Patents

Literature

37 results about "Virtual machine tool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

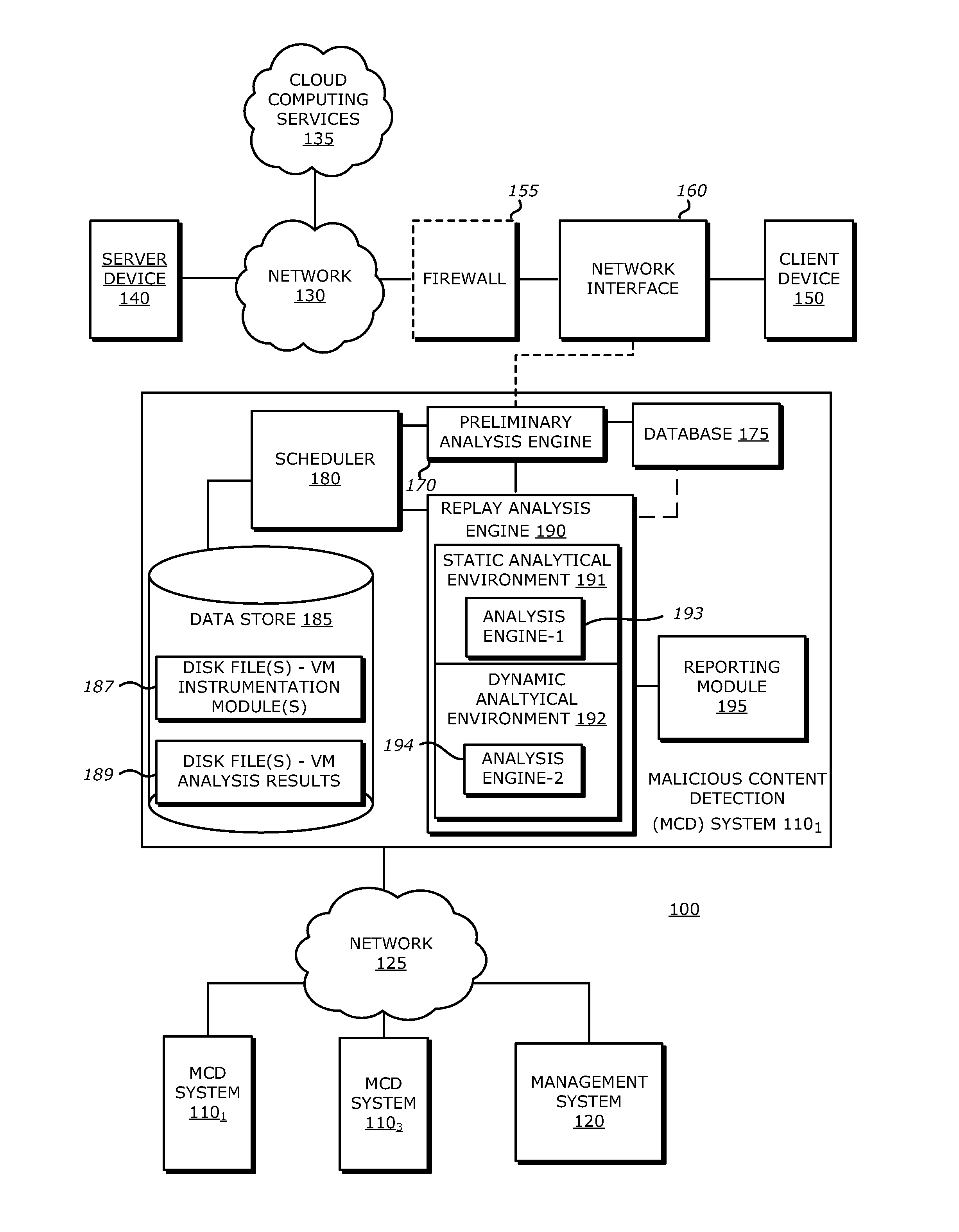

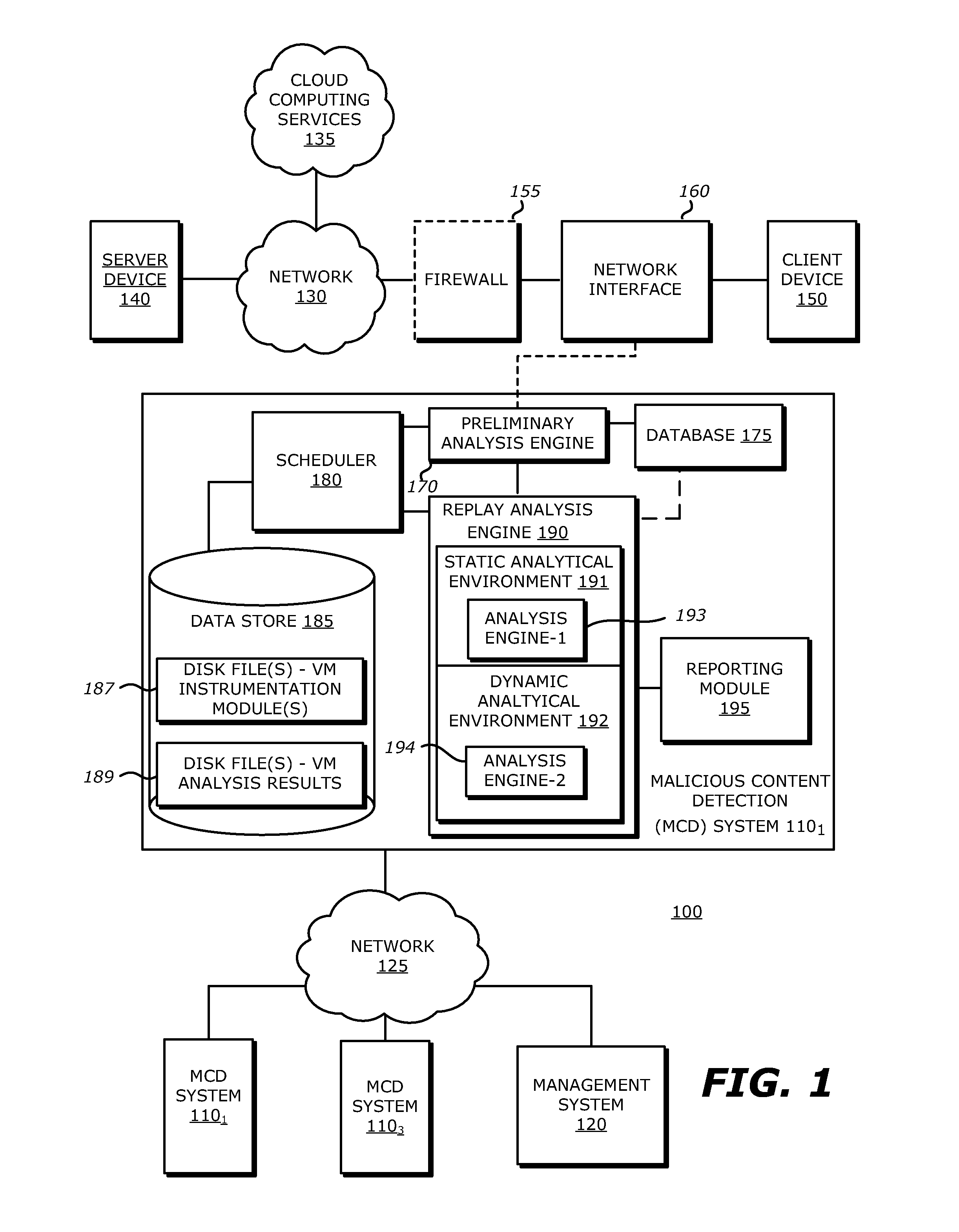

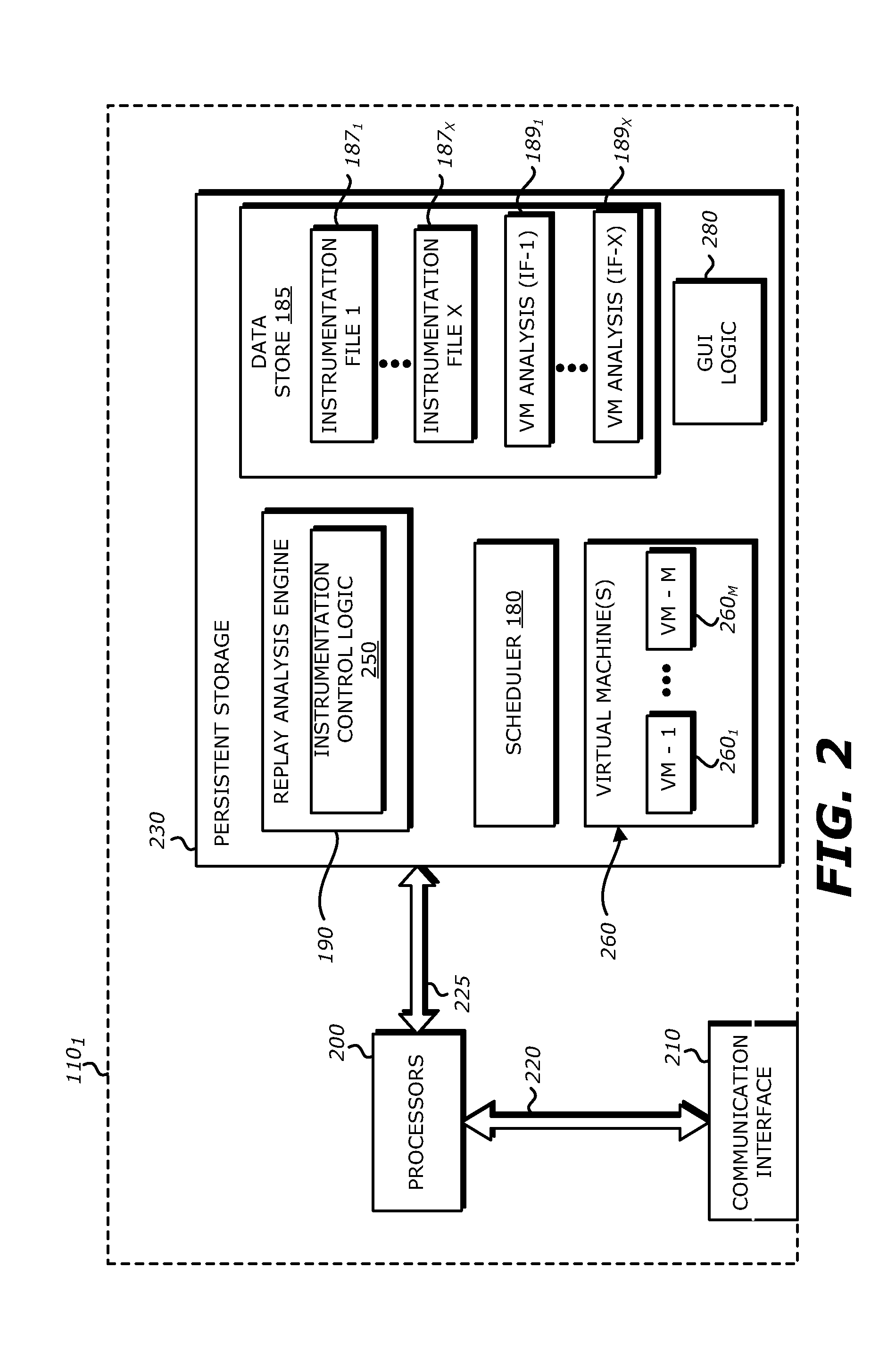

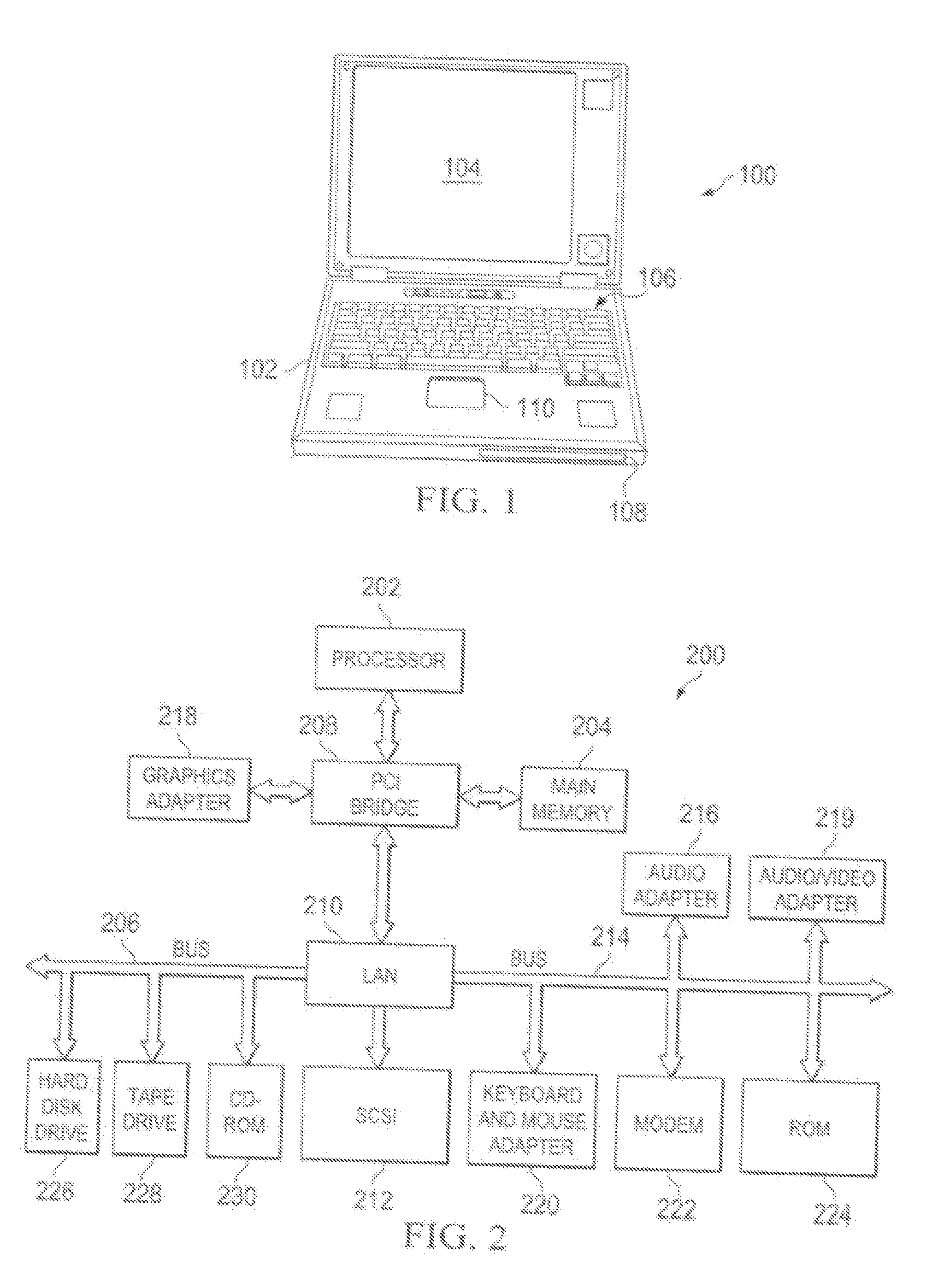

System, Apparatus and Method for Using Malware Analysis Results to Drive Adaptive Instrumentation of Virtual Machines to Improve Exploit Detection

According to one embodiment, an electronic device comprises a memory to store information and a processor. The processor is adapted to receive information associated with content such as network traffic, to process the stored information and to conduct operations on the content. These operations may comprise determining, by a virtual machine processed by the processor, an occurrence of an event during malware analysis of an object associated with the content, and dynamically altering a virtual machine instrumentation of the virtual machine based on information associated with the event.

Owner:FIREEYE SECURITY HLDG US LLC

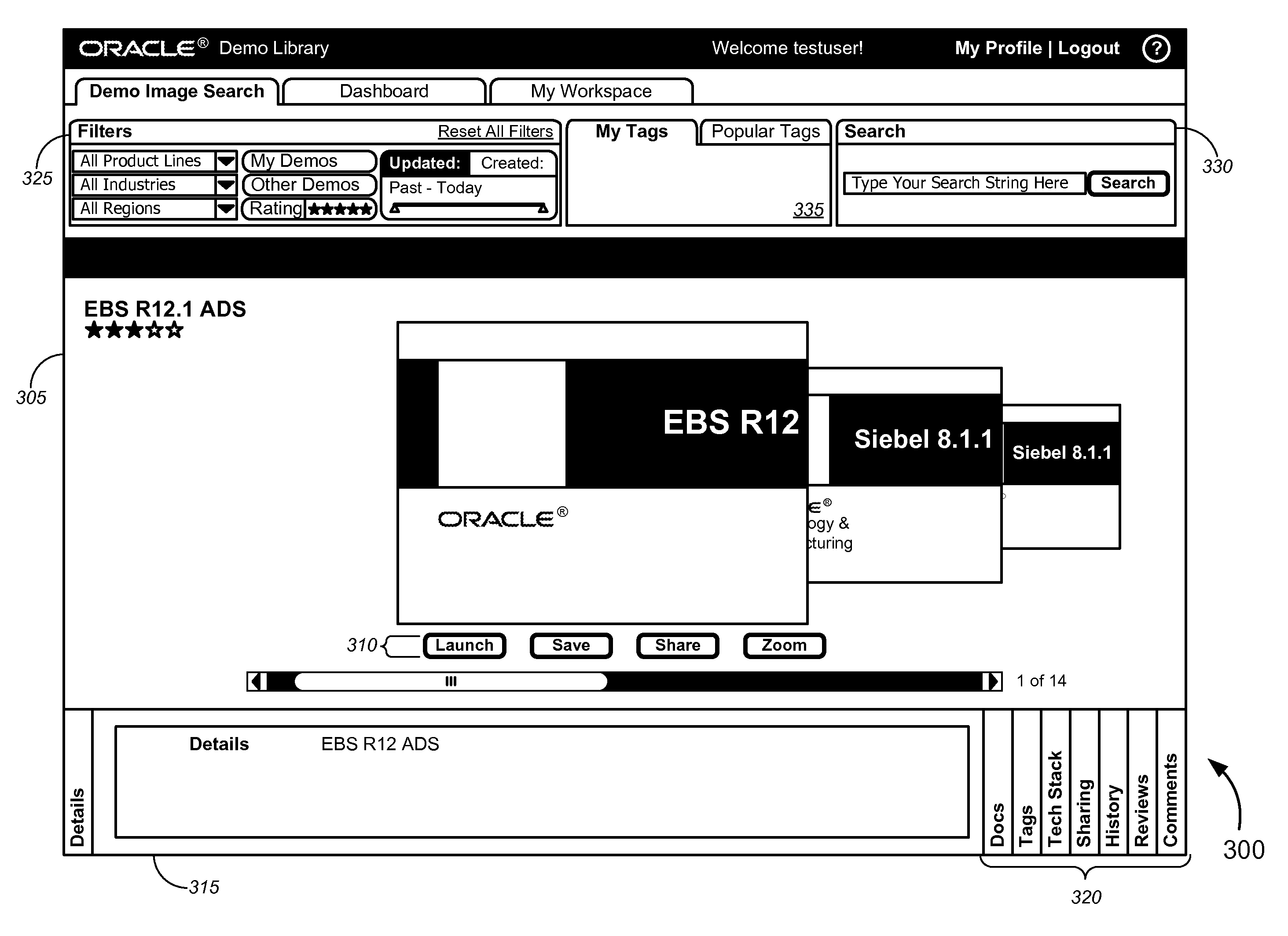

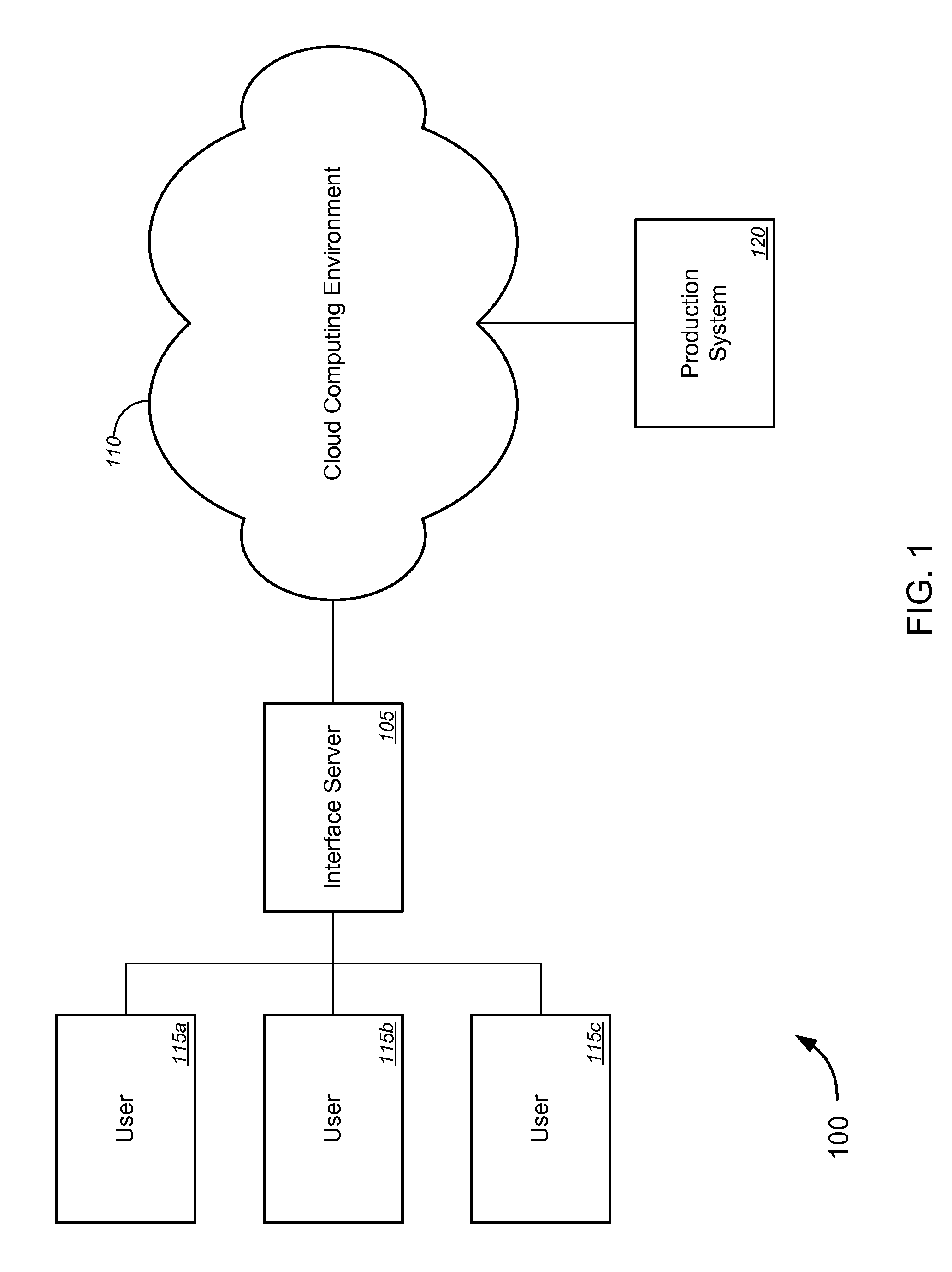

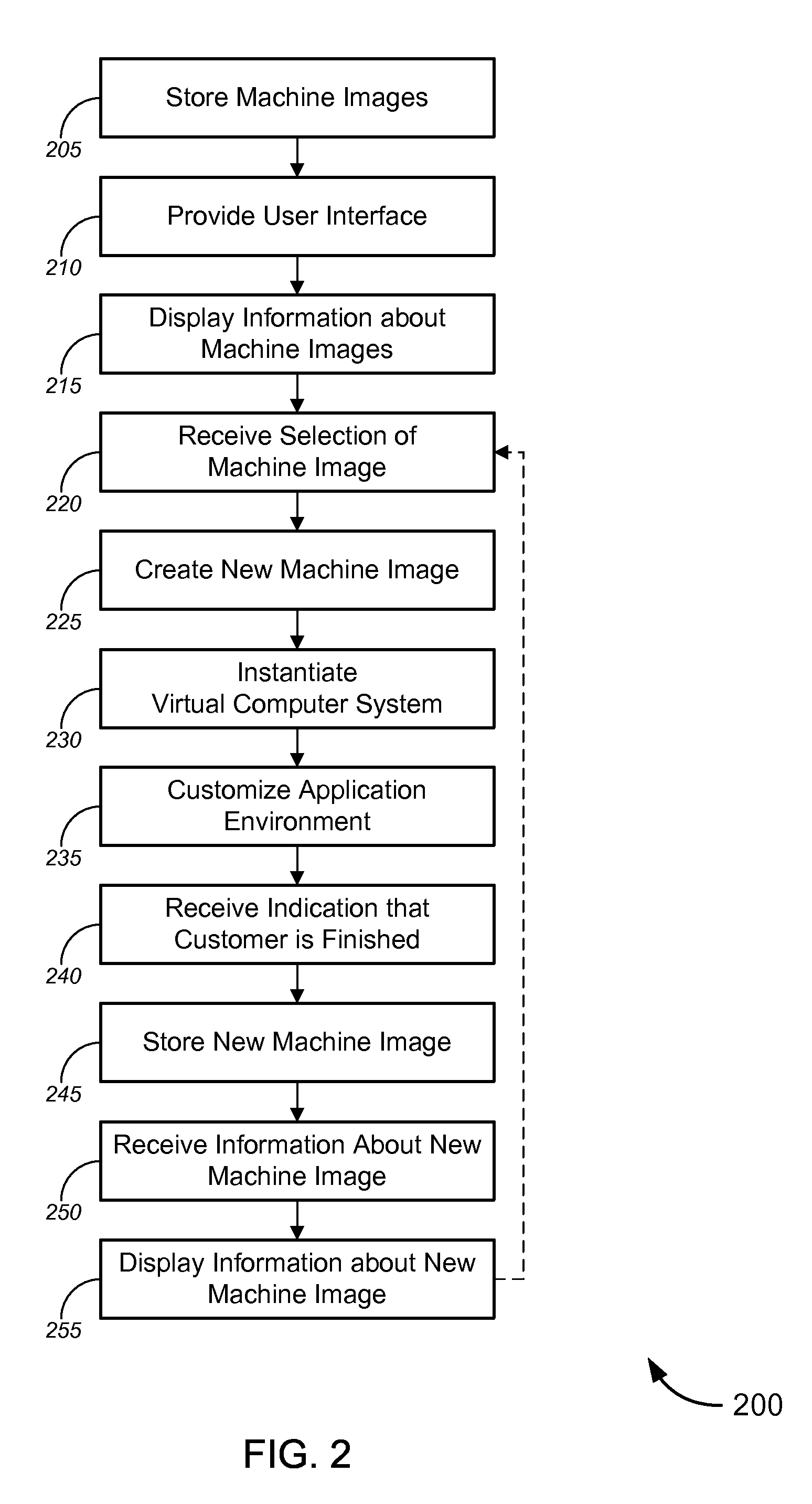

Managing virtual machines

ActiveUS20110055714A1Multiple digital computer combinationsProgram loading/initiatingComputerized systemUser interface

Tools and techniques for managing virtual machines, including without limitation virtual machines running in a cloud computing environment. Certain tools provide a user interface that allows a user to browse machine images to find an image that meets the user's needs. In some aspects, these tools and techniques can provide the ability for users to customize machine images to meet their own needs and / or to share their customized machine images with other users. In other aspects, these tools and techniques can provide users with the ability to export virtual machines for use on an actual computer system.

