Thermal Displacement Correction Training Unit For Machine Tool

一种训练装置、热位移的技术,应用在宇宙航行条件的模拟装置、模拟机、运输和包装等方向,能够解决经济难以准备机床热位移修正训练、工序影响、机床价格昂贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

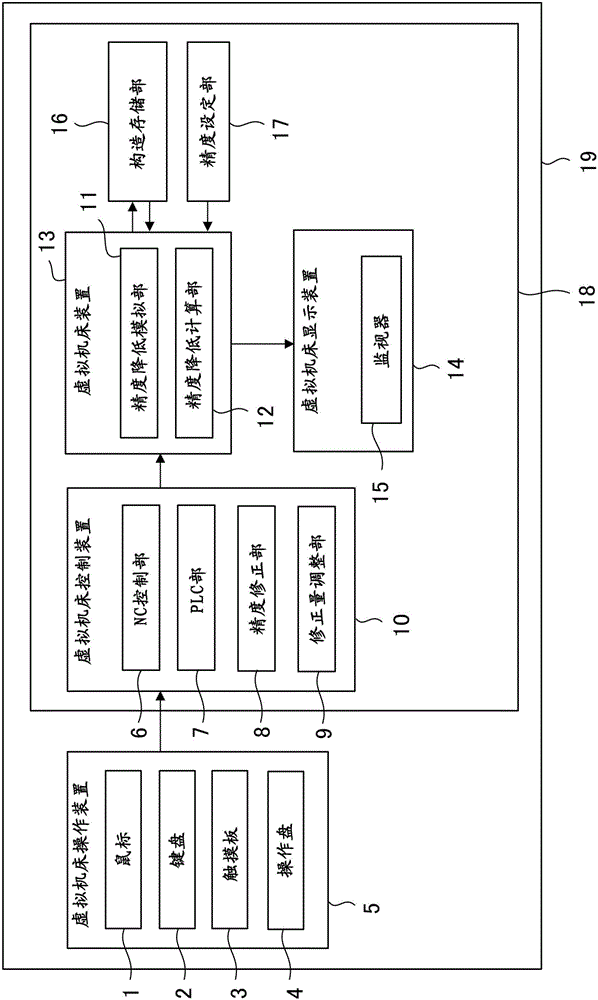

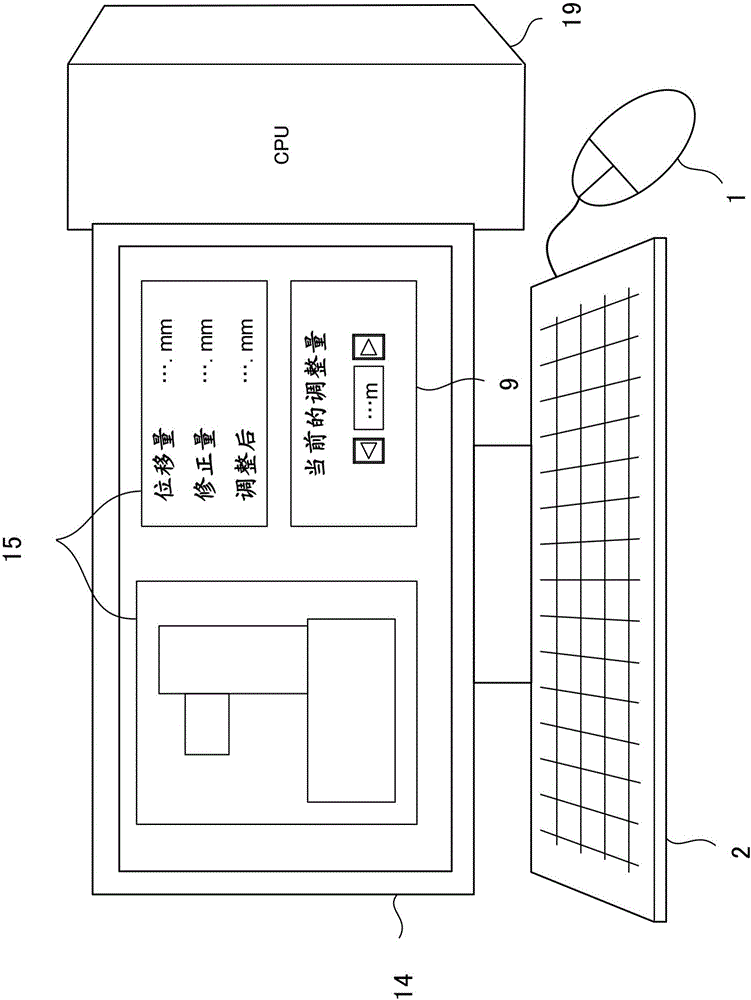

[0019] figure 1 It is a functional block diagram of the thermal displacement correction training device of the present invention. A thermal displacement correction training device 19 related to thermal displacement correction which does not require an actual machine tool is prepared. The operator of the machine tool uses the thermal displacement