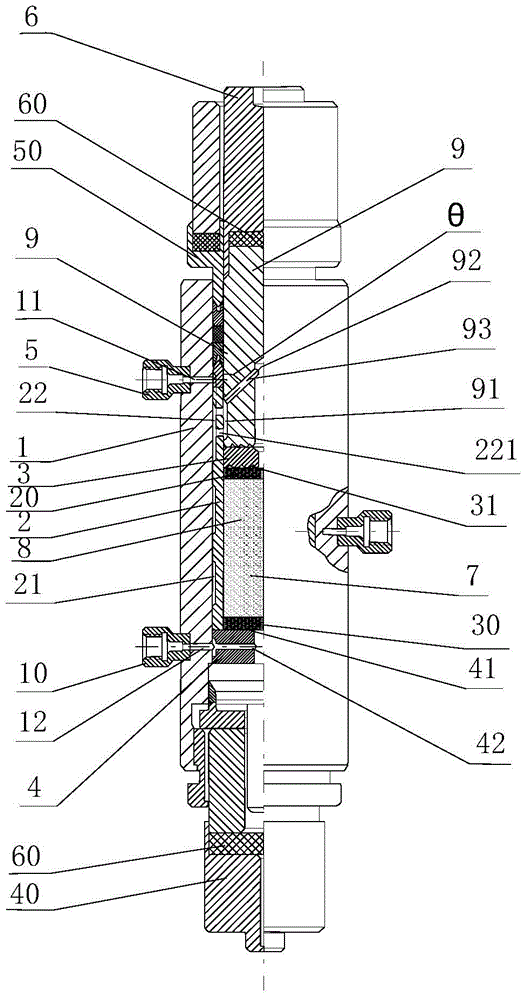

[0023] Such as figure 1 As shown, the reaction kettle is used to heat the source rock sample 8 at a high temperature, and analyze the source rock sample 8 that has been heated, that is, to analyze various products (such as (for oil, gas, water, etc.), determine the percentage content of each product in the entire source rock sample 8, so as to determine the composition of the source rock sample 8.

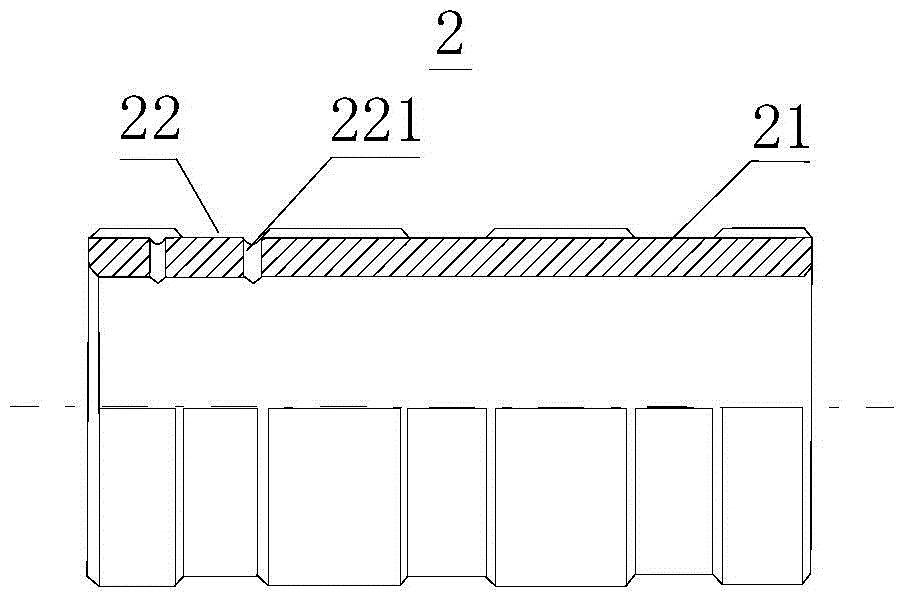

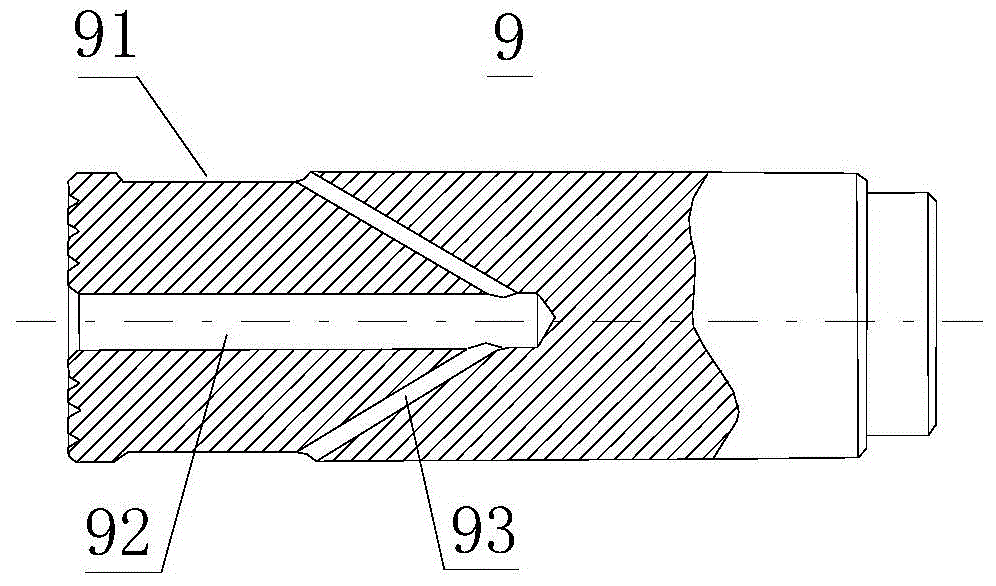

[0024] In the embodiment of the present application, the reaction kettle includes a kettle body shell 1 , a sleeve assembly 2 , a space regulator 3 , a fixed lead 4 and a first joint assembly 5 . Wherein, the kettle shell 1 is roughly columnar, and the inside is a hollow structure. A first flow hole 11 is opened on the side wall of the tank shell 1 . The first flow hole 11 is arranged on the side wall of the kettle body shell 1, thereby facilitating the connection and disasse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com