Owner:ORACLE INT CORP

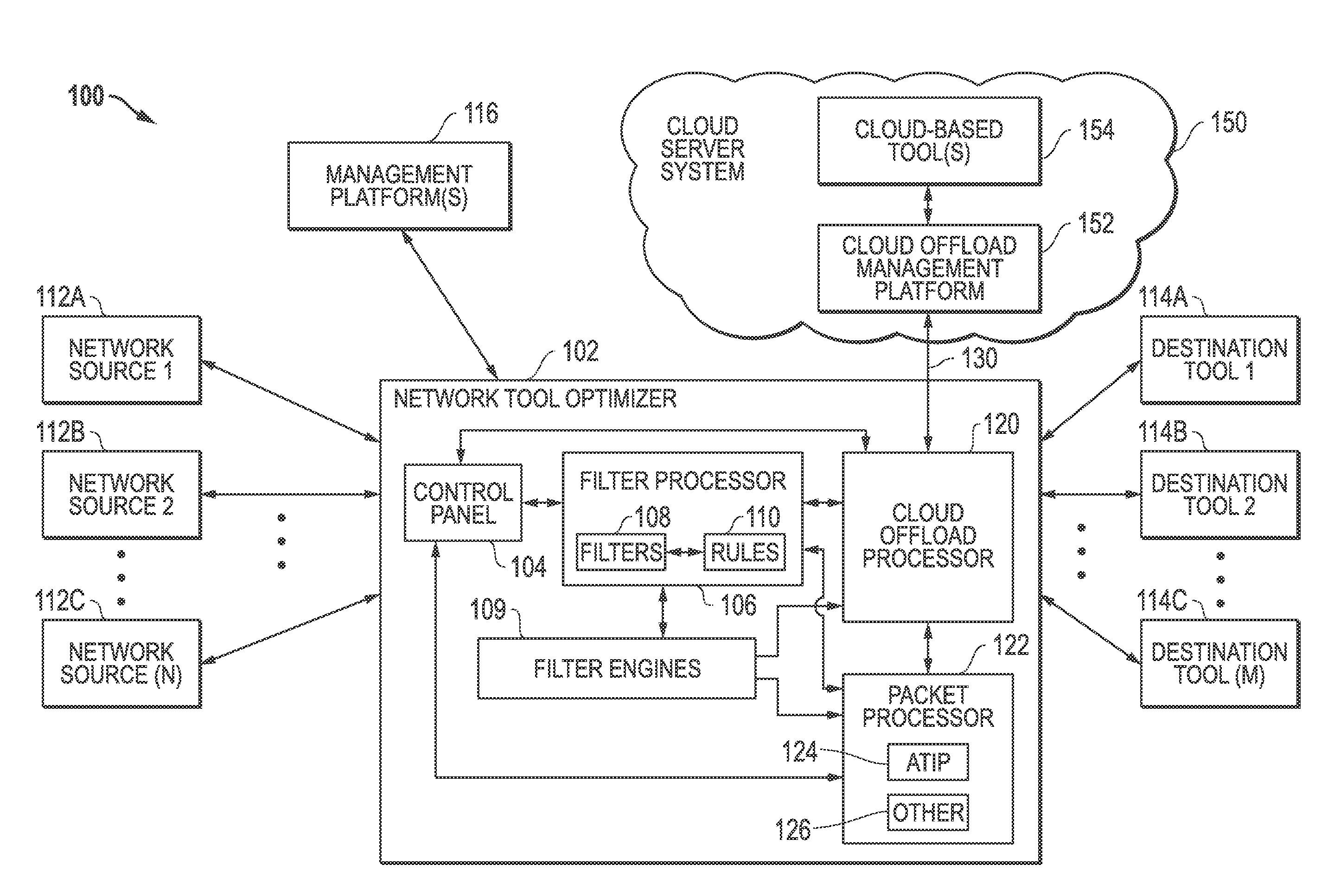

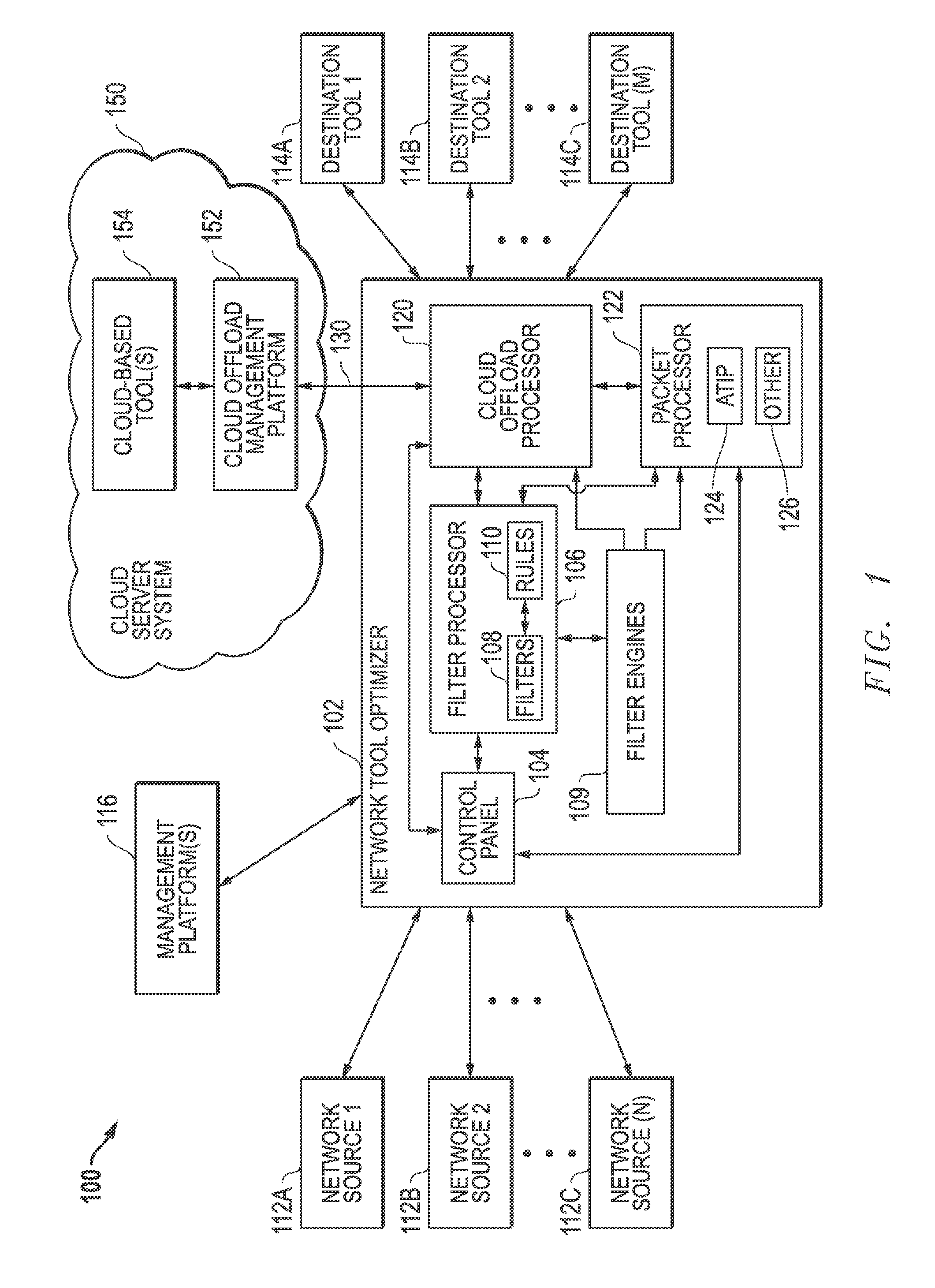

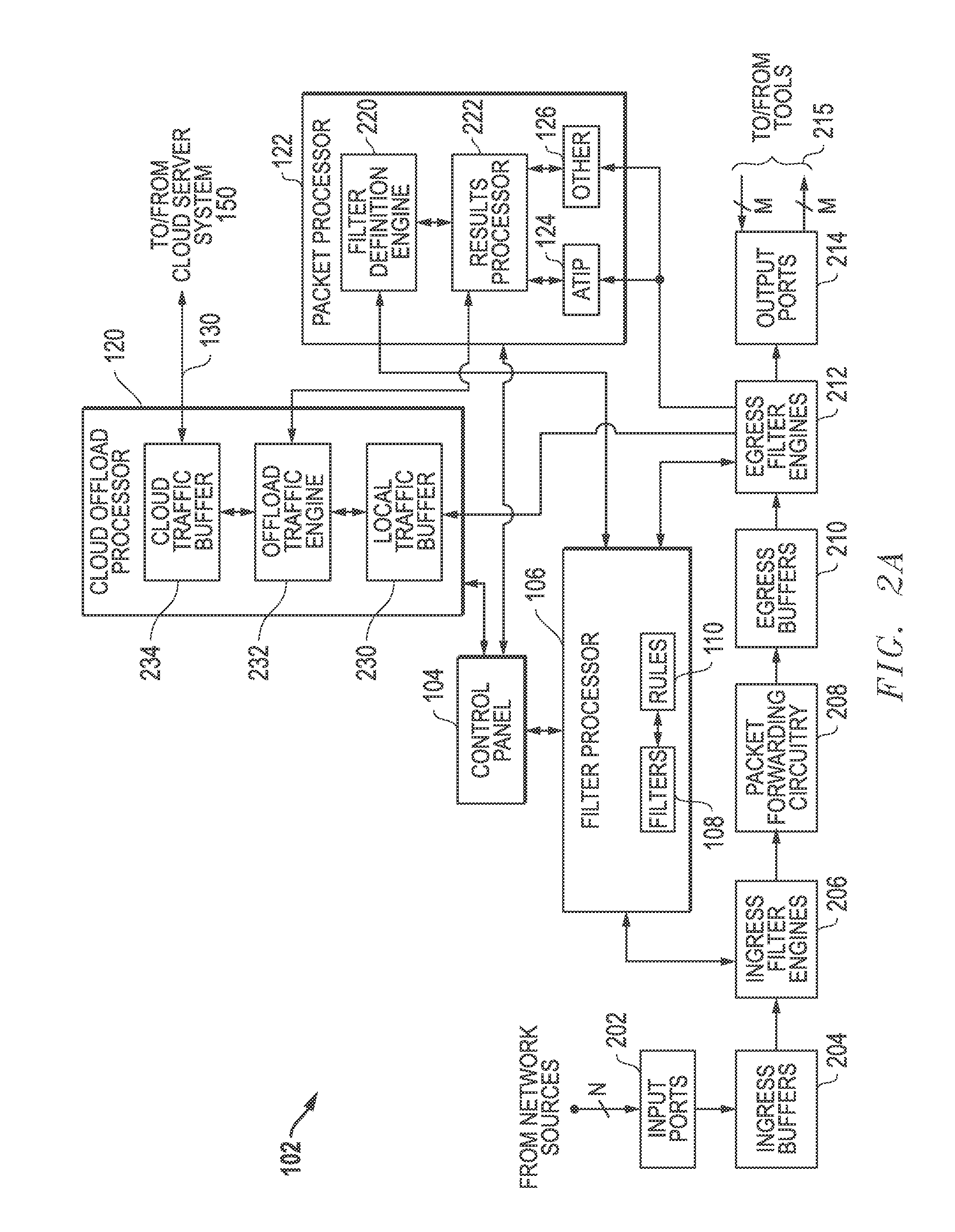

Selective Scanning of Network Packet Traffic Using Cloud-Based Virtual Machine Tool Platforms

Owner:KEYSIGHT TECH SINGAPORE (SALES) PTE LTD

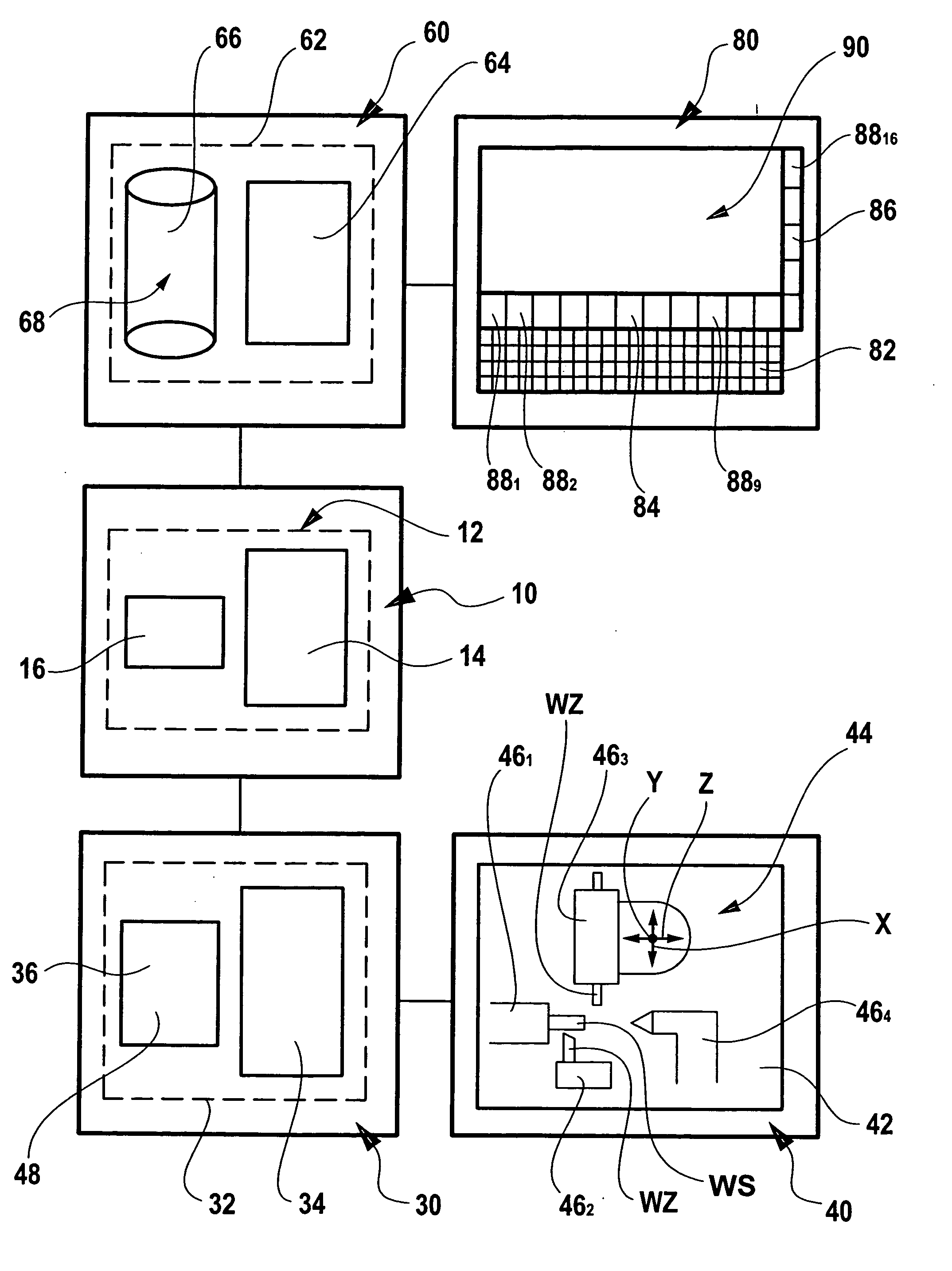

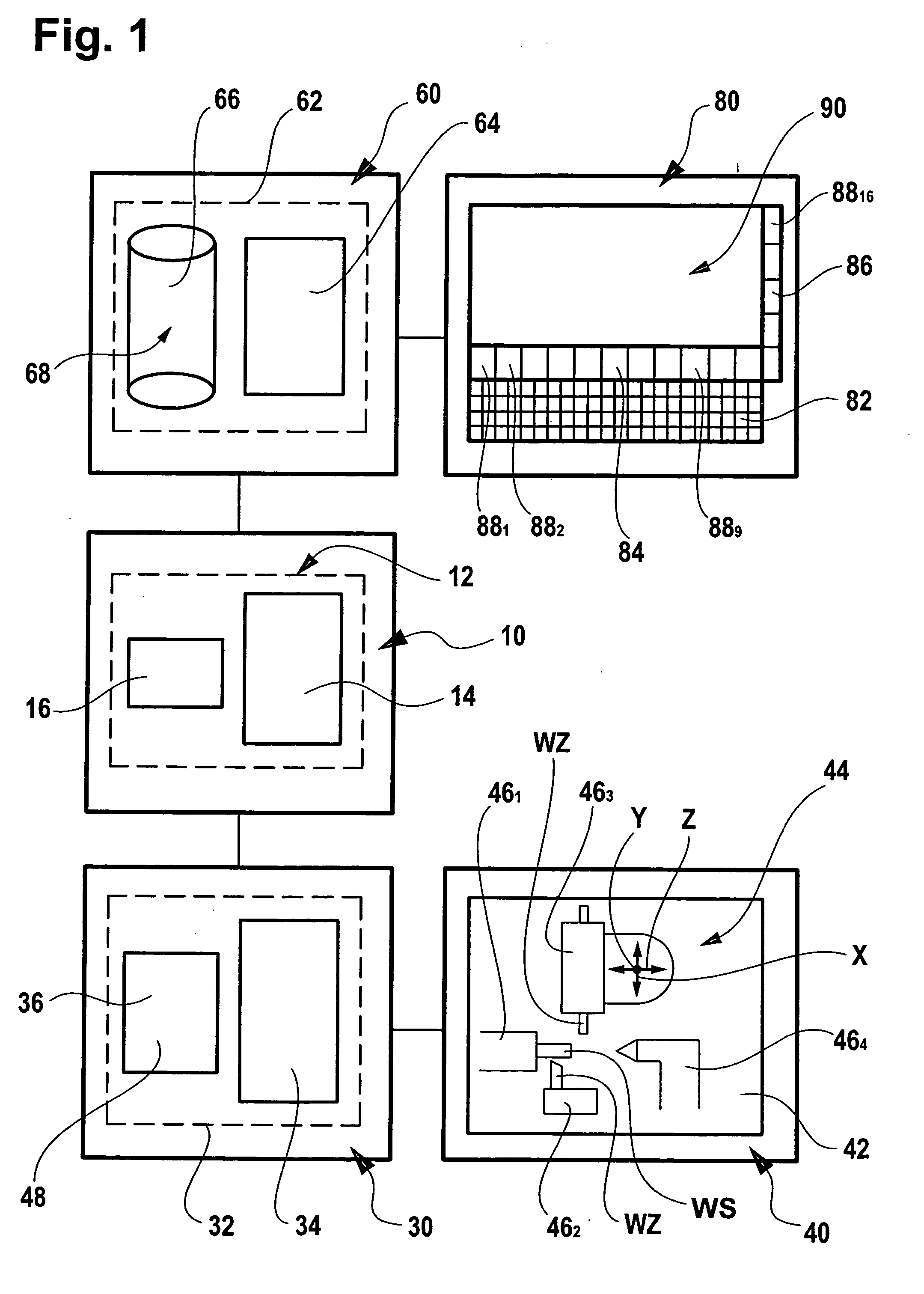

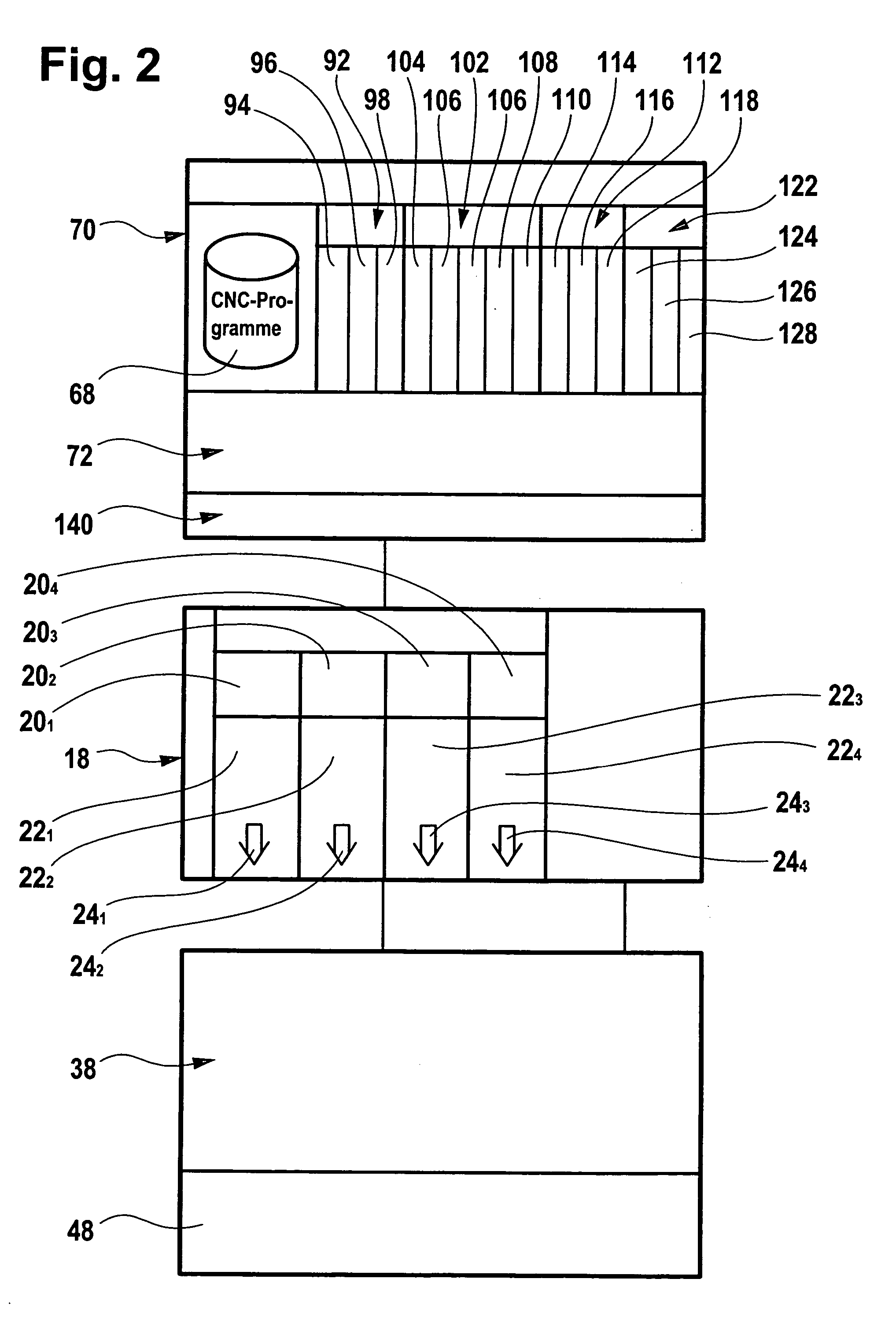

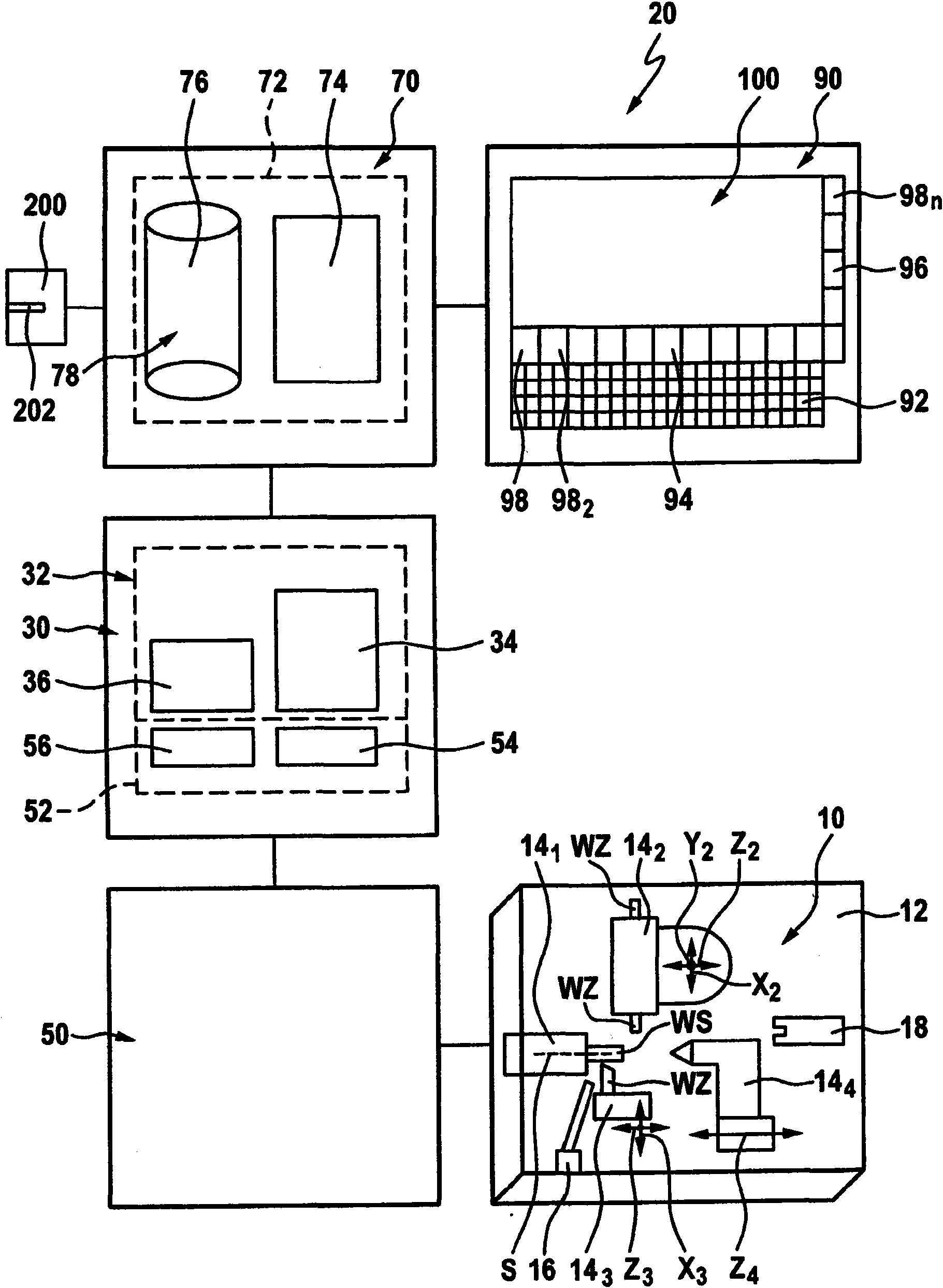

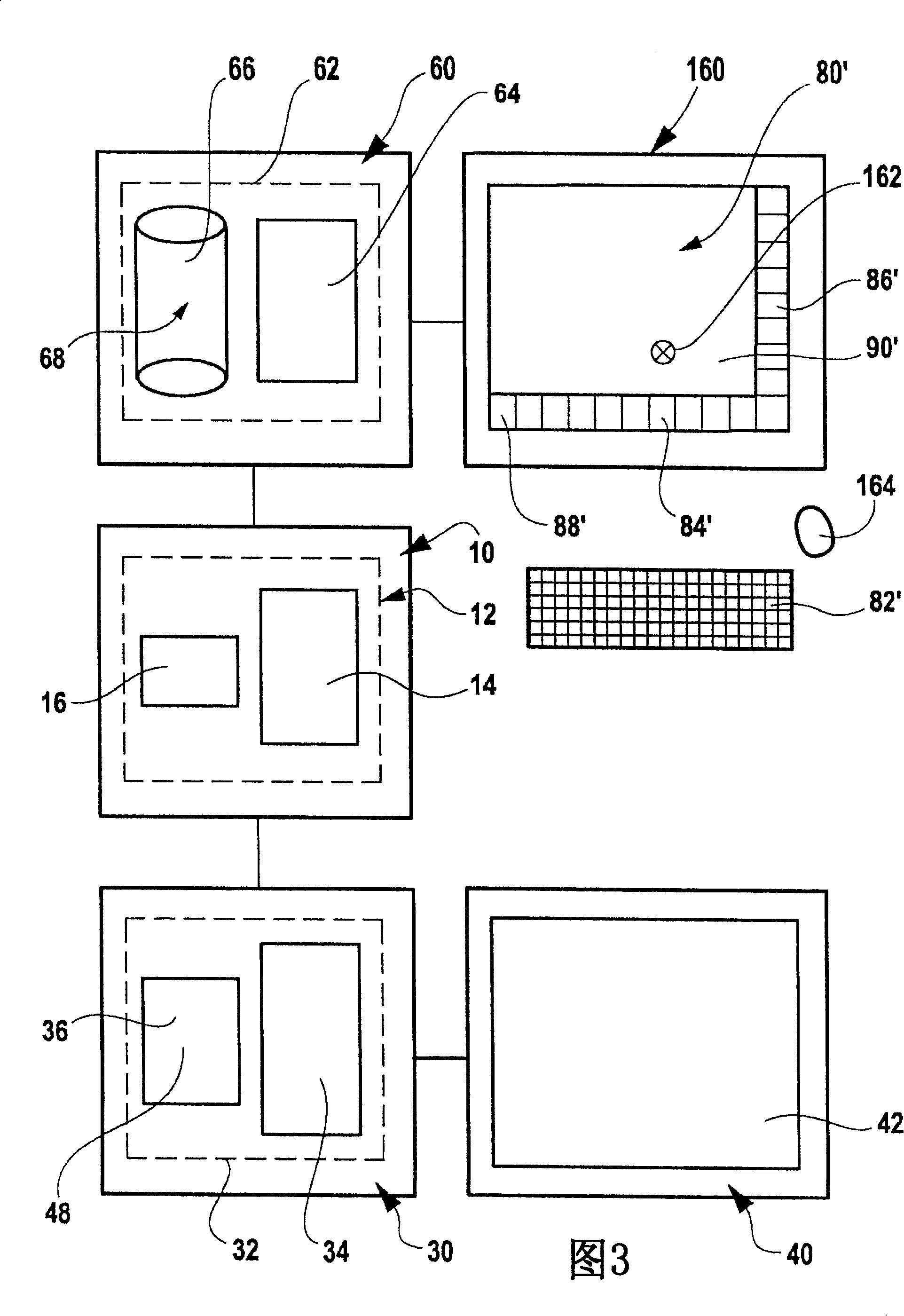

Simulation system

ActiveUS20070061037A1Easy to operateEasy to useProgramme controlSpecial data processing applicationsProgram managementVirtual machining