correction training device 19 to learn the method of thermal displacement correction and the adjustment method of thermal displacement.

[0020] The thermal displacement correction training device 19 includes a virtual machine tool control device 10 , a virtual machine tool device 13 , and a virtual machine tool display device 14 on a computer 18 .

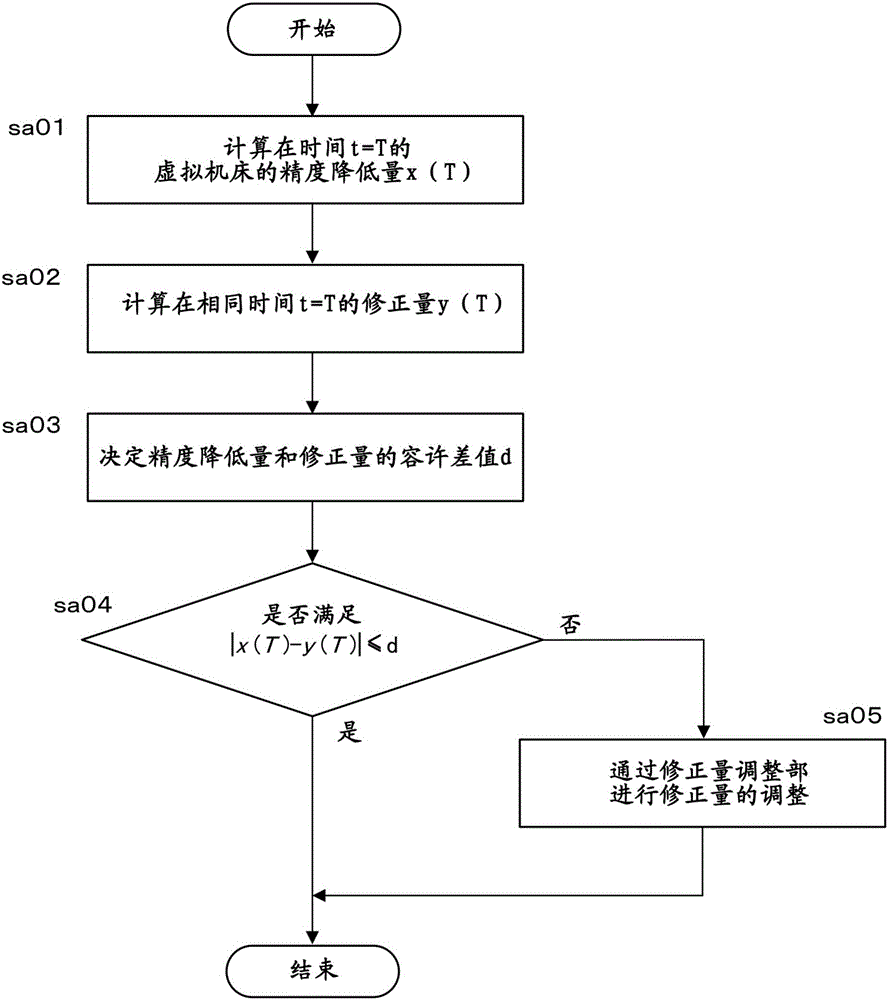

[0021] For the training of machine tool operators, the virtual machine tool device 13 of the thermal displacement correction training device 19 calculates a virtual model of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com