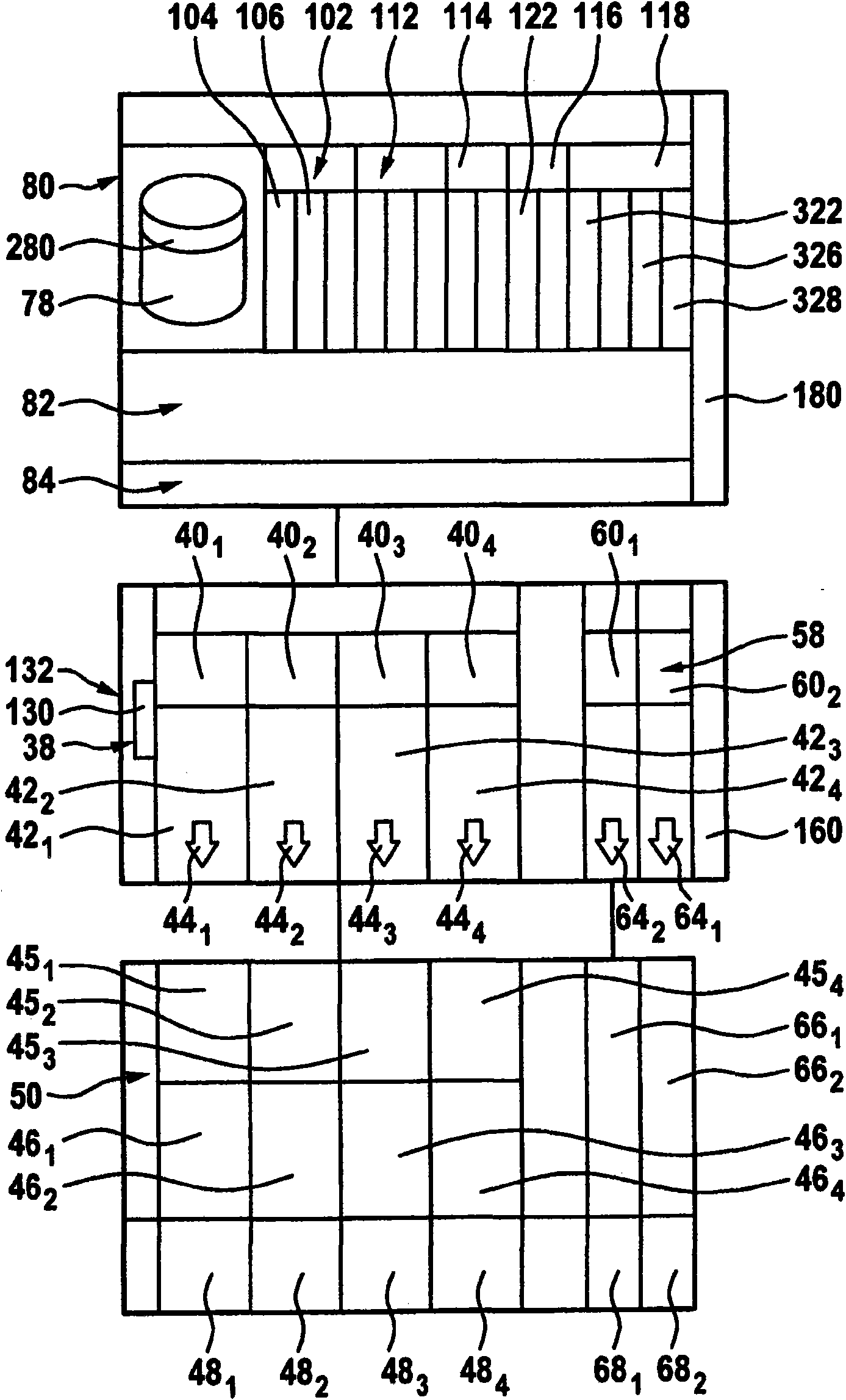

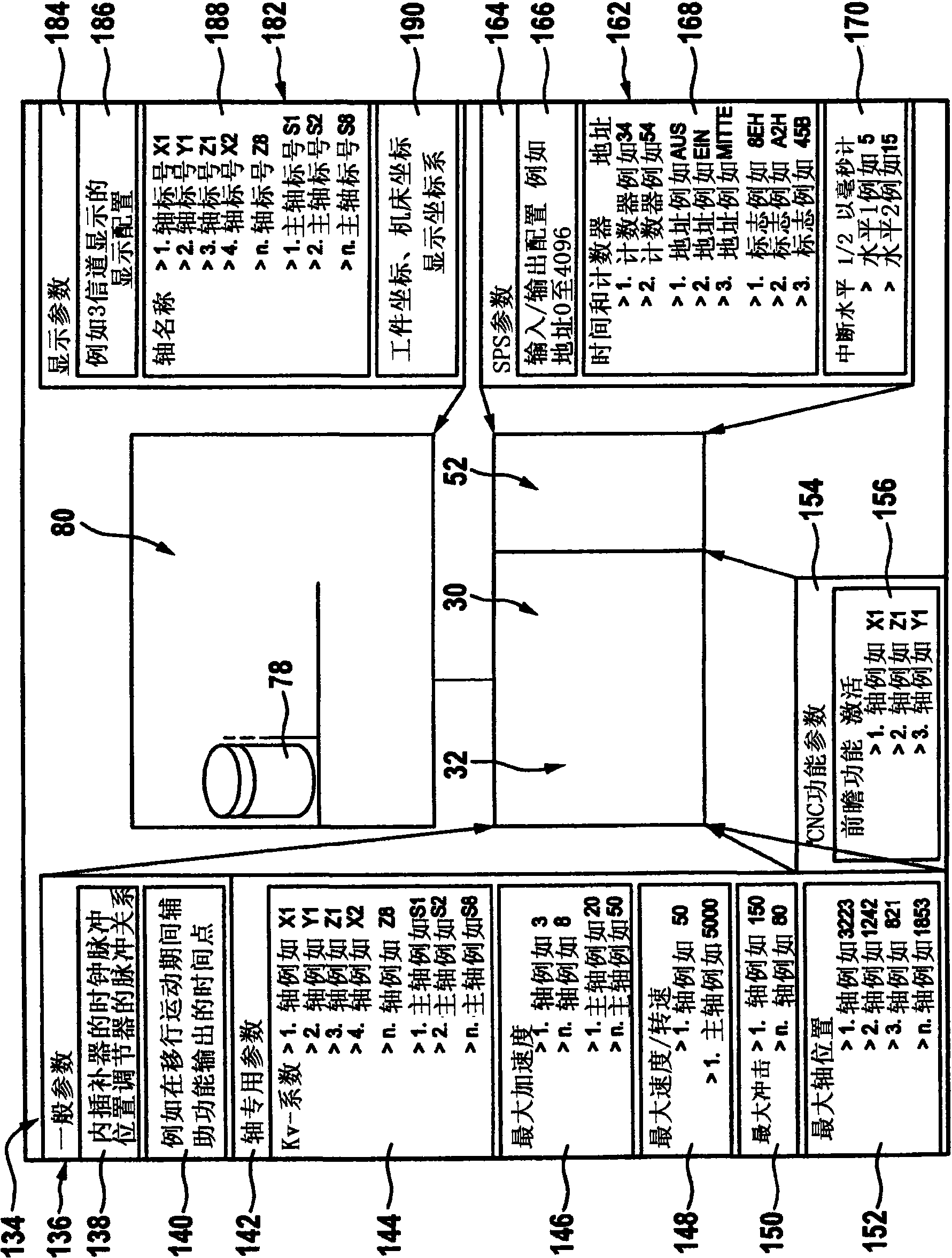

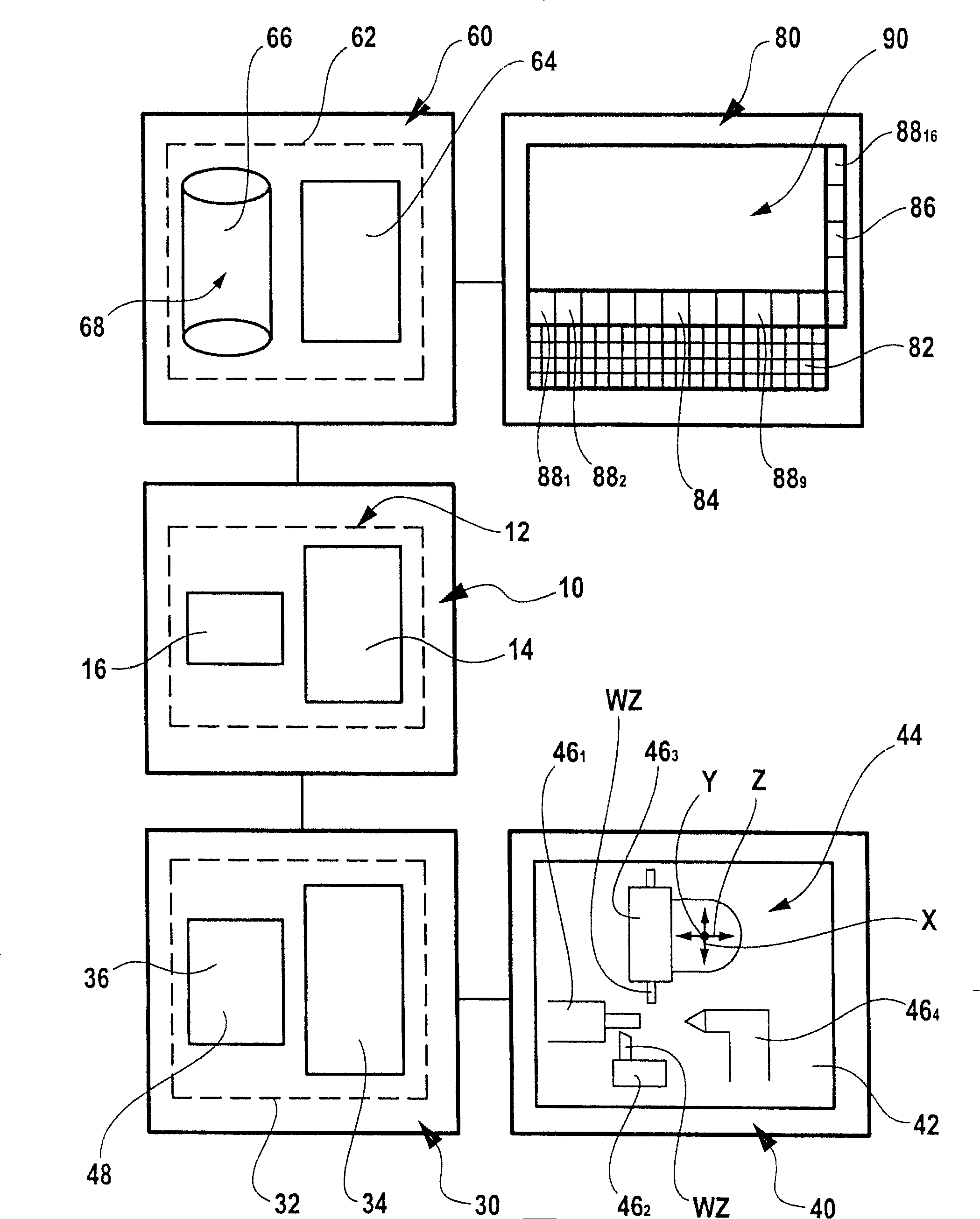

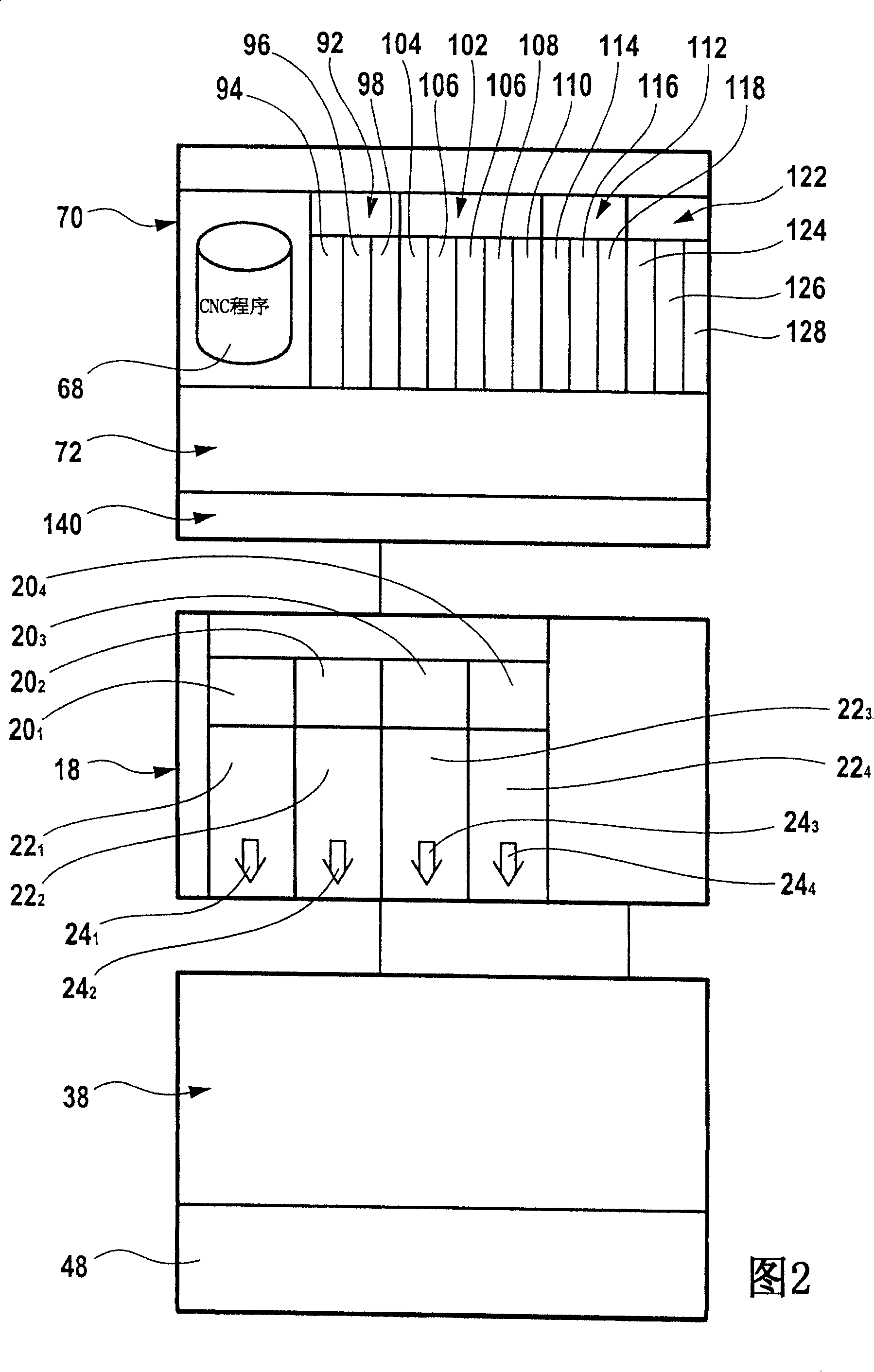

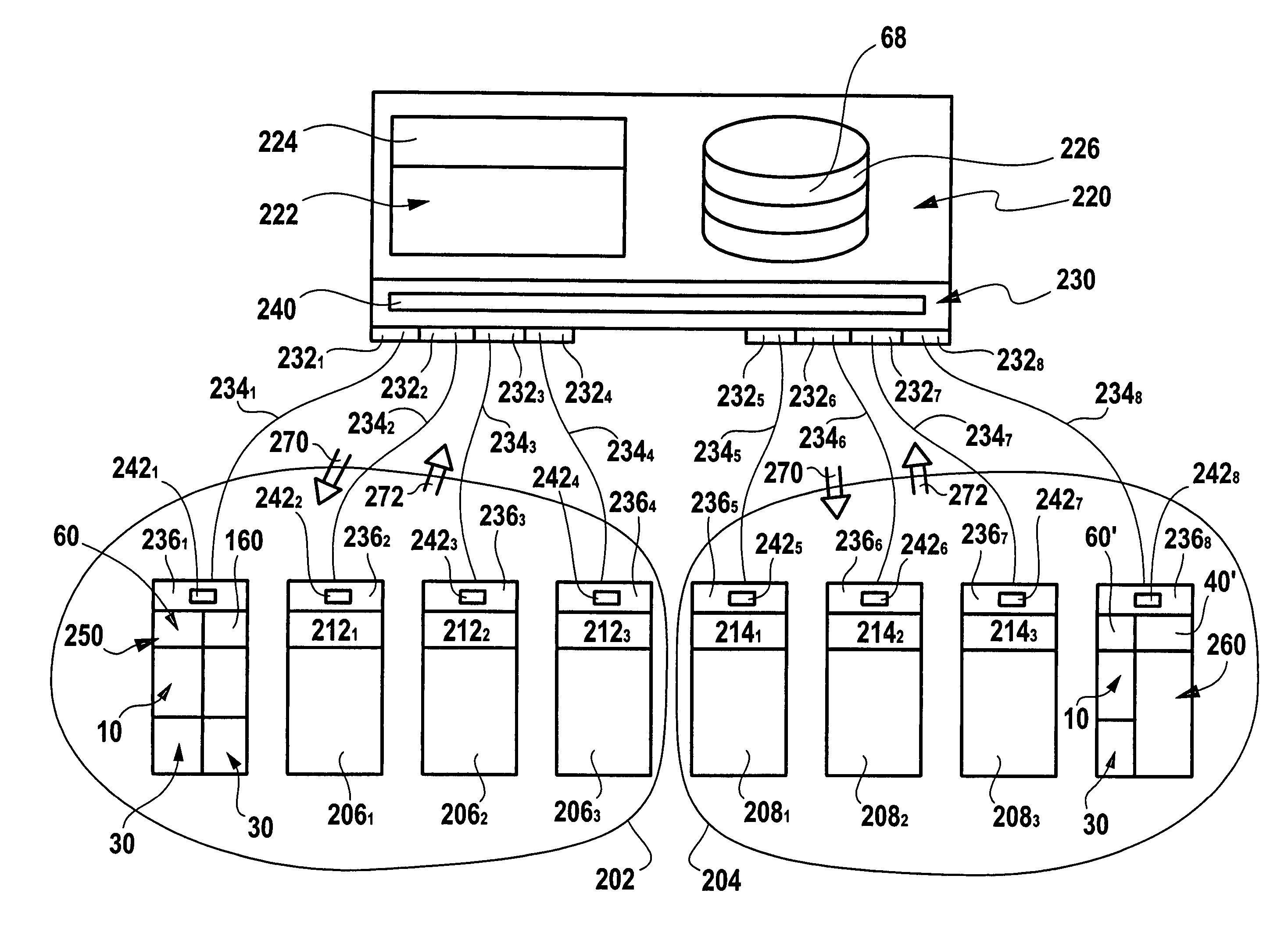

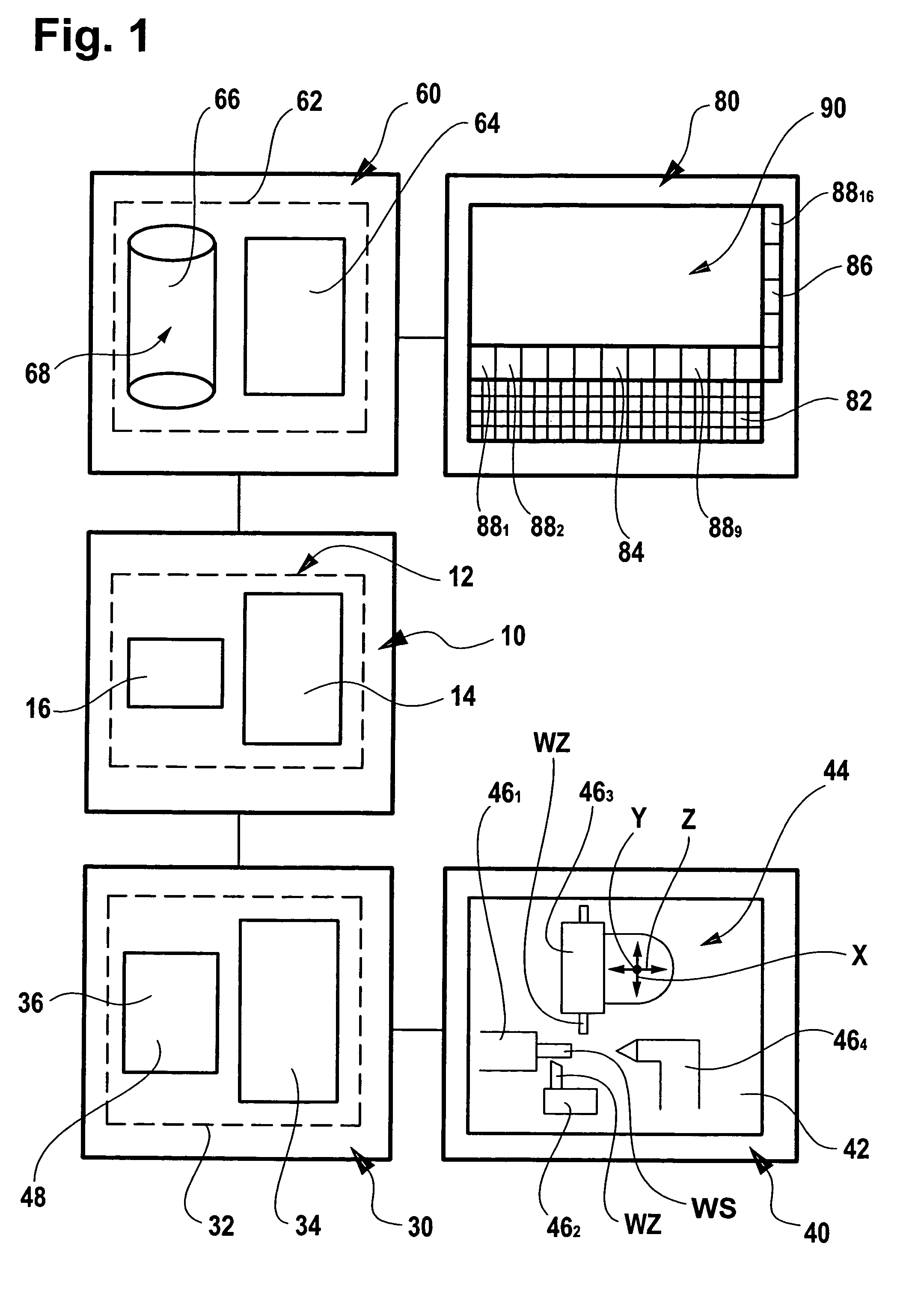

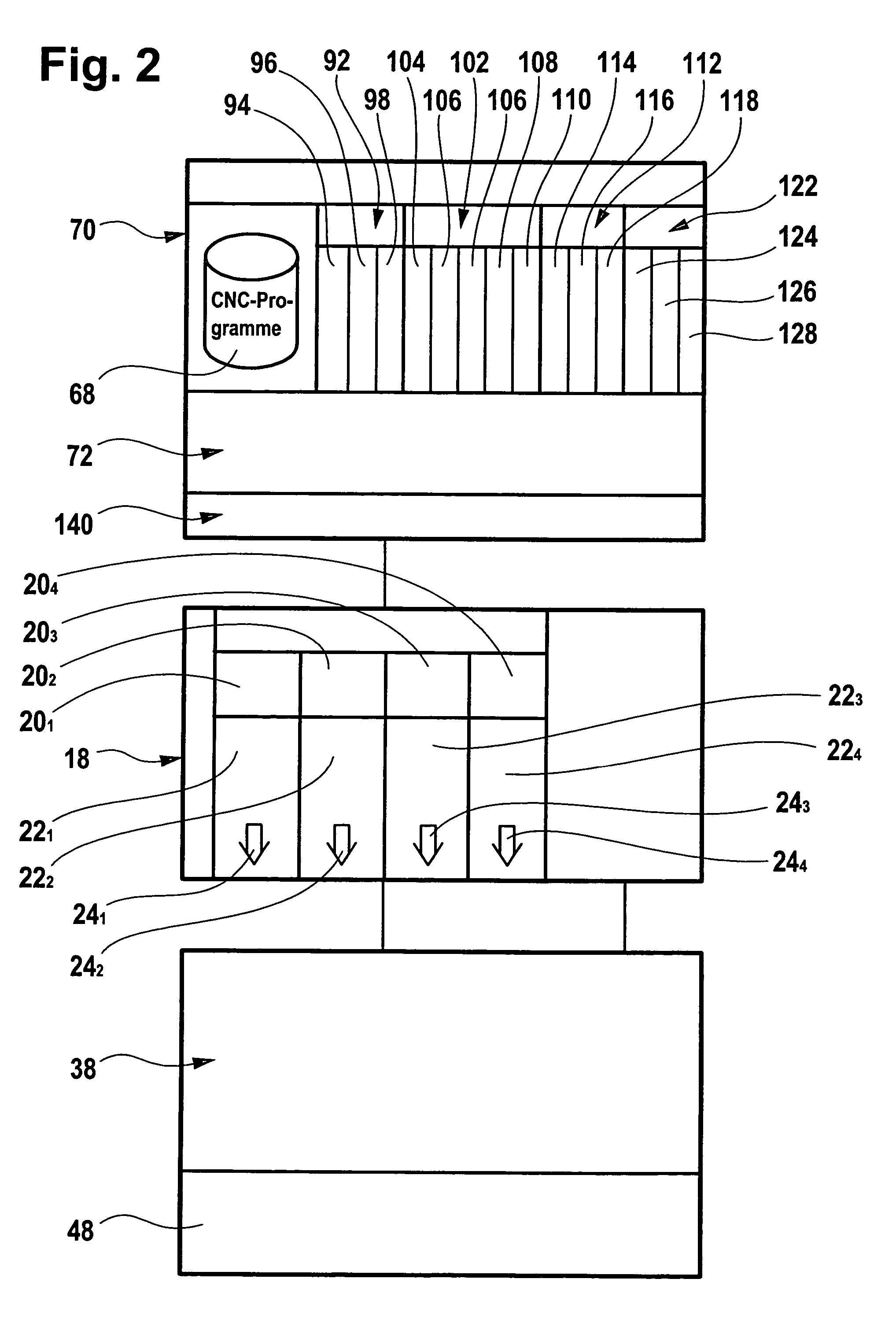

In order to improve a simulation system for representing actions of machining units of a machine tool, in particular actions in the machining of a workpiece, in accordance with a CNC machining program complex by means of at least one first visualization unit in the form of actions of virtual machining units of a virtual machine tool, comprising an action control, which has at least one first data processing unit, which establishes control commands for actions of the virtual machining units by a control program processing CNC blocks of the CNC machining program complex, and a visualization control, which has at least one second data processing unit, which represents actions of the virtual machining units on the first visualization unit by a visualization program on the basis of configuration data of a stored machine model and the control commands determined by the action control, in such a way that it can be operated more easily, it is proposed that the simulation system comprises an operating control with a third data processing unit, which operates the action control by an operating program, and that the operating program has a program management function, which transfers at least program parts of the CNC machining program complex in a workpiece-related manner from said CNC machining program complex stored in a memory of the third data processing unit to the action control for executing said program complex.

Owner:INDEX WERKE GMBH & CO KG HAHN & TESSKY

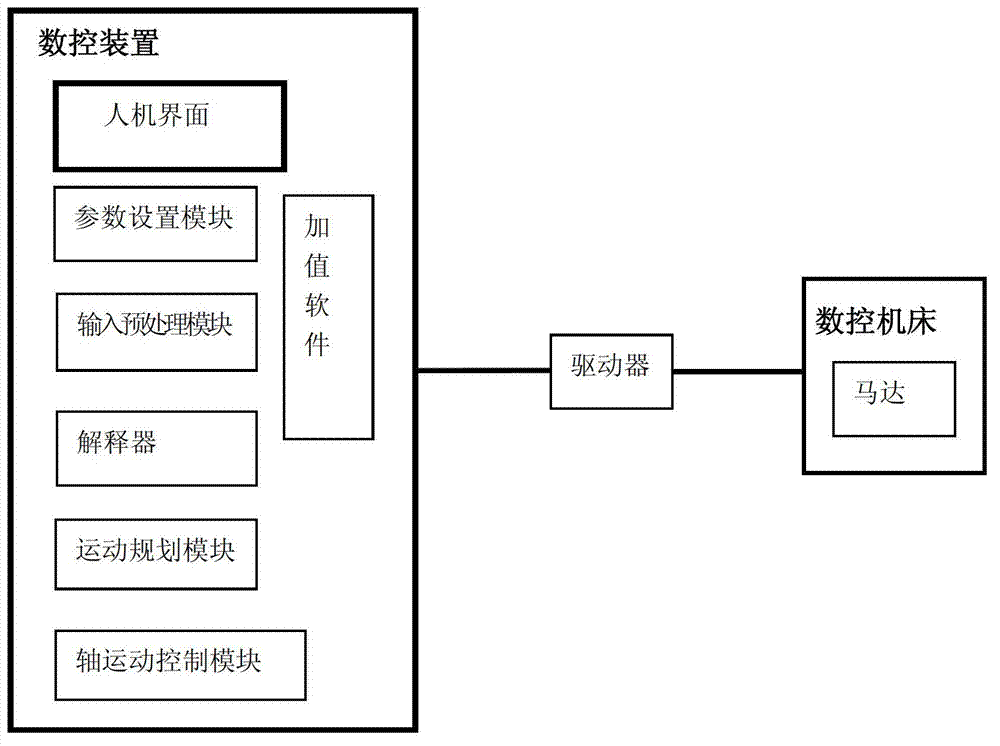

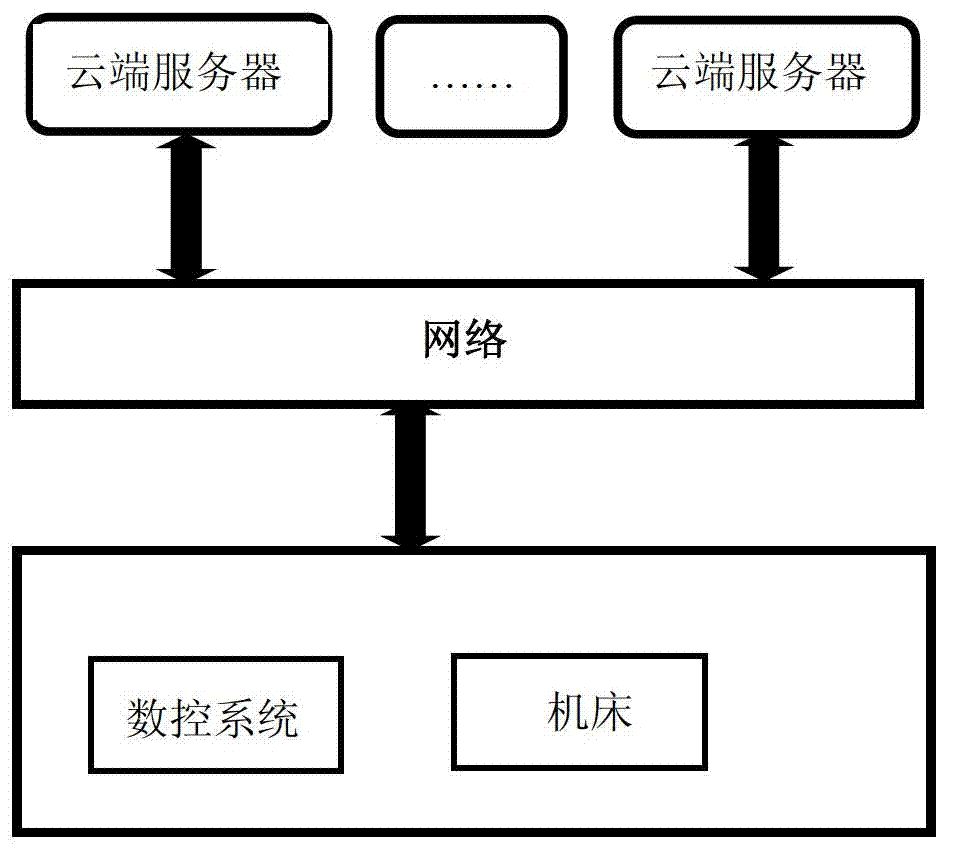

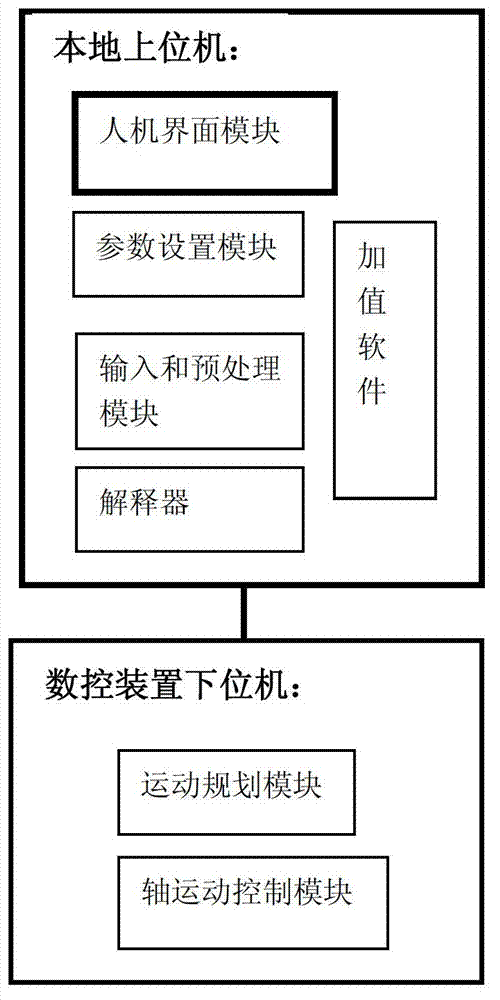

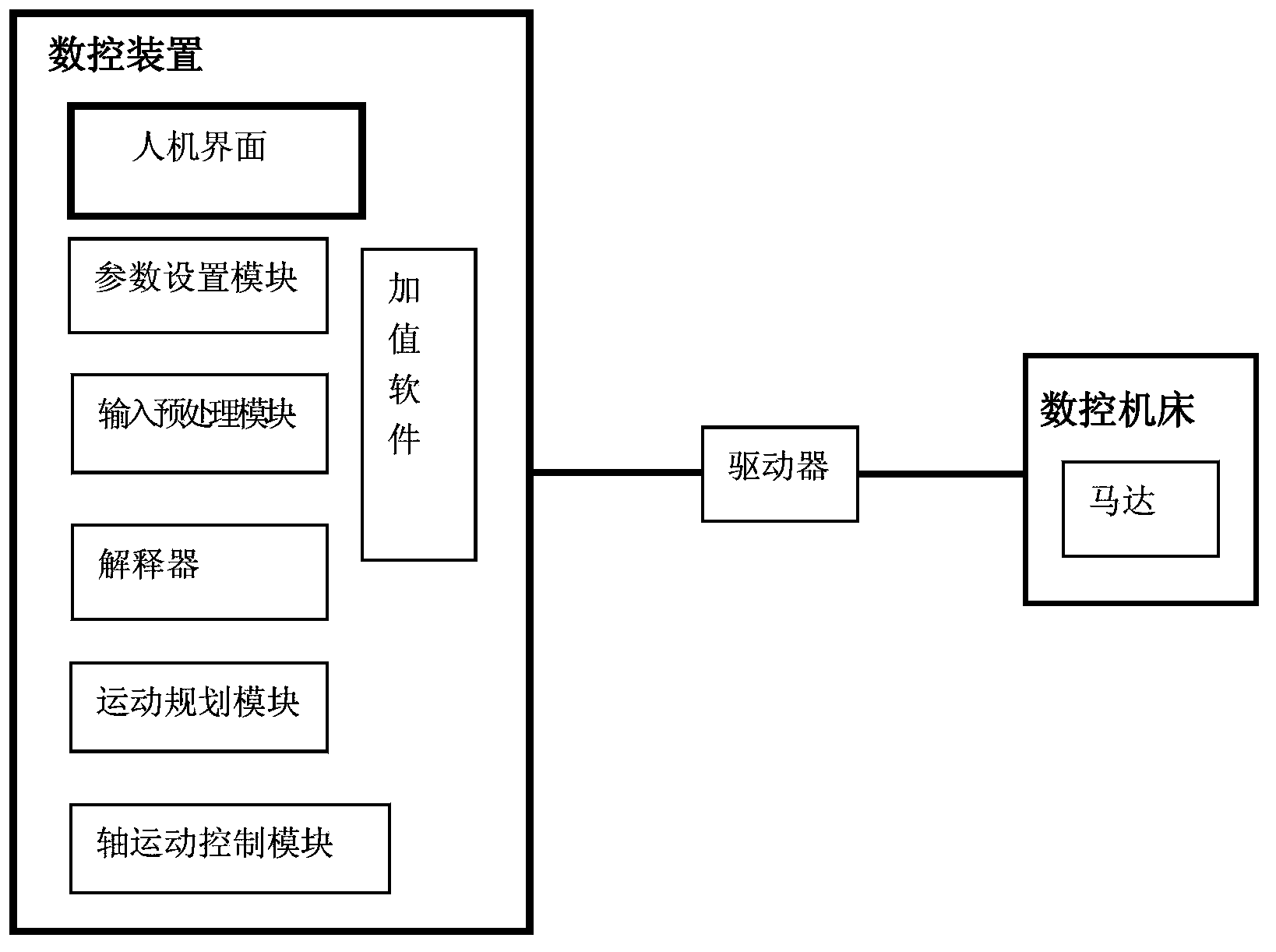

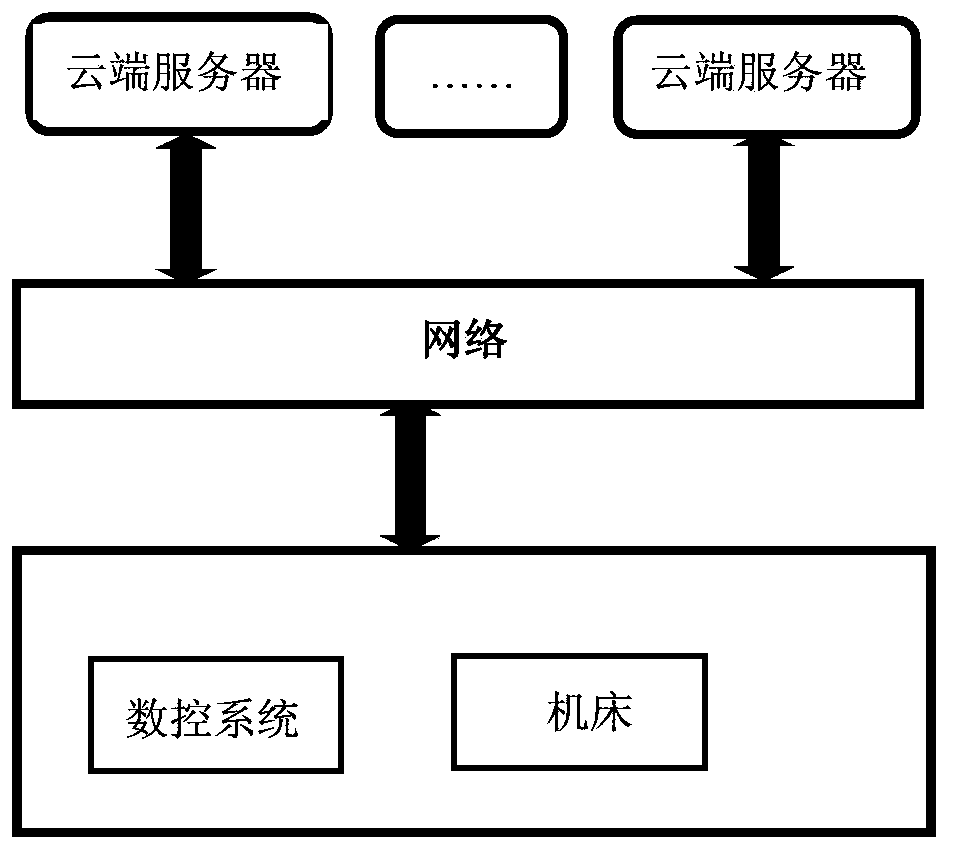

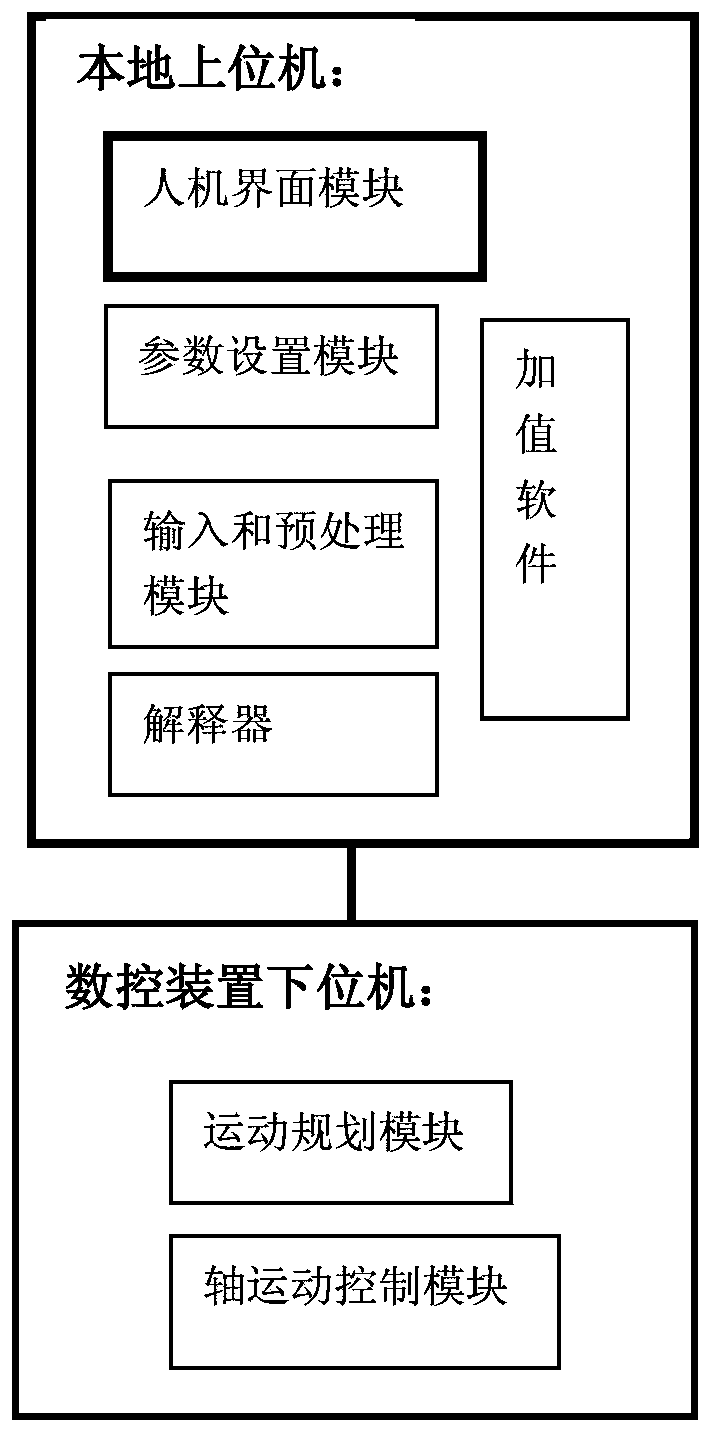

Method for realizing virtual machine tool model-based cloud terminal numerical control system and virtual machine tool model-based cloud terminal numerical control system

ActiveCN102736553ATake advantage of high-end featuresLow costTransmissionNumerical controlTerminal serverWorking environment

The invention discloses a method for realizing a virtual machine tool model-based cloud terminal numerical control system and the virtual machine tool model-based cloud terminal numerical control system. The method comprises the following steps of: establishing a corresponding virtual machine tool model module for each numerical control device lower computer, wherein the virtual machine tool model modules comprise basic parameters of machine tools and data systems; finishing human-computer interaction processes, inputting and preprocessing numerical control processing programs and decoding the numerical control processing programs by using cloud terminal servers, namely remote servers; and communicating the cloud terminal servers with the numerical control device lower computers through a network. The system comprises cloud terminal upper computers for preprocessing and decoding the numerical control processing programs, the numerical control device lower computers and at least one virtual machine tool model module for storing the basic parameters of the machine tools and the data systems, wherein the lower computers communicate with the cloud terminal upper computers and are used for controlling the speeds and the positions of the machine tools. By the method and the system, the cost of a production enterprise can be substantially reduced, and a comfortable working environment can be provided for machine tool operators at the same time.

Owner:WUHAN HUAZHONG NUMERICAL CONTROL +1

Virtual machine tool for representing operations of machining units of a real machine tool

ActiveCN101802734AChange sizeWear correctionProgramme controlComputer controlVirtual machiningTrue Case Status

The invention relates to a virtual machine tool for representing operations of machining units of the machine tool, especially operations during machining of a workpiece according to a CNC machining program package, using at least one first visualization unit, in the form of operations of virtual machining units. Said virtual machine tool comprises an operation control which has at least one first data processing unit that determines control commands for operations of the virtual machining units, using a control program processing CNC sets of the CNC machining program package, a visualizationcontrol comprising at least one second data processing unit that represents operations of the virtual machining units on the first visualization unit, using a visualization program and geometric configuration data of a stored machine model and the control commands determined by the operation control, and an operator control comprising a third data processing unit that operates the operation control, using an operator control program. The aim of the invention is to improve the virtual machine tool in such manner that the simulation of the machining of a virtual workpiece comes as close as possible to reality. The virtual machine tool according to the invention comprises a tool modeling system which allows the generation of tool configuration data for at least one virtual tool, using tool data and a tool model, and the supply thereof to the visualization program.

Owner:INDEX WERKE GMBH & CO KG HAHN & TESSKY

Emulation system

InactiveCN101187815ASuitable for requirementsSuitable for requirements in terms of ease of operationSimulator controlRecording and playback systemsProgram managementVirtual machining

The invention relates to an improvement simulation system, which is used on an actuation mode of a virtual processing unit of a virtual machine tool, and expresses action of the processing unit of the machine tool according to a CNC processing program complex by means of at least a first visualized unit. The invention comprises action control, and which comprises at least a first data handling unit. Action control command of the virtual processing unit and visualized control are established by controlling a procedure to handle a CNC block. And the invention comprises at least a second data handling unit, the determined control command is controlled by action according to layout data of a machine model which is stored, the action of the virtual processing unit is expressed on the first visualized unit on a visualized procedure, and the analog system is suggested to comprising operation control of a third data processing unit, the operation control is used for an operating procedure to control the action control, and the operating procedure has a program management function, at least a procedure of the CNC processing program complex is transferred to the action control for conveniently carrying out the program complex by the invention which is relative with workpieces.

Owner:INDEX WERKE GMBH & CO KG HAHN & TESSKY

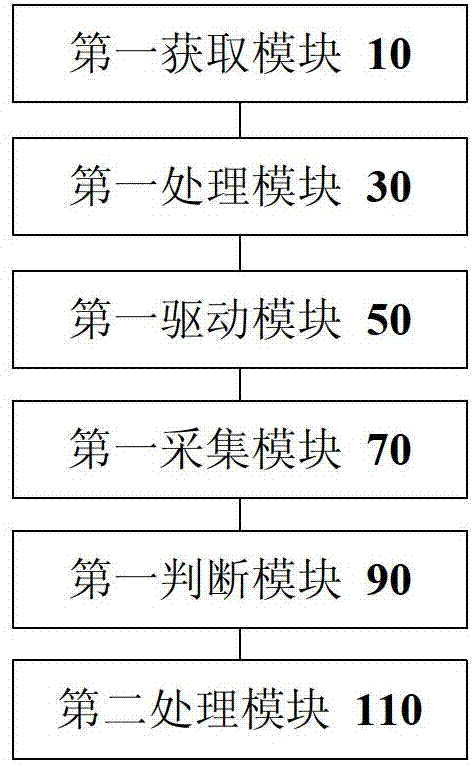

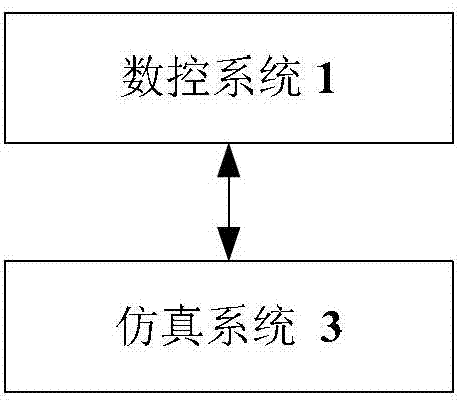

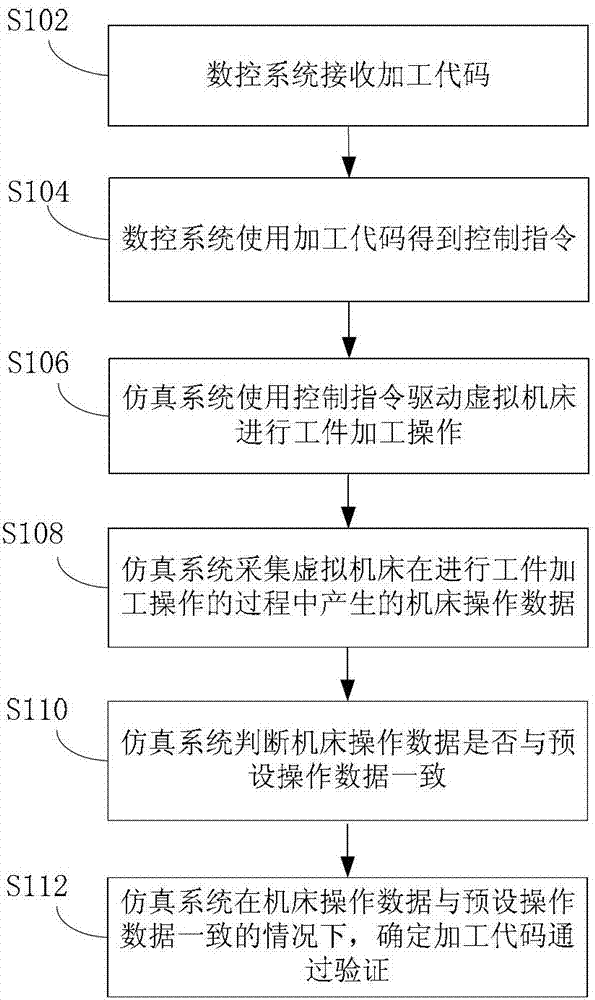

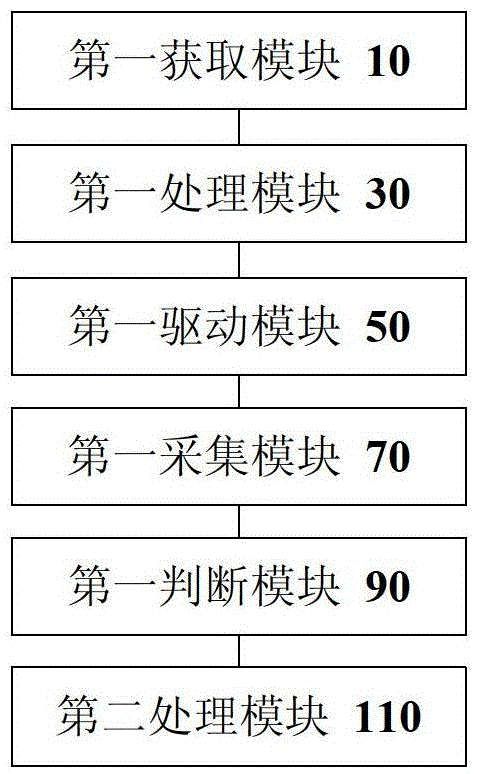

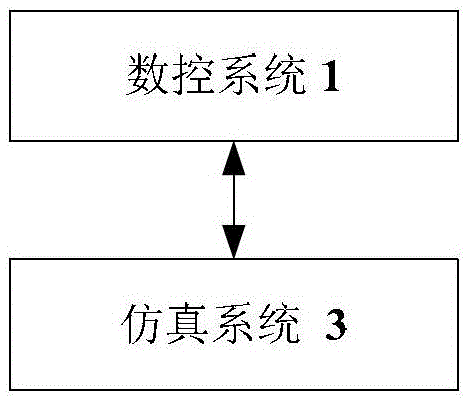

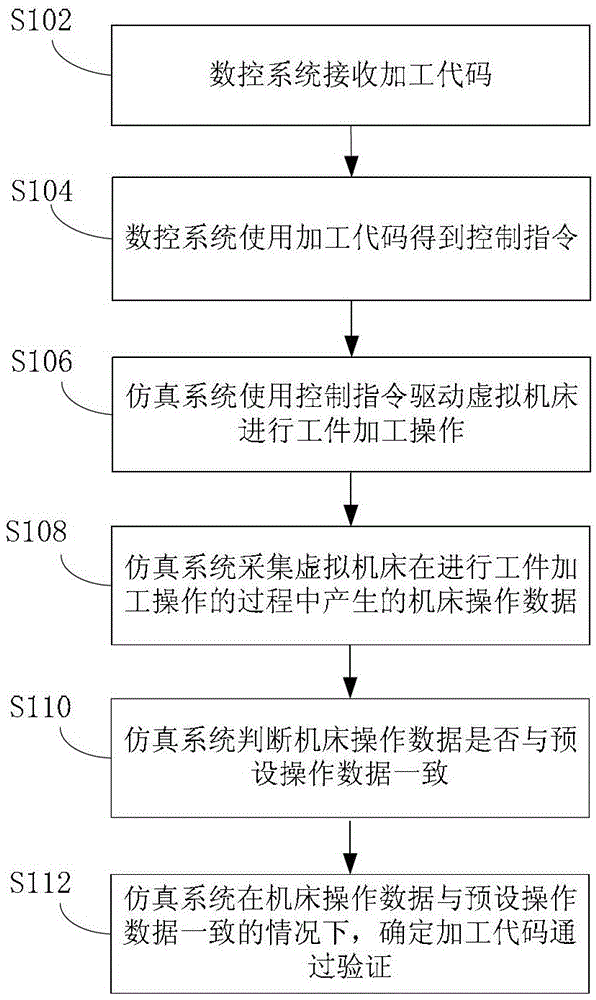

Verification method, device and system of machine tool machining codes

ActiveCN103048952AAccurate verificationAccurate analysisProgramme controlComputer controlValidation methodsVirtual machine tool

The invention discloses a verification method, device and system of machine tool machining codes. The method comprises the following steps that: a numerical control system receives the machining codes; the numerical control system uses the machining codes to obtain control instructions; a simulation system uses the control instructions to drive a virtual machine tool to carry out workpiece machining operation, wherein the virtual machine tool is a previously simulated machine tool model; the simulation system acquires machine tool operation data generated in the workpiece machining operation process of the virtual machine tool; the simulation system judges whether the machine tool operation data are accordant with preset operation data, wherein the preset operation data are prestored operation data, corresponding to the machining codes, of the machine tool; and the simulation system confirms that the machining codes are qualified in verification under the condition that the machine tool operation data are accordant with the preset operation data. The effect of accurately analyzing the machining codes so as to accurately verify the machining codes is achieved.

Owner:CAXA TECH

Simulation system

ActiveUS7684890B2Improve operational convenienceEasy to handleProgramme controlSpecial data processing applicationsMain processing unitProgram management

In order to improve a simulation system for representing actions of machining units of a machine tool, in particular actions in the machining of a workpiece, in accordance with a CNC machining program complex by means of at least one first visualization unit in the form of actions of virtual machining units of a virtual machine tool, comprising an action control, which has at least one first data processing unit, which establishes control commands for actions of the virtual machining units by a control program processing CNC blocks of the CNC machining program complex, and a visualization control, which has at least one second data processing unit, which represents actions of the virtual machining units on the first visualization unit by a visualization program on the basis of configuration data of a stored machine model and the control commands determined by the action control, in such a way that it can be operated more easily, it is proposed that the simulation system comprises an operating control with a third data processing unit, which operates the action control by an operating program, and that the operating program has a program management function, which transfers at least program parts of the CNC machining program complex in a workpiece-related manner from said CNC machining program complex stored in a memory of the third data processing unit to the action control for executing said program complex.

Owner:INDEX WERKE GMBH & CO KG HAHN & TESSKY

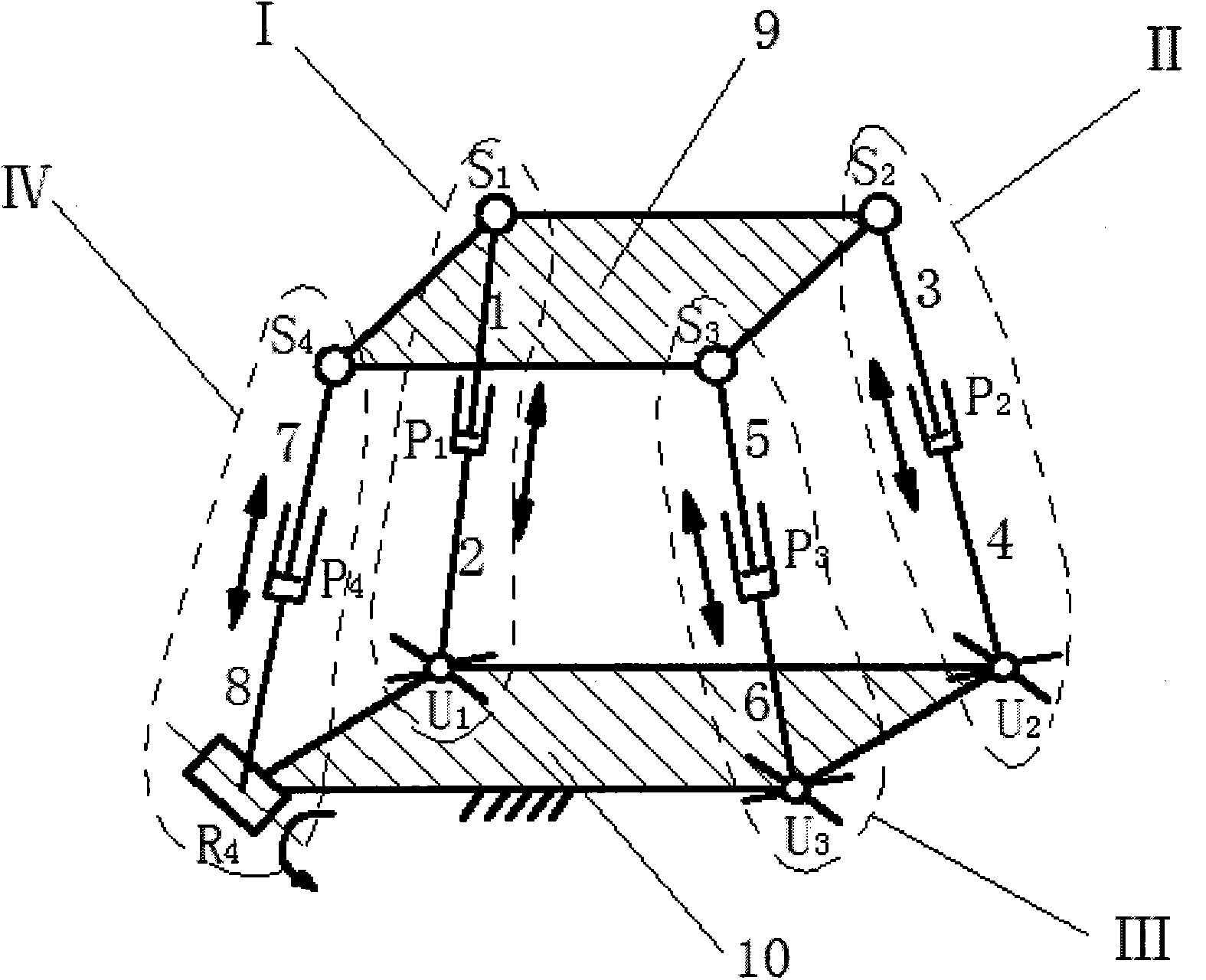

Four freedom degree parallel mechanism with series input branch chains

InactiveCN104102170APartially decoupledPartially decoupled implementationNumerical controlKinematicsEngineering

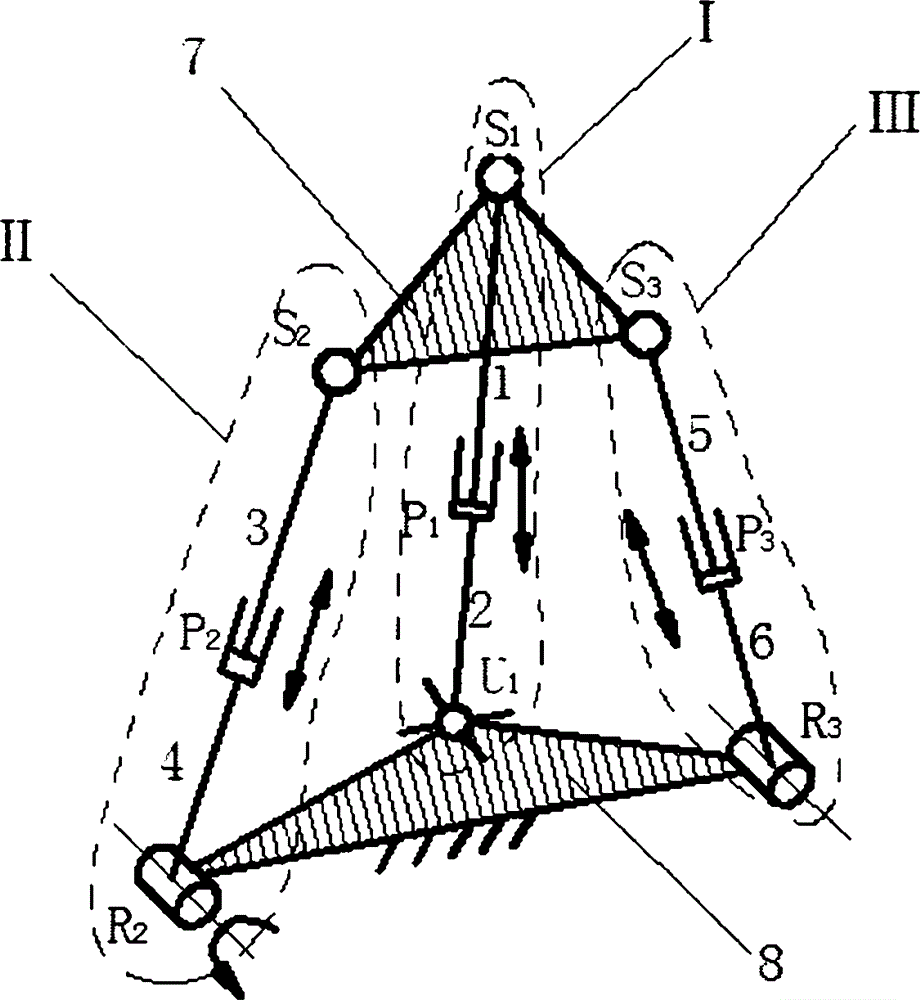

The invention provides a four freedom degree parallel mechanism with series input branch chains. The mechanism is composed of a dynamic platform, a static platform and three branch chains. The first branch chain is composed of a hooke hinge, a moving pair and a spherical pair, wherein the hooke hinge, the moving pair and the spherical pair are connected in series. The second branch chain is composed of a rotating pair, a moving pair and a spherical pair, wherein the rotating pair, the moving pair and the spherical pair are connected in series. The structure of the third branch chain and the structure of the second branch chain are completely same. According to the configuration mode of the three branch chains on two platforms, by driving the moving pairs in the three branch chains and the rotating pair in the second branch chain, two translation and two rotating output of the dynamic platform is controlled. According to the mechanism, undesired motion output is constant; partial control decoupling is realized between motion output and input; kinematics normal solution is easy; the mechanism has the advantages of simple structure, good rigidity and the like; and the mechanism can be used as a reconfigurable actuator of a virtual machine tool and a robot.

Owner:TIANJIN POLYTECHNIC UNIV

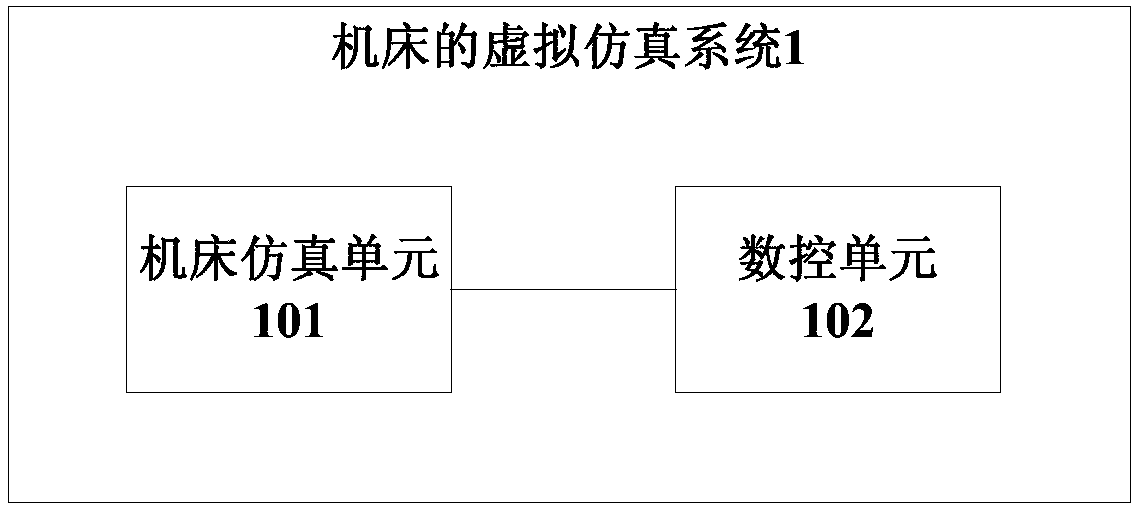

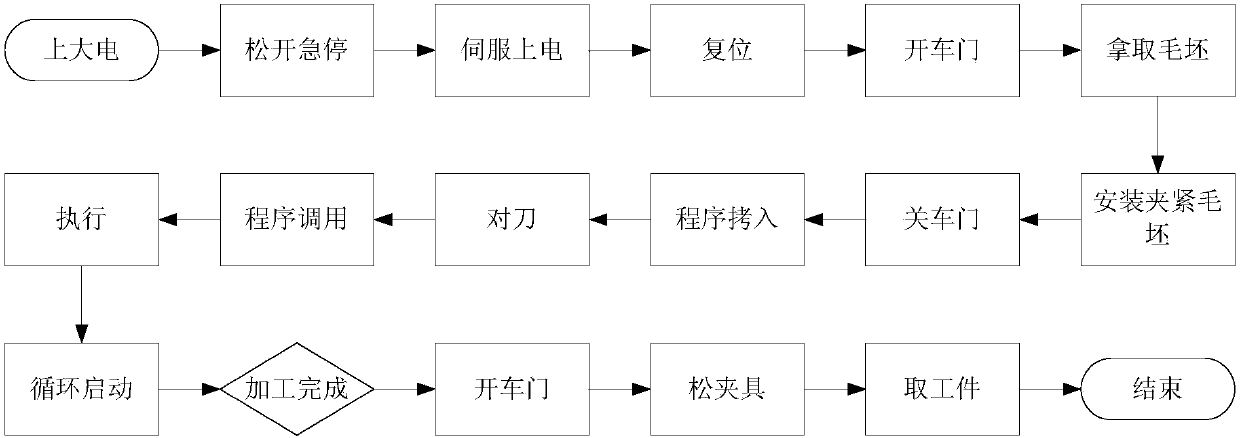

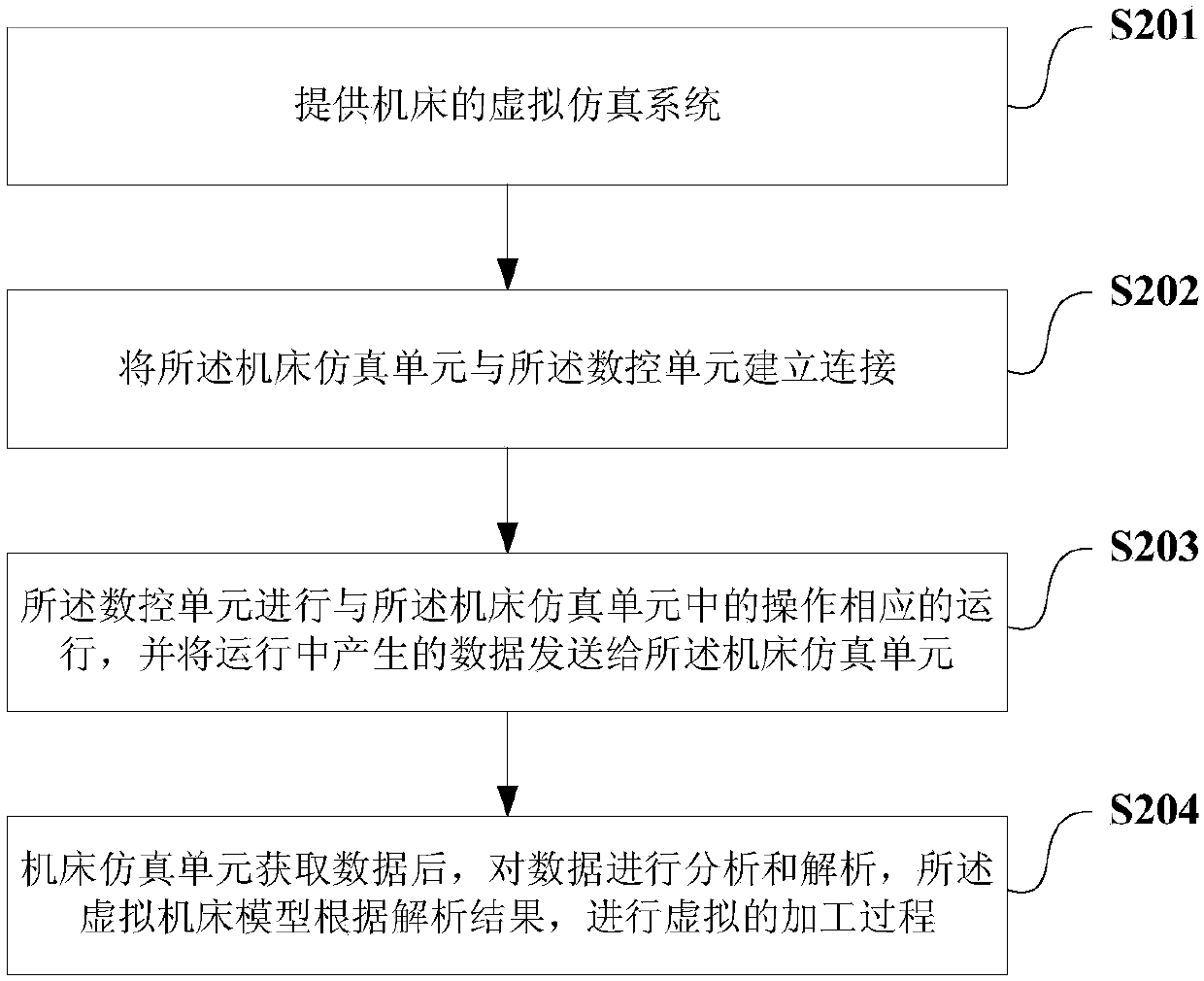

Virtual simulation system for machine tool, and virtual manufacturing method and manufacturing apparatus

InactiveCN107944067AGuarantee personal safetyIncrease costInput/output for user-computer interactionConfiguration CADNumerical controlVirtual work

The invention provides a virtual simulation system for a machine tool, and a virtual manufacturing method and manufacturing apparatus. The virtual simulation system mainly comprises a machine tool simulation unit used for providing a virtual machine tool model and obtaining machine tool operation and user operation on the virtual machine tool model, and a numerical control unit used for performingcorresponding operation according to the machine tool operation and the user operation and feeding back an operation condition to the machine tool simulation unit in real time. Moreover, the virtualmachine tool model performs corresponding virtual work in real time according to the operation condition fed back by the numerical control unit. Through analog simulation of the machine tool, a working process of the machine tool is really displayed and the personal safety of machine tool operators is effectively ensured.

Owner:SYMG SHANGHAI INTELLIGENCE SYST CO LTD

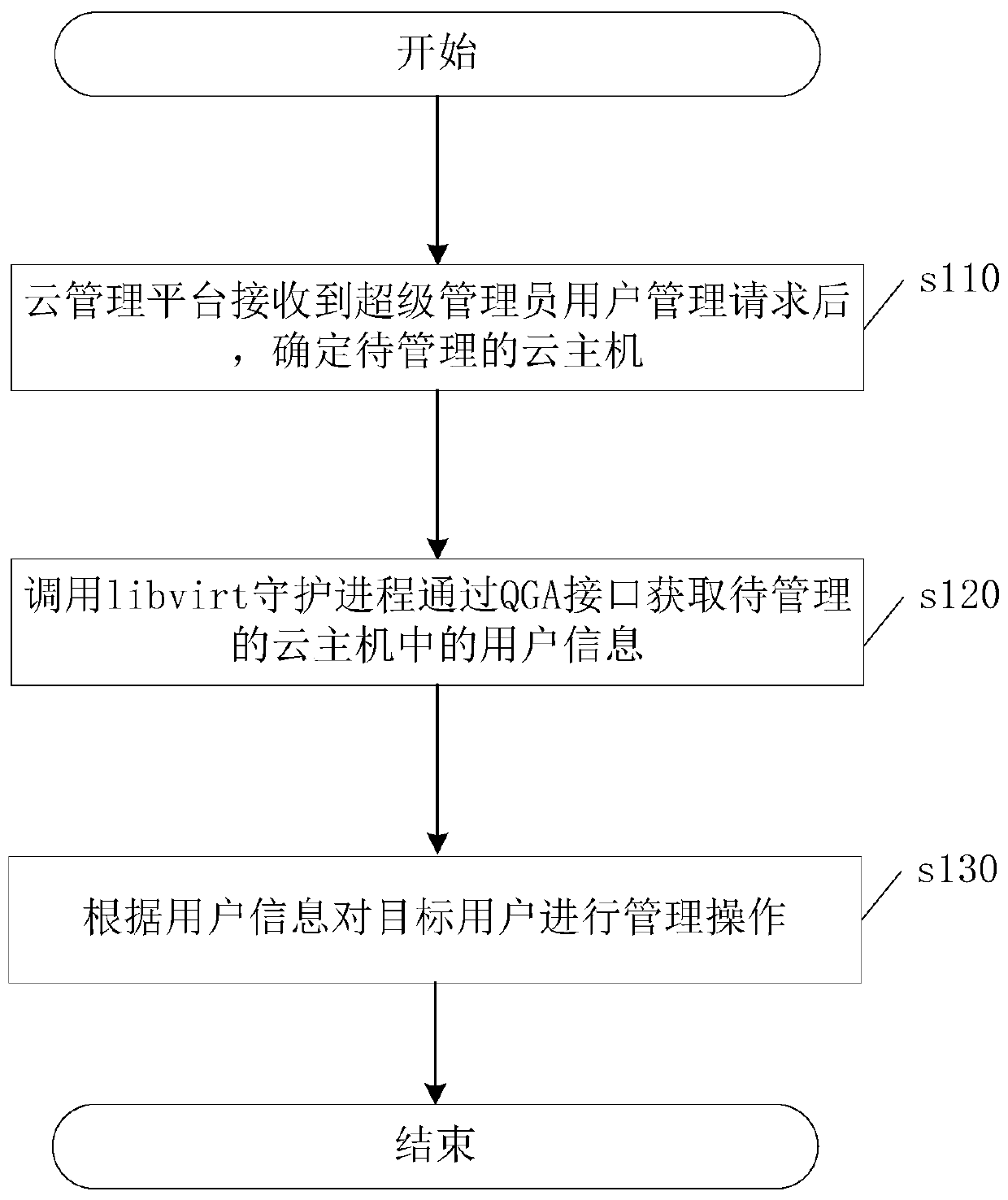

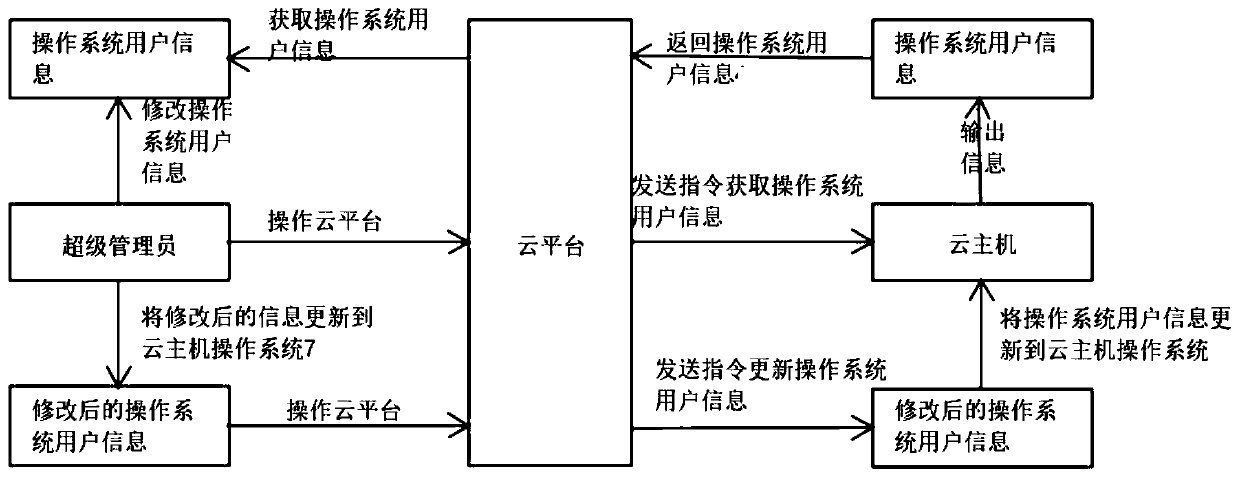

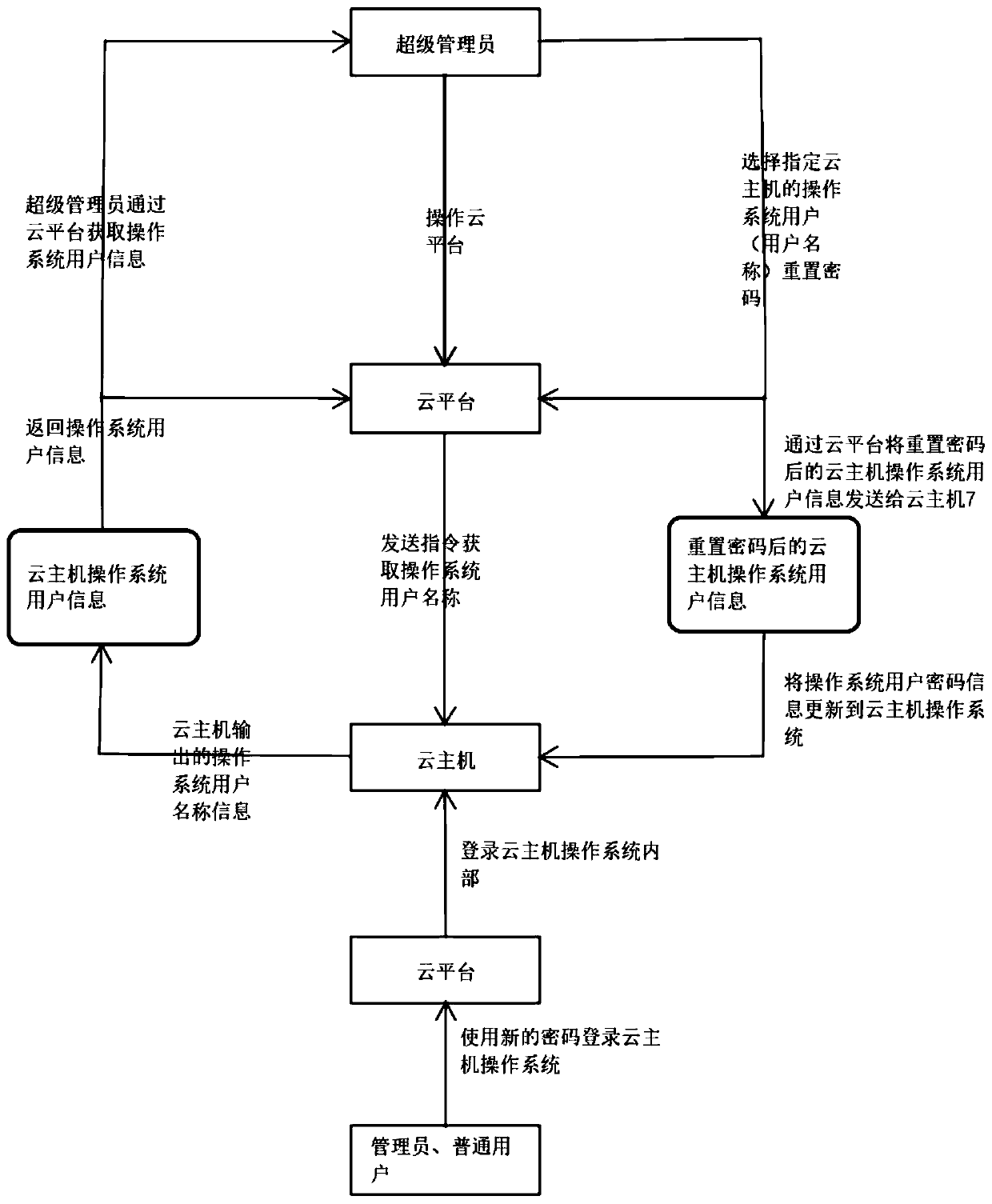

Cloud host operating system user management method, device and apparatus and storage medium

InactiveCN111258721AImplement management operationsAvoid loginDigital data protectionSoftware simulation/interpretation/emulationSoftware engineeringUser management

The invention discloses a cloud host operating system user management method, which comprises the steps of starting a libvirt daemon process through a cloud management platform server, and installinga QGA virtual machine tool in a cloud host to realize communication between the daemon process and the interior of a cloud host system; achieving communication between a host machine and a cloud hostbased on QGA; enabling a super administrator to send an instruction to the cloud host through the cloud platform so that the user information in each to-be-managed cloud host can be obtained on the cloud management platform through the QGA interface. The cloud hosts are not required to be logged into the cloud hosts one by one to realize user management, login operation of the cloud hosts is avoided, unified management operation of users of cloud host operating systems on the cloud platform is realized, management steps are simplified, and management efficiency is improved. The invention further provides a cloud host operating system user management device and equipment and a readable storage medium, which have the above beneficial effects.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

Virtual machine and actual electrical machining simulation method for five-axle number control machine tool

InactiveCN101592920ARealize visualizationQuick responseSimulator controlSpecial data processing applicationsNumerical controlGraphics

The invention discloses a virtual machine and actual electrical machining simulation method for a five-axle number control machine tool, which is used for simulating the machining process of the five-axle number control machine tool. The method comprises the following steps: modeling the five-axle number control machine tool, i.e. performing simulation modeling and graphic displaying to the machining process of the five-axle number control machine tool; virtual machine tool motion and machining simulation, i.e. respectively simulating the motion and the machining of the five-axle number control machine tool; and data acquisition and transmission, i.e. detecting the variation of data quantity in a virtual environment through a data sensor and then a virtual mechanism is driven to move. The invention realizes the visualization inside a three-dimensional entity; a local refreshing technology is adopted on the graphic display aspect during the simulation of the machining process, so the simulation effect and the graphic display efficiency are ensured; and the multi-threading operational mode increases the response speed of the application program. The invention can greatly enhance the machining simulation precision of the five-axle number control machine tool.

Owner:SHANGHAI ELECTRICGROUP CORP

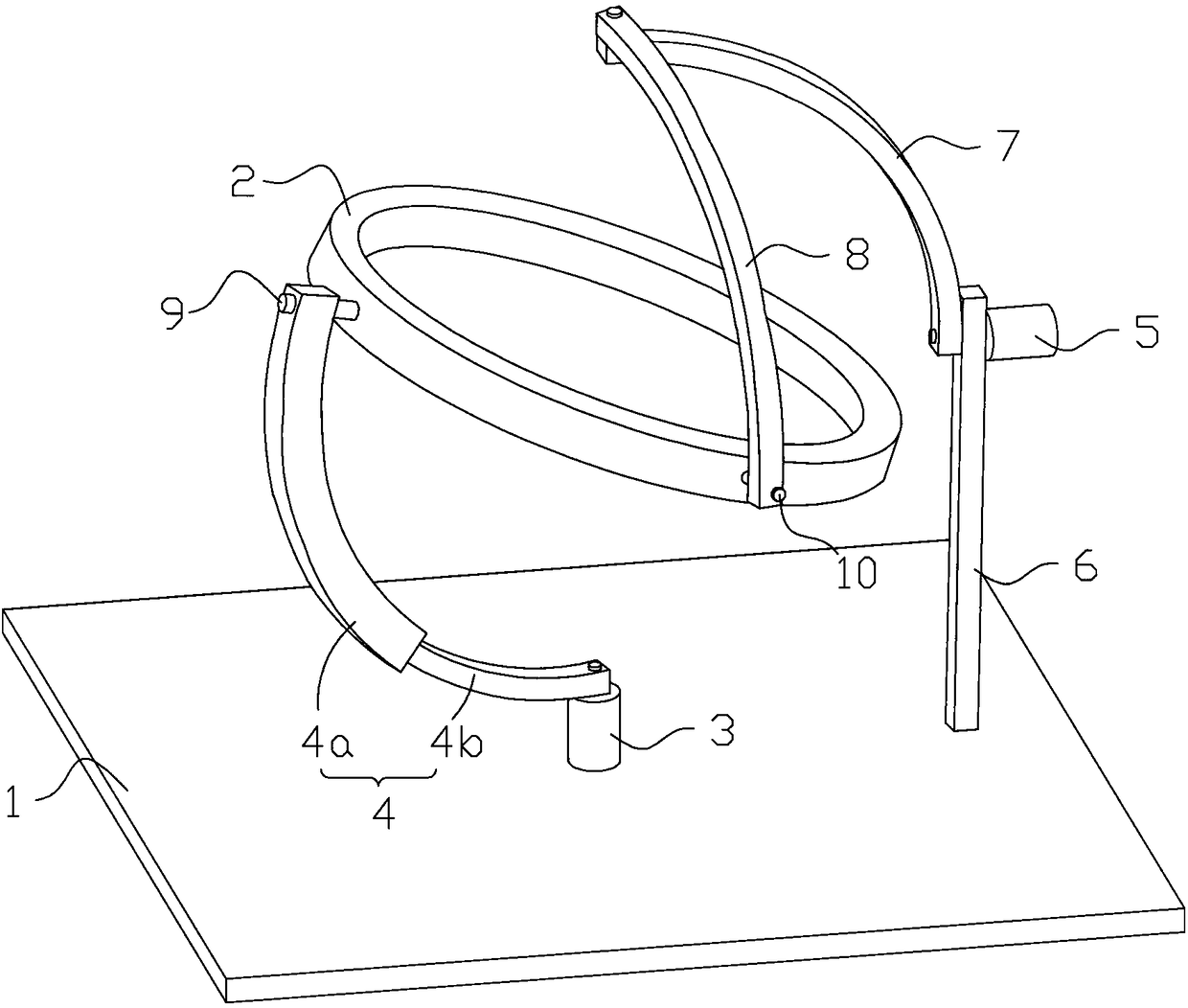

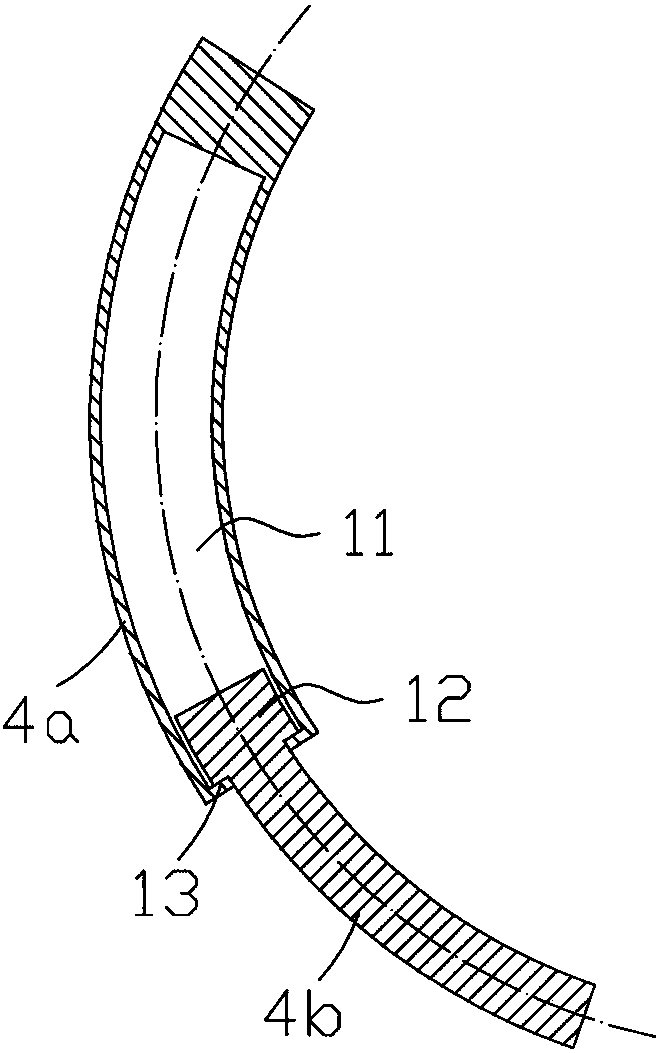

Partially-decoupled two-freedom-degree parallel mechanism

PendingCN108356802AGuaranteed uptimeSimple structureProgramme-controlled manipulatorAviationEngineering

The invention discloses a partially-decoupled two-freedom-degree parallel mechanism. The partially-decoupled two-freedom-degree parallel mechanism comprises a stationary platform, a movable platform,a first moving branch chain and a second moving branch chain; the first moving branch chain comprises a first revolute pair; the stationary platform is rotationally connected with one end of a first arc-shaped connecting rod through the first revolute pair; the second moving branch chain comprises a second revolute pair; the stationary platform is provided with a bracket; the bracket is rotationally connected with one end of a second arc-shaped connecting rod through the second revolute pair; the other end of the second arc-shaped connecting rod is rotationally connected with one end of a third arc-shaped connecting rod; a first pin shaft and a second pin shaft which are arranged in a manner of forming an included angle of 90 degrees with each other are installed at the side surface of themovable platform; the other end of the first arc-shaped connecting rod is rotationally connected with the first pin shaft; and the other end of the third arc-shaped connecting rod is rotationally connected with the second pin shaft. The partially-decoupled two-freedom-degree parallel mechanism disclosed by the invention is simple in structure and high in flexibility, runs stably, realizes partialdecoupling of two rotation freedom degrees and can be applied to the fields of virtual machine tools, aviation simulation equipment, industrial robots, medical surgical equipment and the like.

Owner:HUBEI POLYTECHNIC UNIV

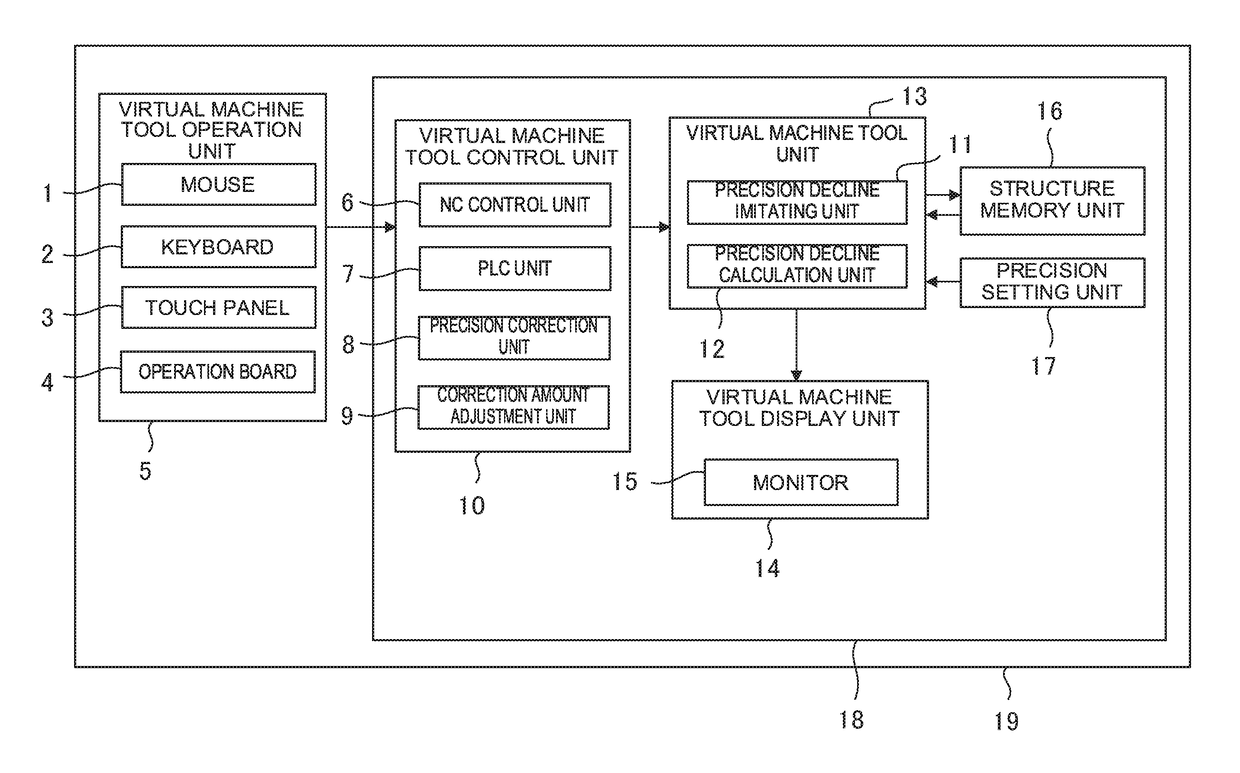

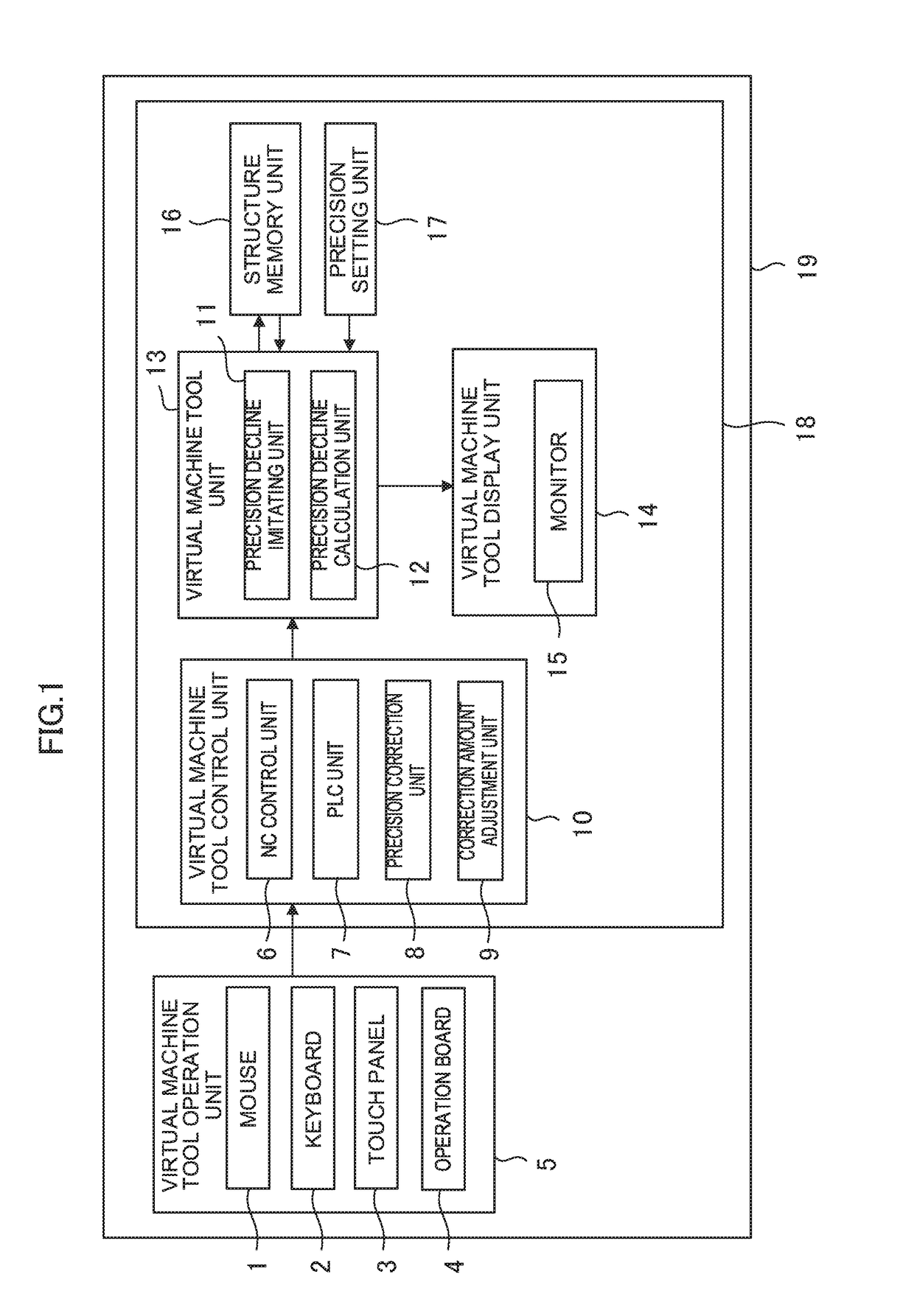

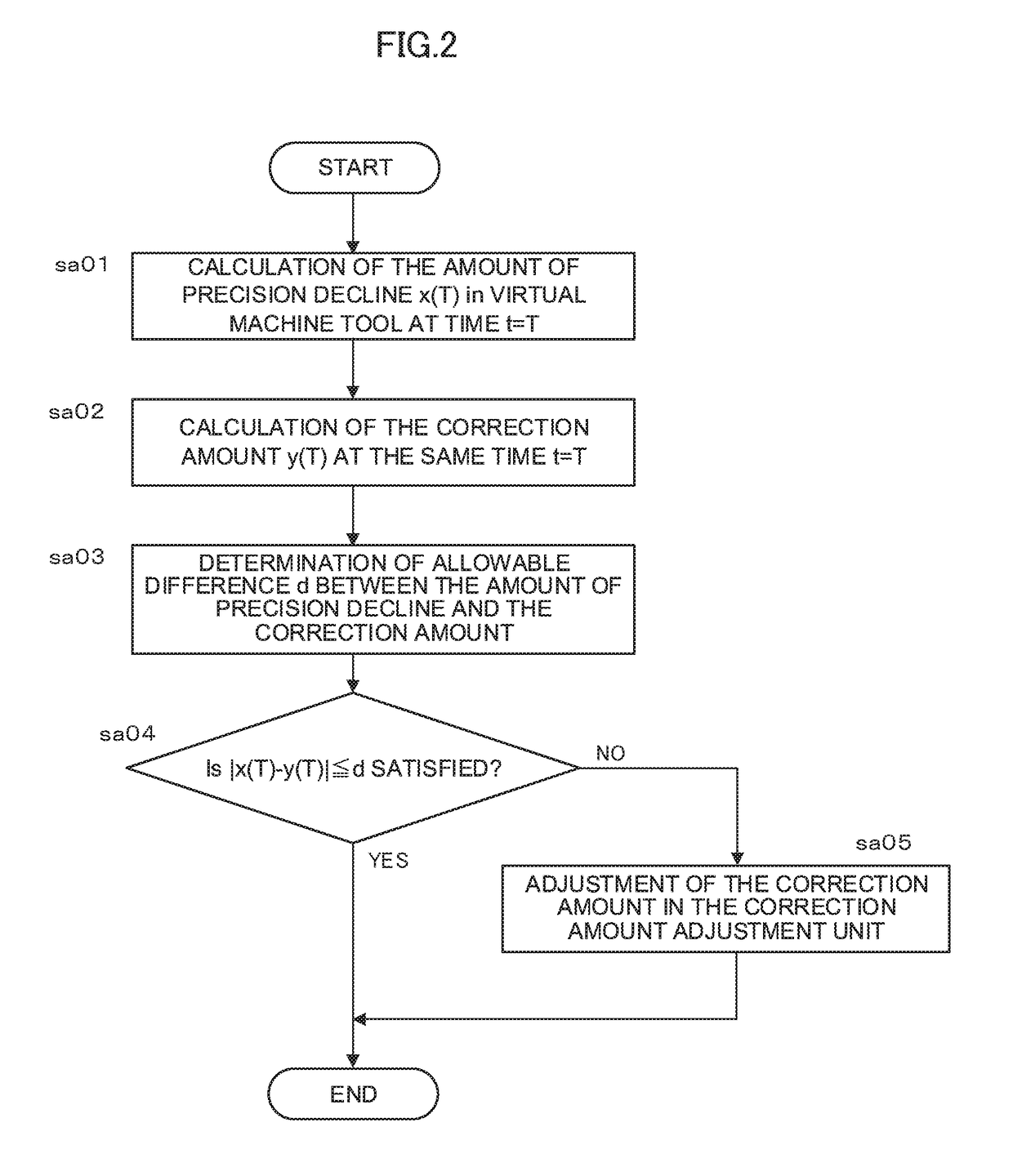

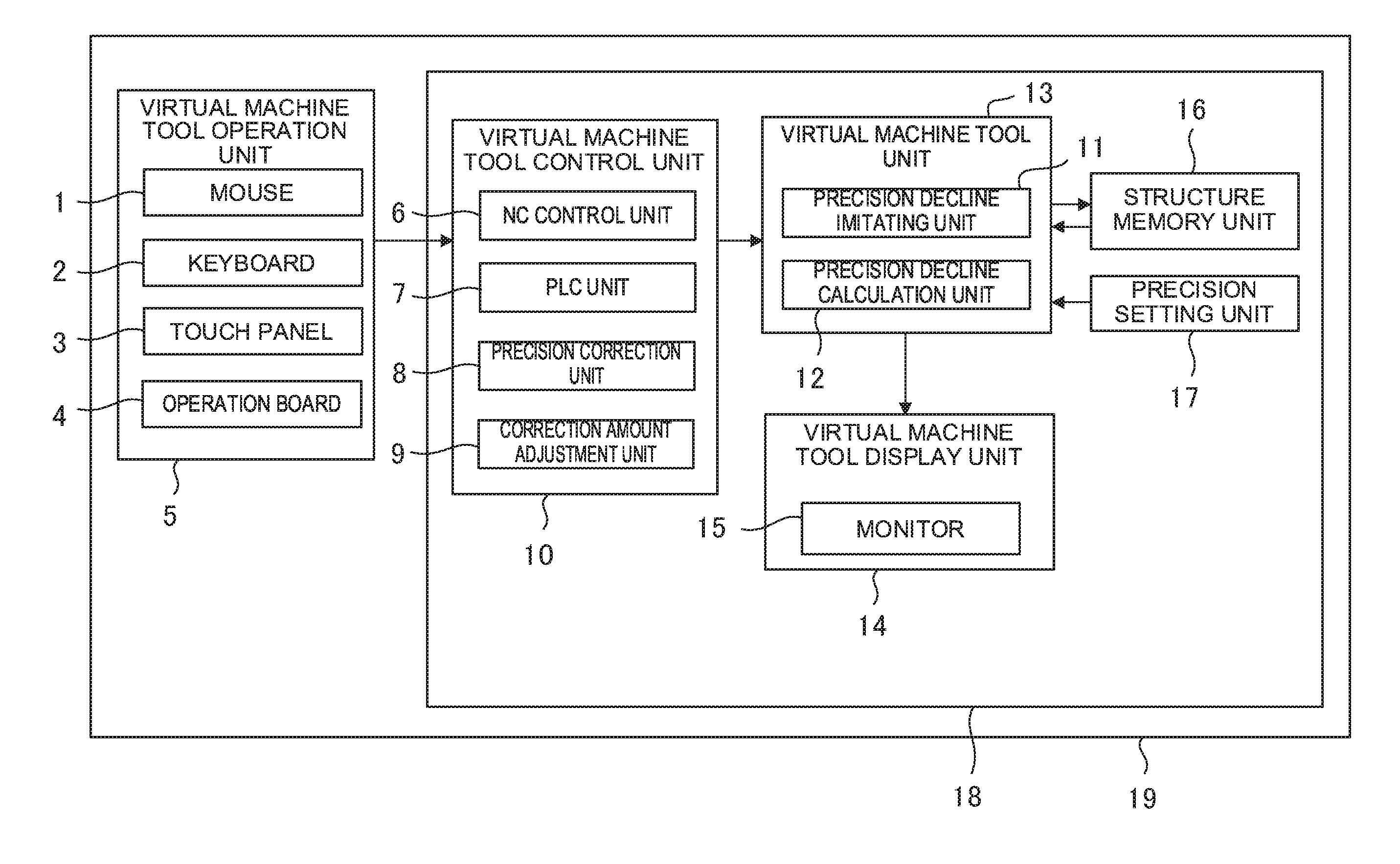

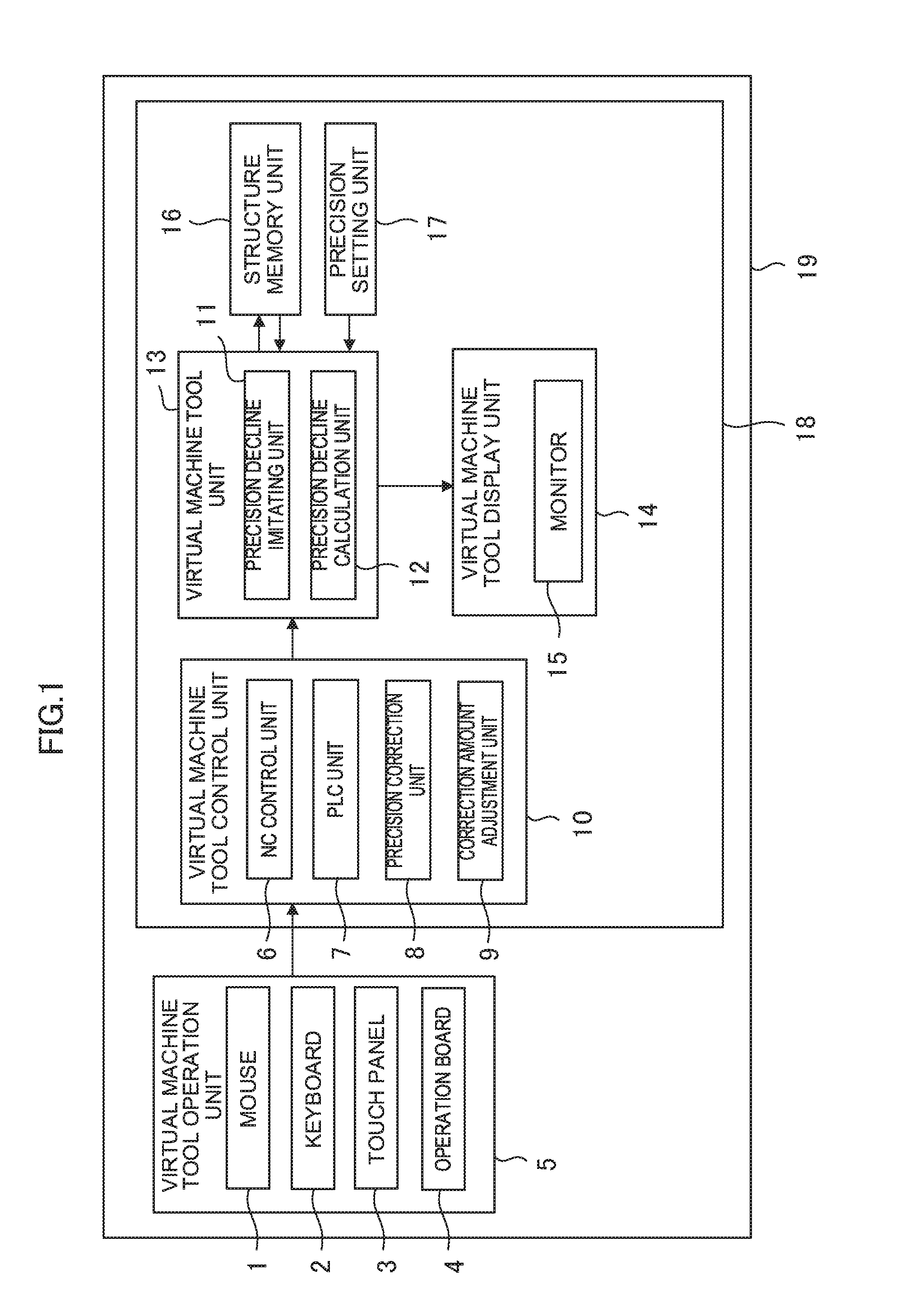

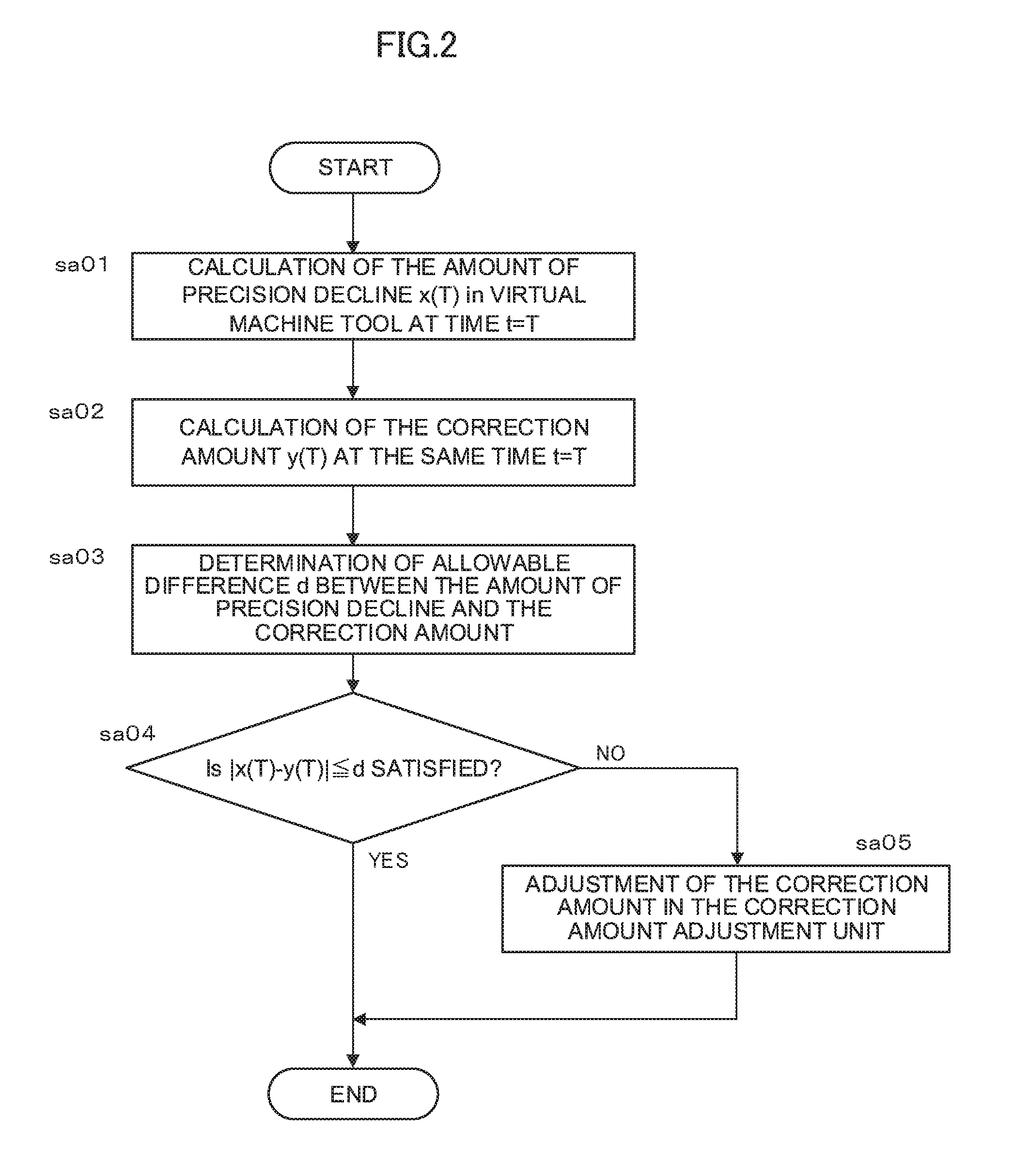

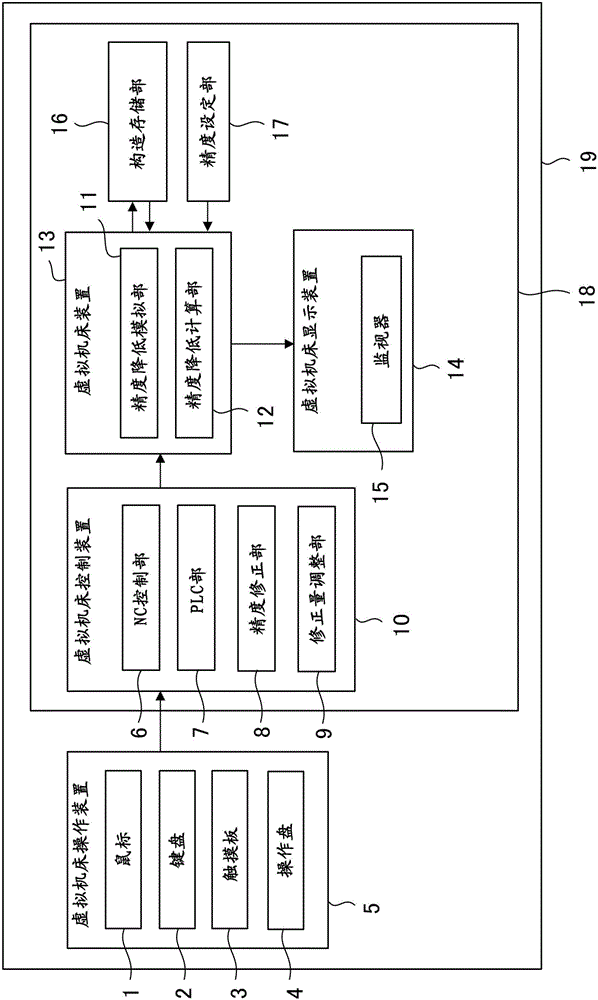

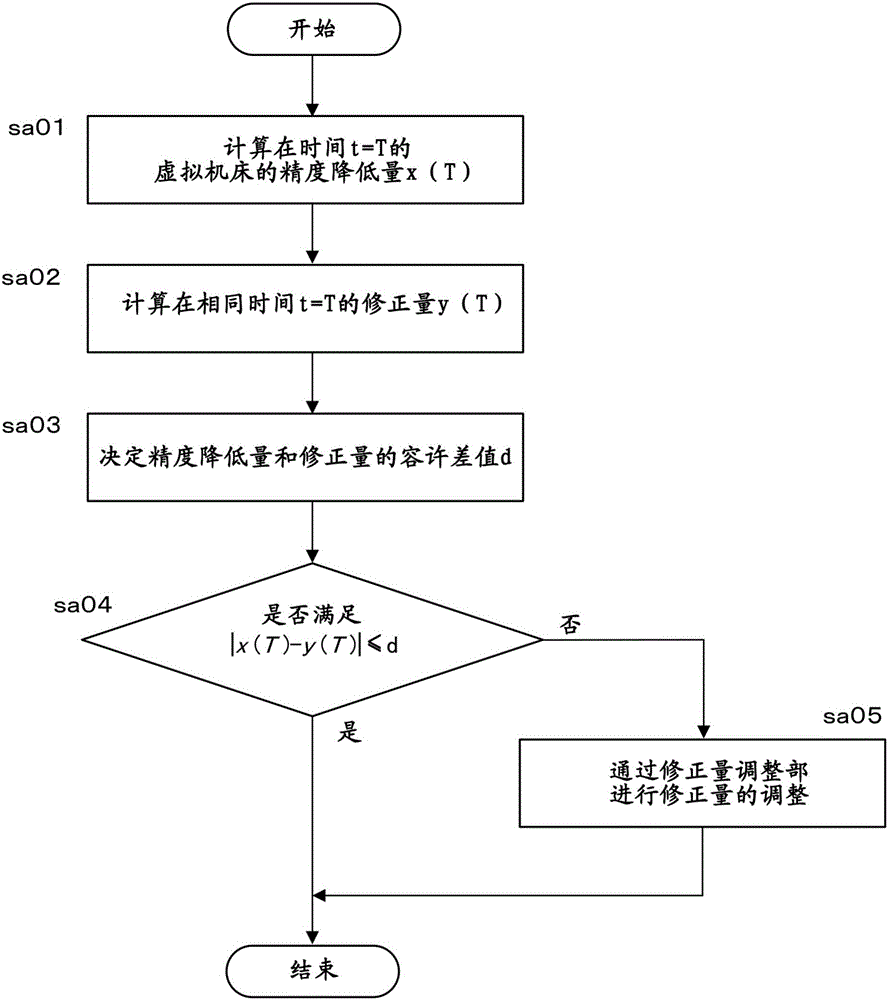

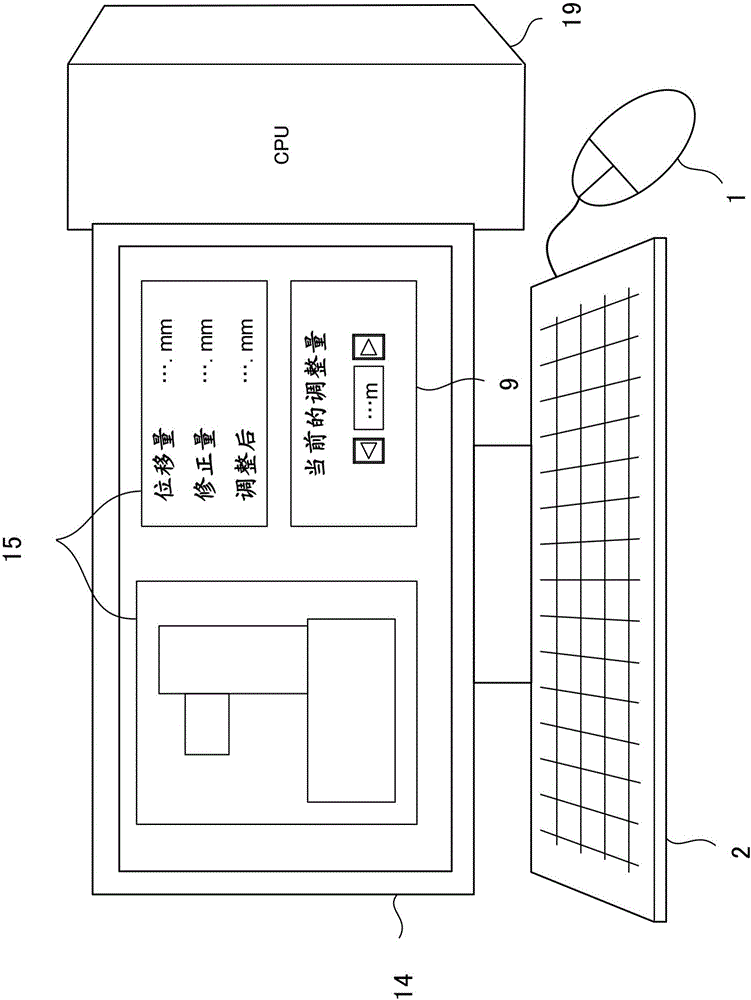

Thermal displacement correction training unit for machine tool

A thermal displacement correction training unit has a virtual machine tool, a virtual machine tool control unit and a virtual machine tool display unit. The virtual machine tool has a precision decline imitating unit for imitating the process precision decline caused by the heat during operation in the virtual machine tool unit, and a precision decline calculation unit for finding the amount of precision decline that represents the process precision decline in the process machine unit imitated by the process precision imitating unit. The virtual machine tool control unit has a precision correction unit for finding the correction amount by which the processing point is corrected in response to thermal displacement, and a correction amount adjustment unit for adjusting the correction amount found by the precision correction unit. The virtual machine tool display unit displays the amount of precision decline and the correction amount.

Owner:FANUC LTD

Two-translation-and-three-turning parallel mechanism used for virtual machine tool

InactiveCN104227434APartially decoupledPartially decoupled implementationLarge fixed membersKinematicsParallel computing

The invention provides a two-translation-and-three-turning parallel mechanism used for virtual machine tools. The parallel mechanism is composed of a motion platform, a fixed platform and four branch chains, a hooke joint, a sliding pair and a spherical pair are in serial connection to form a first branch chain, and a second branch chain and a third branch chain have a same structure with the first branch chain. A revolute pair, a sliding pair and a spherical pair are in serial connection to form a fourth branch chain. Configuration method of the four branch chains between two platforms is that two-translation-and-three-turning output of the motion platform can be controlled by driving the sliding pairs in the four branch chains and the revolute pair in the fourth branch chain. The two-translation-and-three-turning parallel mechanism regards unexpected movement output as a constant, partial control decoupling can be achieved through movement output-input, kinematics positive solution is easier, and therefore, the two-translation-and-three-turning parallel mechanism has the advantages of simple structure and fine rigidity and the like and can serve as a reconfigurable executing mechanism of the virtual machine tools and robots.

Owner:TIANJIN POLYTECHNIC UNIV

Thermal displacement correction training unit for machine tool

A thermal displacement correction training unit has a virtual machine tool, a virtual machine tool control unit and a virtual machine tool display unit. The virtual machine tool has a precision decline imitating unit for imitating the process precision decline caused by the heat during operation in the virtual machine tool unit, and a precision decline calculation unit for finding the amount of precision decline that represents the process precision decline in the process machine unit imitated by the process precision imitating unit. The virtual machine tool control unit has a precision correction unit for finding the correction amount by which the processing point is corrected in response to thermal displacement, and a correction amount adjustment unit for adjusting the correction amount found by the precision correction unit. The virtual machine tool display unit displays the amount of precision decline and the correction amount.

Owner:FANUC LTD

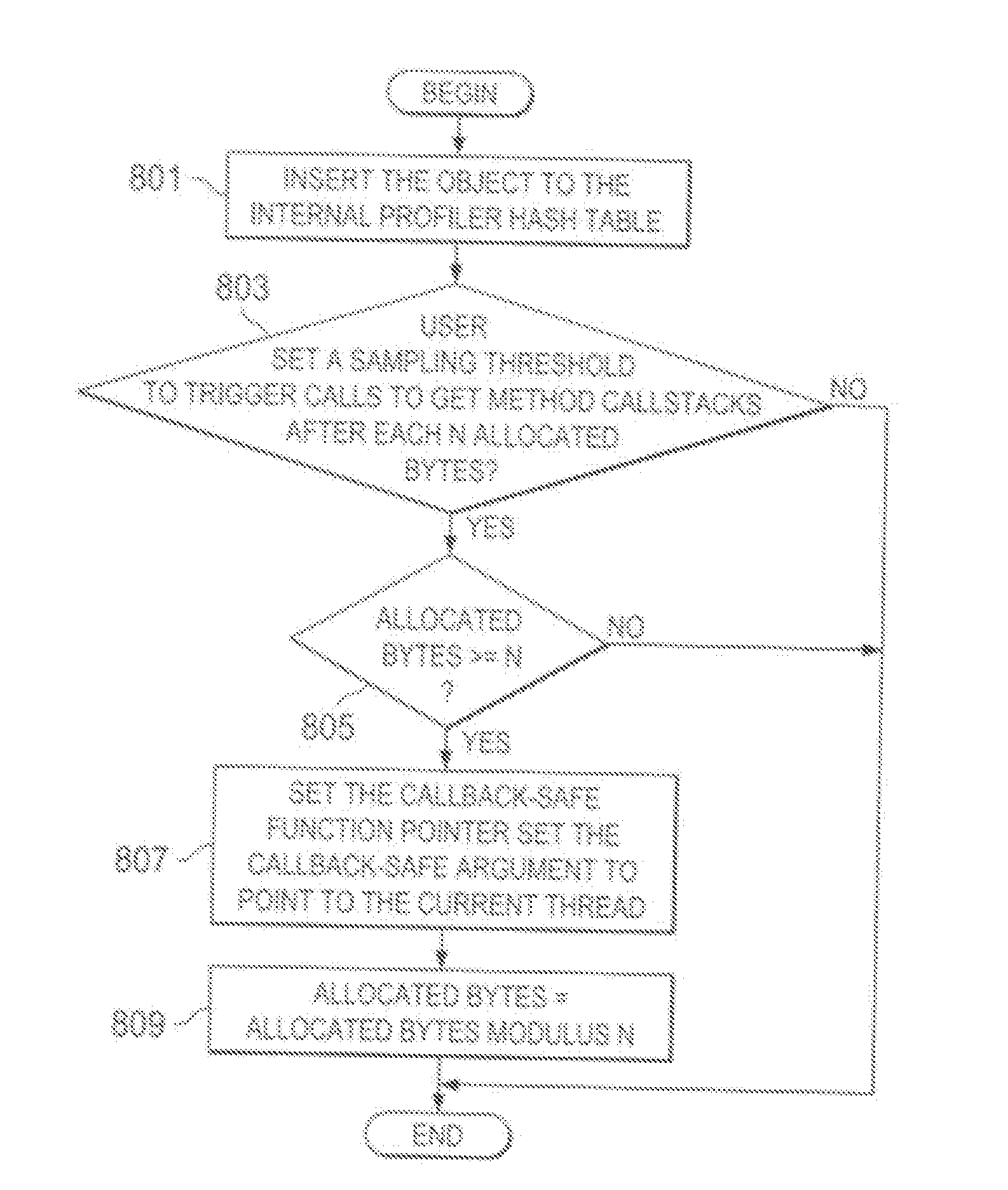

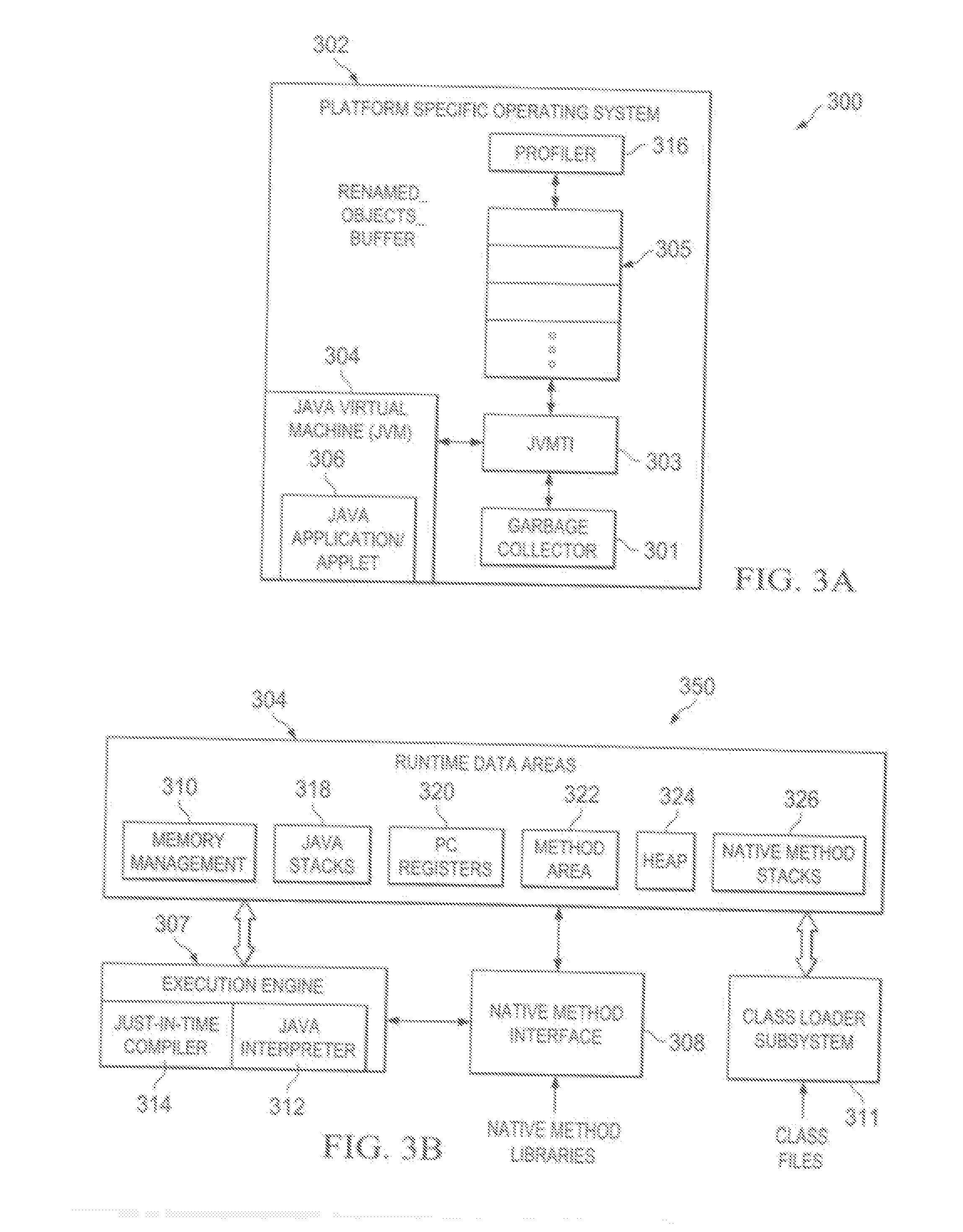

Virtual Machine Tool Interface For Tracking Objects

InactiveUS20120167043A1Error detection/correctionSpecific program execution arrangementsData processing systemWaste collection

Owner:INT BUSINESS MASCH CORP

Novel method for simulating machining of five-axis numerical control machine tool

The invention discloses a novel method for simulating a machining process of a five-axis numerical control machine tool. The novel method comprises the following steps of: modeling the five-axis numerical control machine tool, namely performing simulation modeling and graphical display on the machining process of the five-axis numerical control machine tool; simulating the motion and the machining of a virtual machine tool, namely simulating the motion and the machining of the five-axis numerical control machine tool respectively; and acquiring and transmitting data, namely detecting the change of the data quantity in a virtual environment through a data sensor and driving the motion of a virtual mechanism. According to the method disclosed by the invention, the interior of a three-dimensional entity is visible; during simulation of the machining process, the graphical display aspect is performed by adopting a partial updating technology, so that the simulation effect and the graphical display efficiency are guaranteed; by adopting a multi-thread working mode, the response of an application program is improved; and According to the novel method, the precision of the simulation for the machining process of the five-axis numerical control machine tool can be improved greatly.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

Thermal Displacement Correction Training Unit For Machine Tool

ActiveCN106157721AProgramme controlCosmonautic condition simulationsComputer scienceThermal displacement

A thermal displacement correction training unit for a machine tool has a virtual machine tool, a virtual machine tool control unit and a virtual machine tool display unit. The virtual machine tool has a precision decline imitating unit for imitating the process precision decline caused by the heat during operation in the virtual machine tool unit, and a precision decline calculation unit for finding the amount of precision decline that represents the process precision decline in the process machine unit imitated by the process precision imitating unit. The virtual machine tool control unit has a precision correction unit for finding the correction amount by which the processing point is corrected in response to thermal displacement, and a correction amount adjustment unit for adjusting the correction amount found by the precision correction unit. The virtual machine tool display unit displays the amount of precision decline calculated by the precision decline calculation unit of the virtual machine tool and the correction amount adjusted by the correction amount adjustment unit.

Owner:FANUC LTD

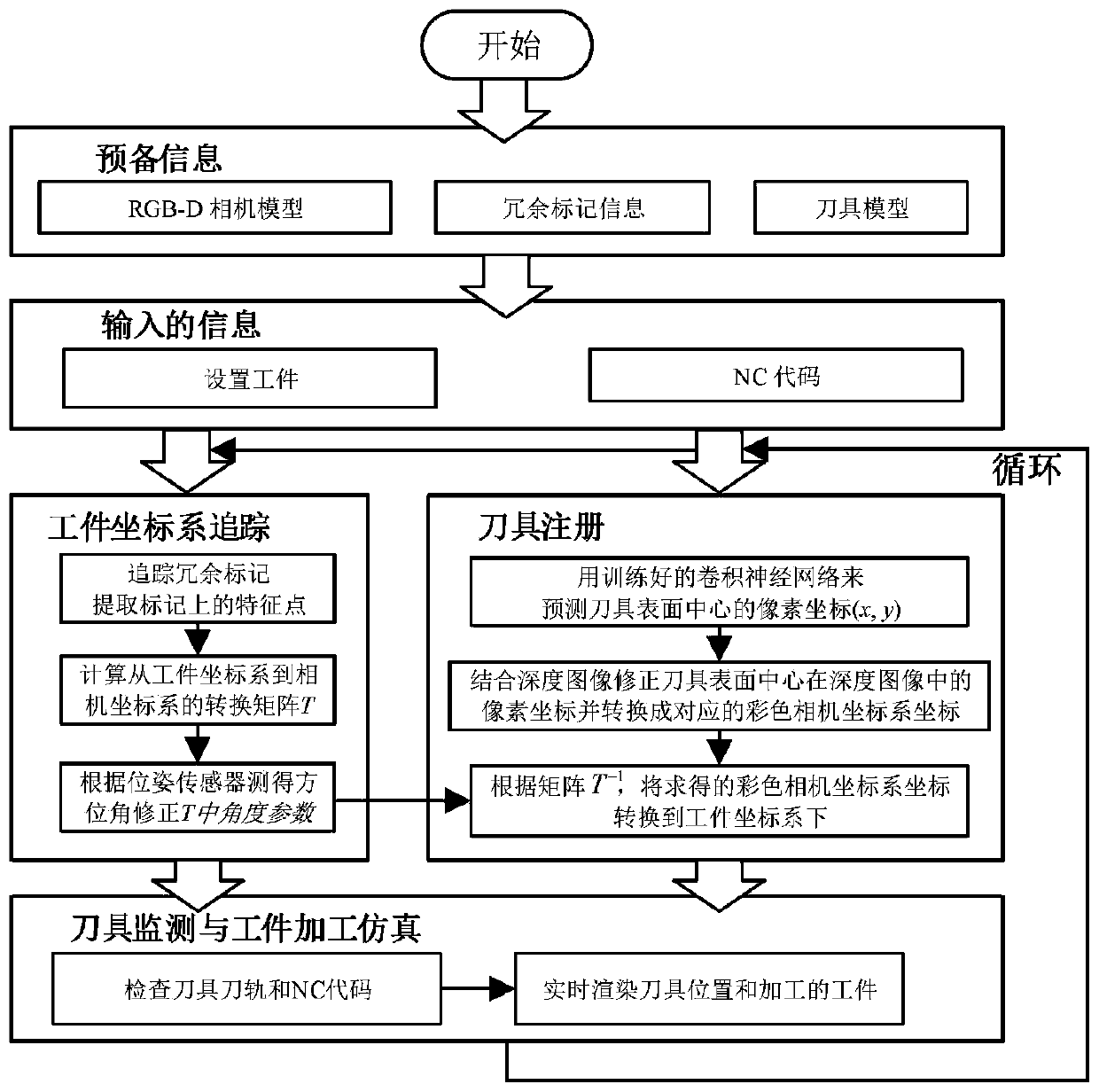

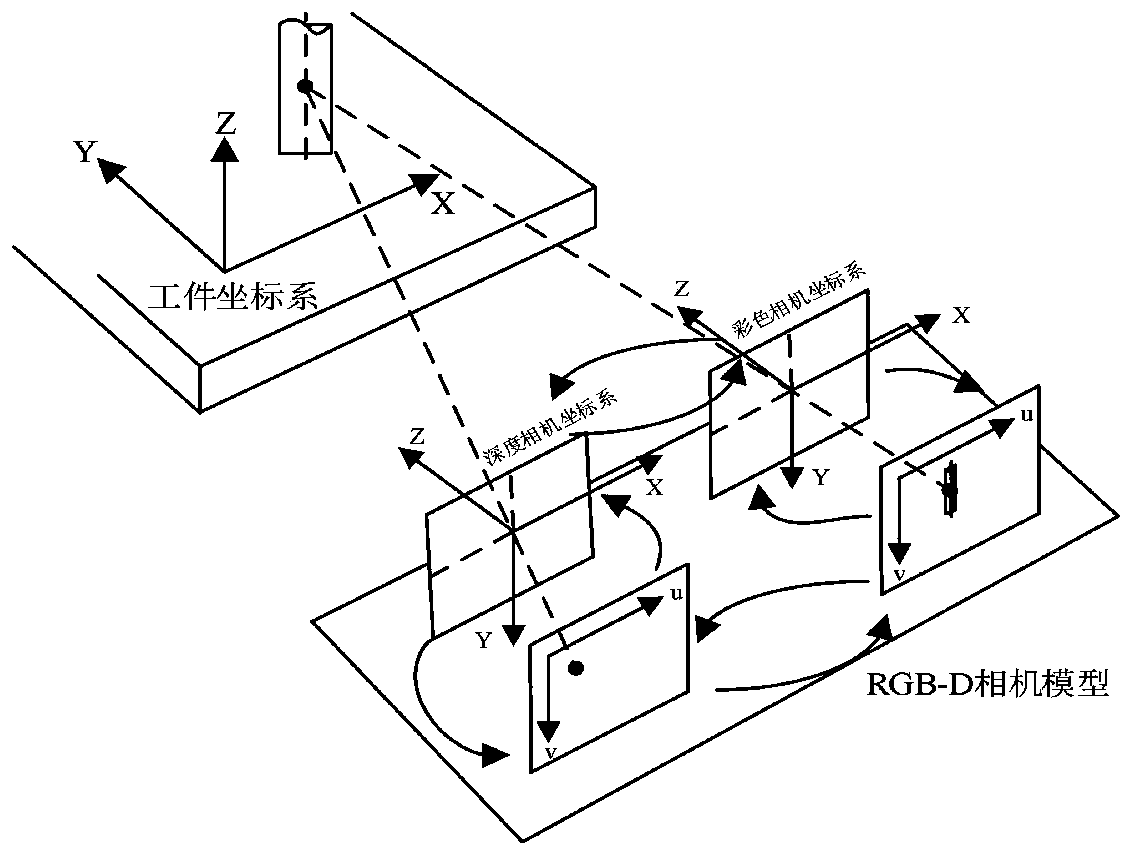

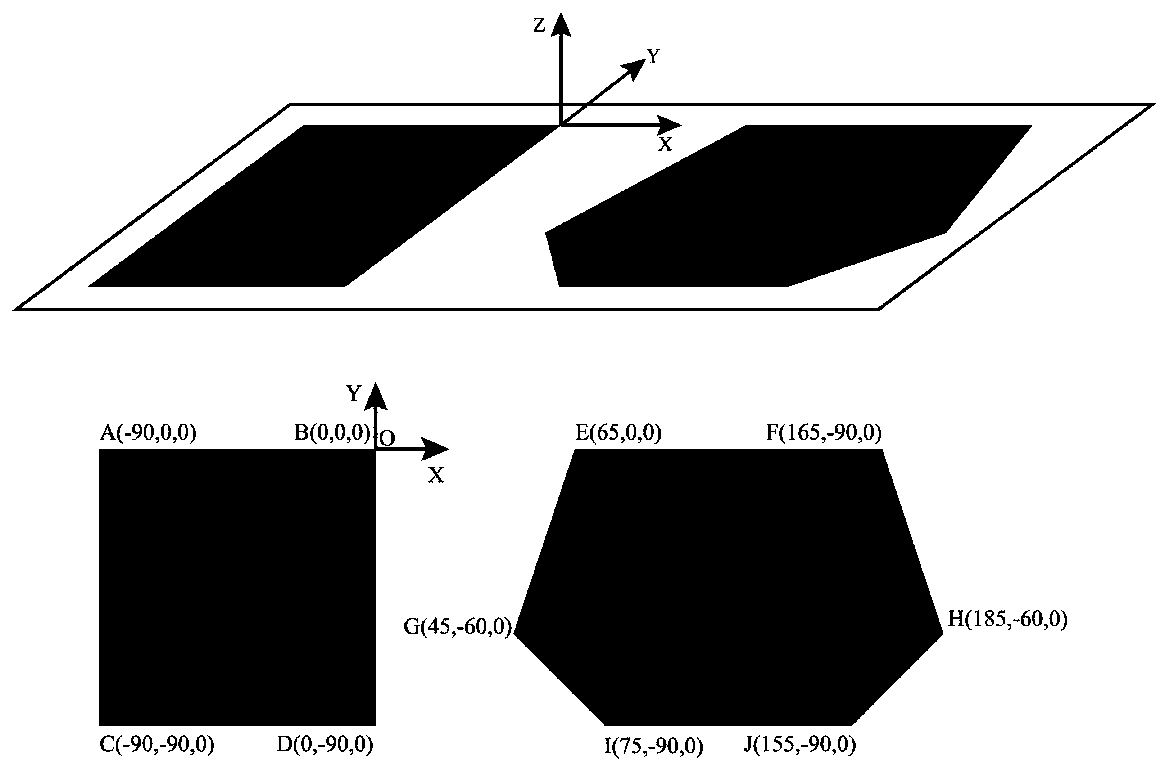

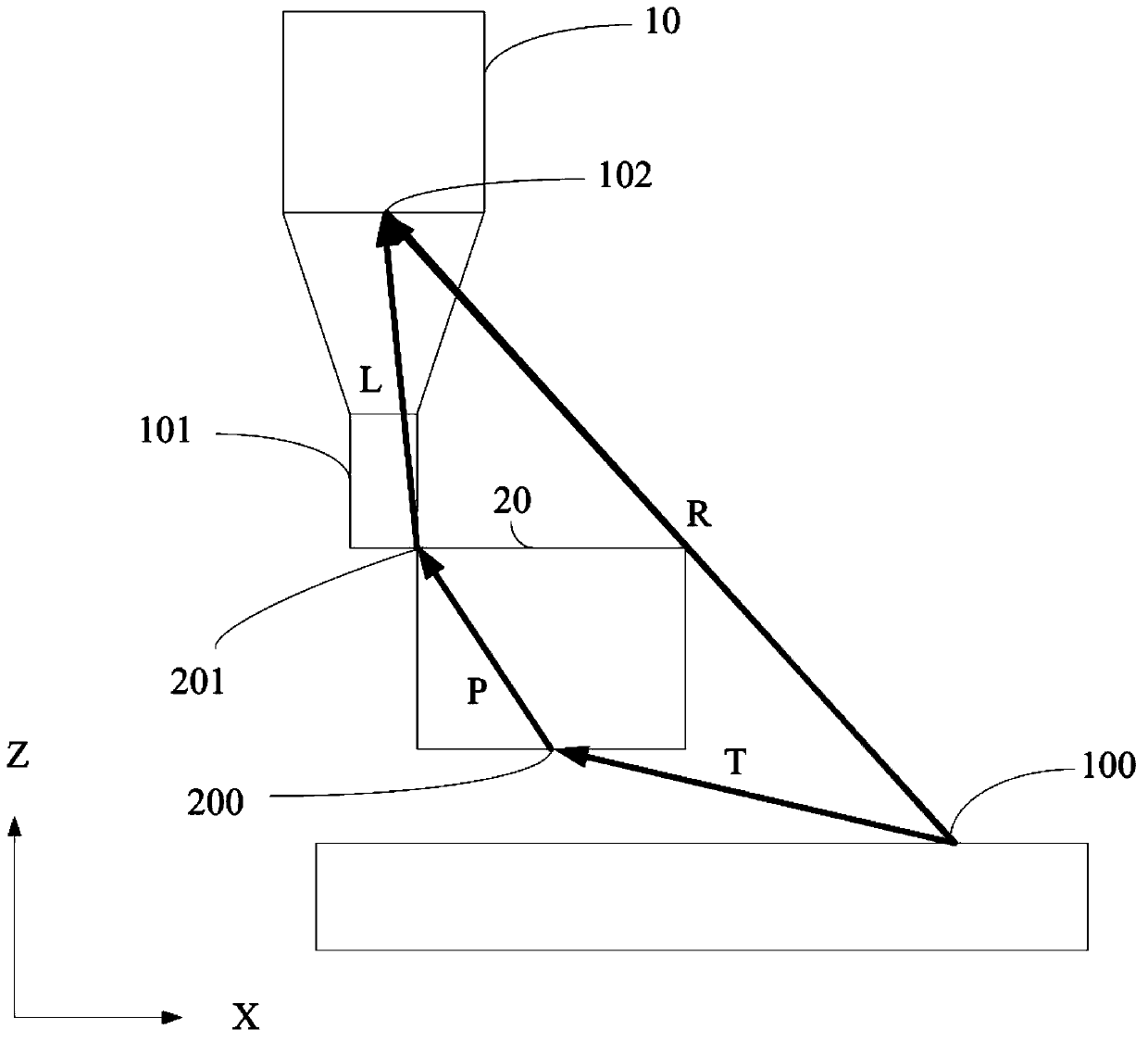

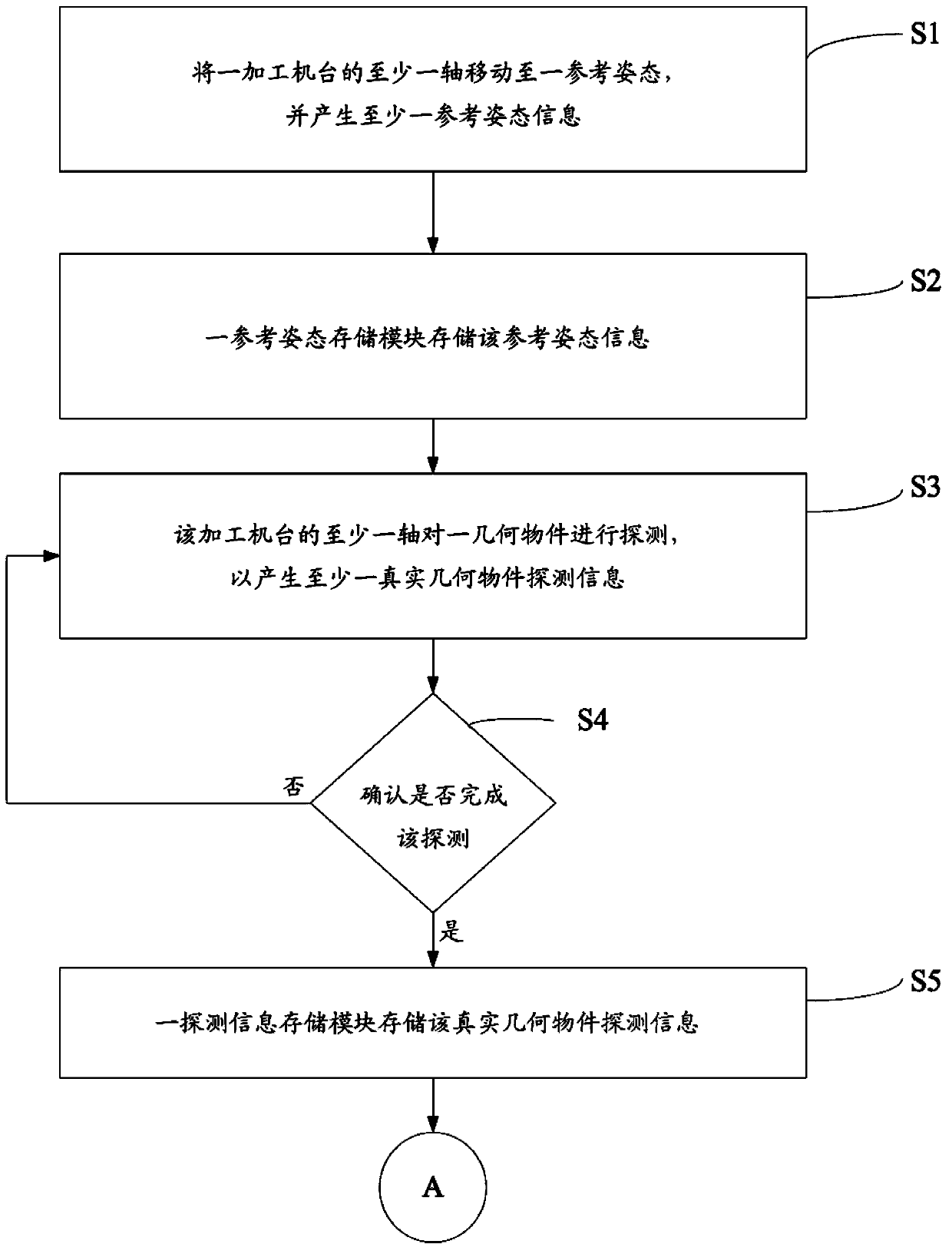

Numerical control NC code virtual and real verification method based on RGB-D camera

ActiveCN111062937AAvoid scrappingAvoid Tool Collision ProblemsImage enhancementImage analysisNumerical controlImage extraction

The invention discloses a numerical control NC code virtual and real verification method based on an RGB-D camera, and belongs to the field of machine tool machining simulation, and the method comprises the following steps: calibrating the internal and external parameters of a color camera and a depth camera in the RGB-D camera, and converting pixel coordinates into camera coordinate system coordinates; defining a workpiece coordinate system by using a redundant mark, and acquiring an image of the mark by using the RGB-D camera; extracting pixel coordinates of the feature points from the acquired image; calculating a transformation matrix from a camera coordinate system to a workpiece coordinate system; obtaining a calculation model for converting coordinates of a tool center point cameracoordinate system into coordinates of a workpiece coordinate system; constructing and training a neural network for cutter position detection; calculating cutter coordinates in real time after training; inputting NC codes and setting virtual workpiece size information by the machine tool; and verifying whether the tool performs machining on a tool path specified by the NC code or not. According tothe method, the problems of incomplete machine tool models in the simulation NC codes, difference between the virtual machine tool models and the actual machine tool and the like are solved, and thereliability and authenticity of machine tool NC code simulation are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

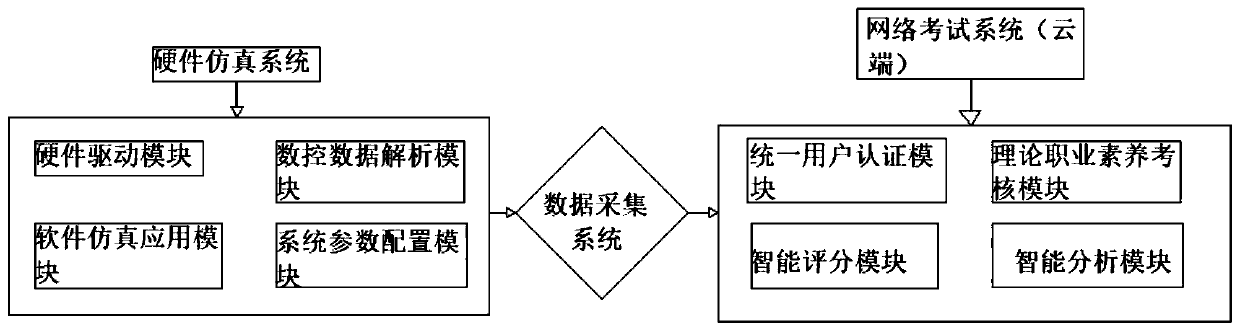

Numerical control training system

InactiveCN110930806AIncrease interest in learningAdd funCosmonautic condition simulationsSimulatorsNumerical controlData acquisition

The invention discloses a numerical control training system, which comprises a hardware simulation system, a data acquisition system and a network examination system; the hardware simulation system comprises a hardware driving module, a software simulation application module, a numerical control data analysis module and a system parameter configuration module; and the network examination system comprises a unified authentication module, a theoretical occupational quality assessment module, an intelligent scoring module and an intelligent analysis module. According to the system, a learner canobserve the virtual machine tool and understand structures of various numerical control equipment such as a numerical control lathe and a machining center so as to improve the learning interest, the effectiveness of numerical control programming learning and machine tool operation practice of learners can be met; the students can be exercised in both theoretical learning and actual operation in the using process, a networked on-line assessment function and an on-line automatic evaluation function can be achieved, multi-system, multi-platform and multi-model analog simulation operation practical training is supported, and the flexibility is high.

Owner:上海巅思智能科技有限公司 +1

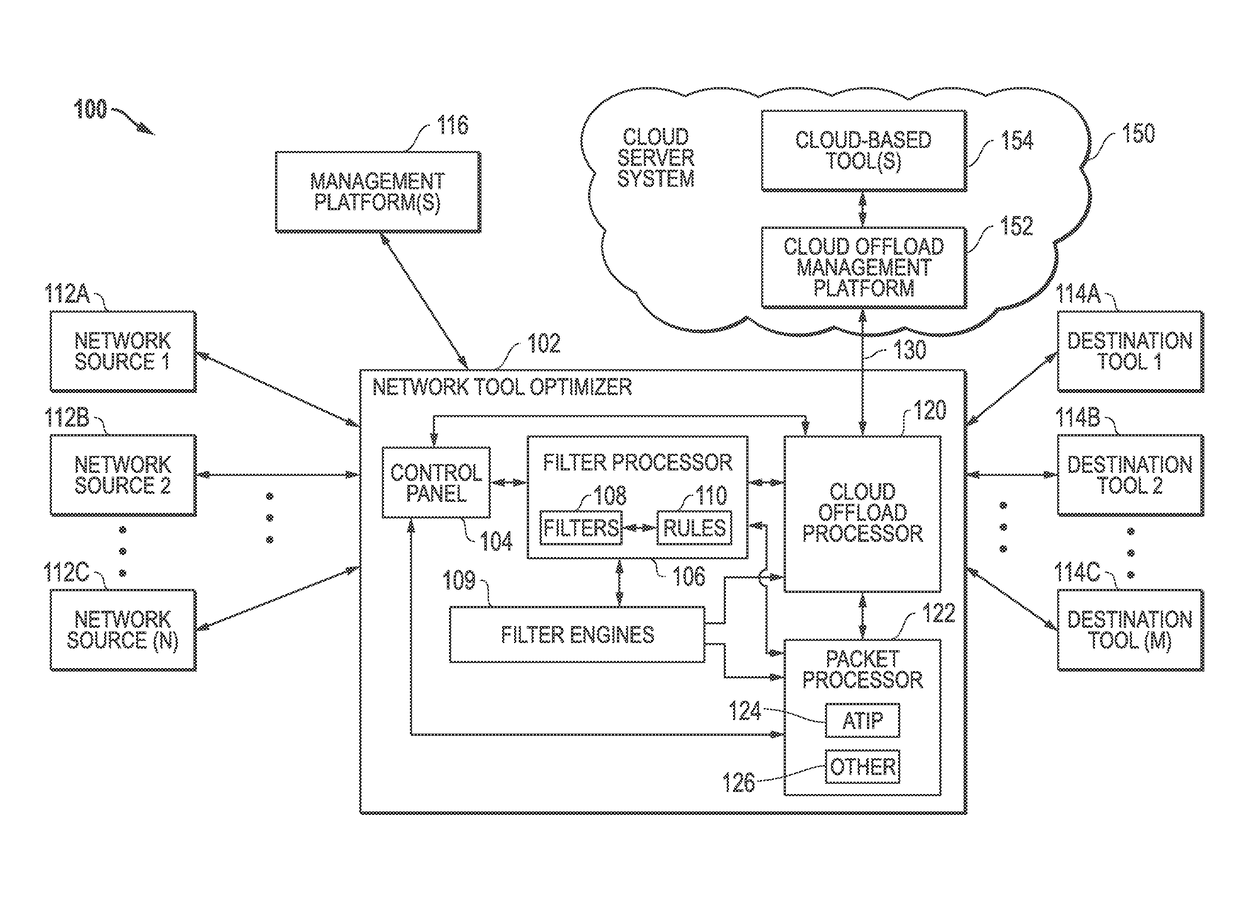

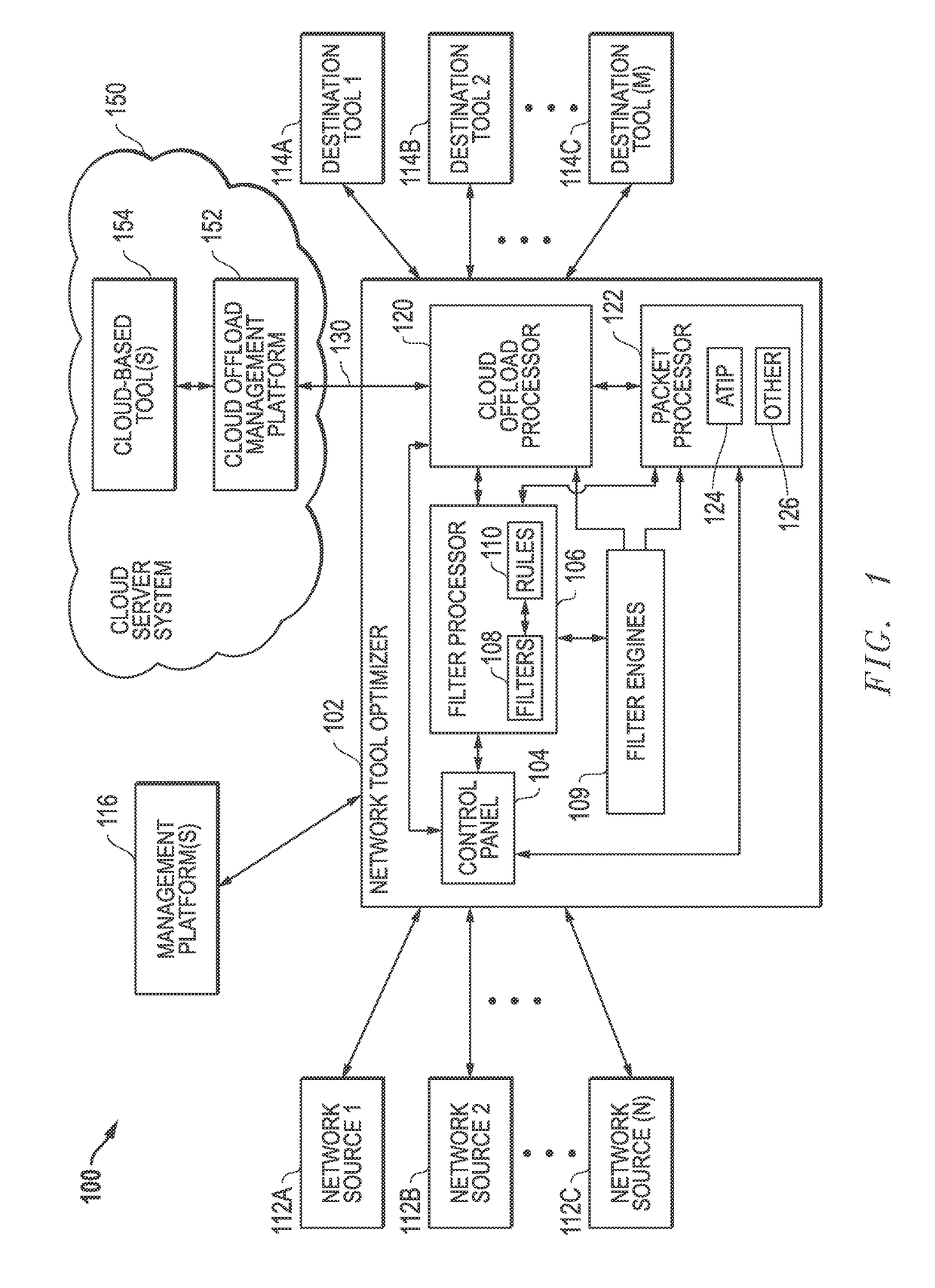

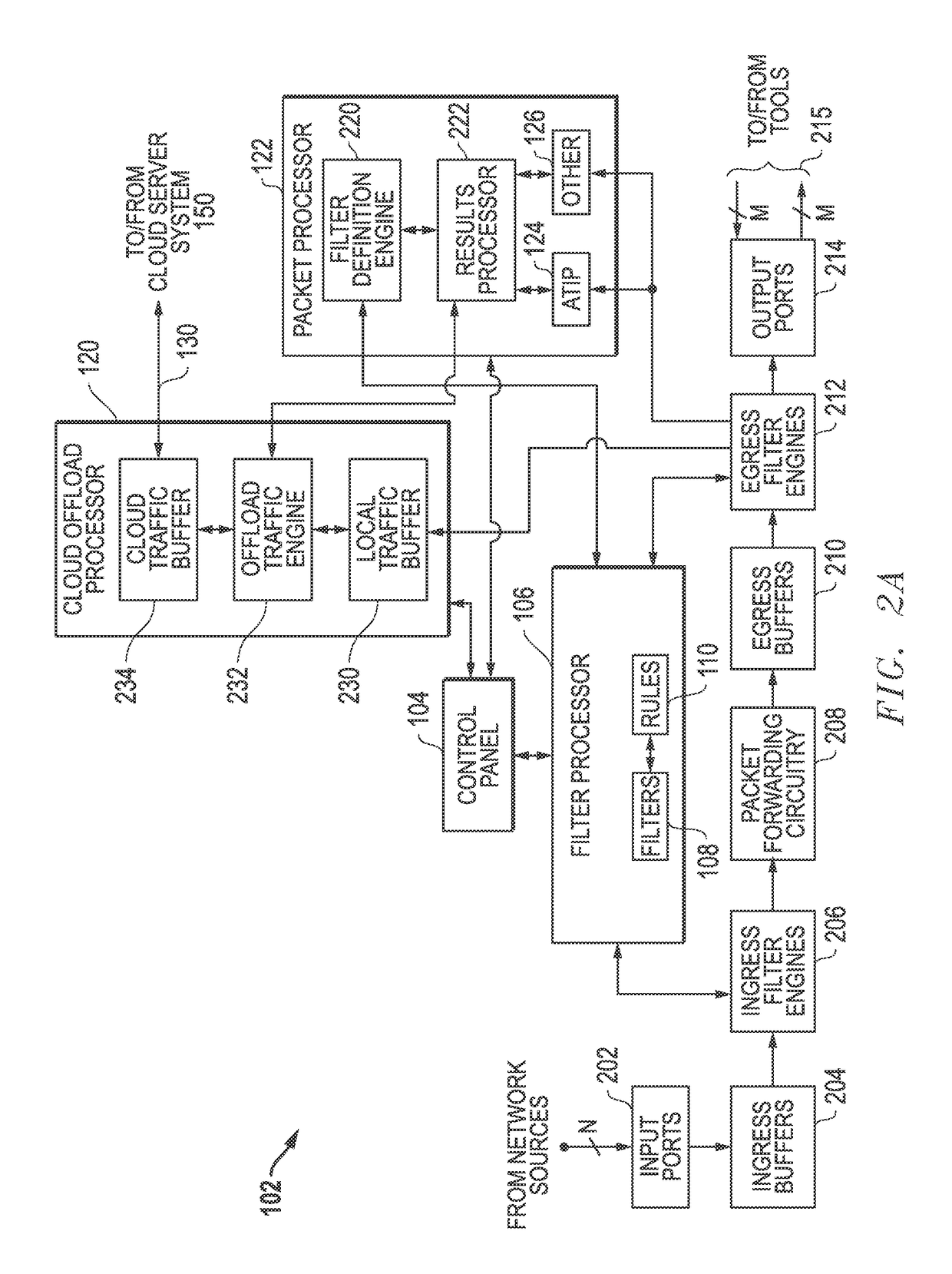

Selective scanning of network packet traffic using cloud-based virtual machine tool platforms

Network tool optimizer devices and related methods are disclosed that provide selective scanning of network packet traffic using cloud-based virtual machine tool platforms. Rather than require local network analysis tool resources, the disclosed embodiments identify subsets of packet traffic of interest, and these subsets are forwarded to a cloud-based server system where cloud-based virtual machine tool platforms are used to process the subsets of traffic of interest. Results from this processing are then provided back to adjust the operation of the network tool optimizers. Some further embodiments use local capture buffers and remote cloud replay buffers to stored subsets of traffic locally for later communication to cloud server systems where cloud-based tools analyze replays of the captured network traffic. Some further embodiments also use results from cloud-based tools to initiate local virtual machine tool platforms that are used to further analyze traffic of interest.

Owner:KEYSIGHT TECH SINGAPORE (SALES) PTE LTD

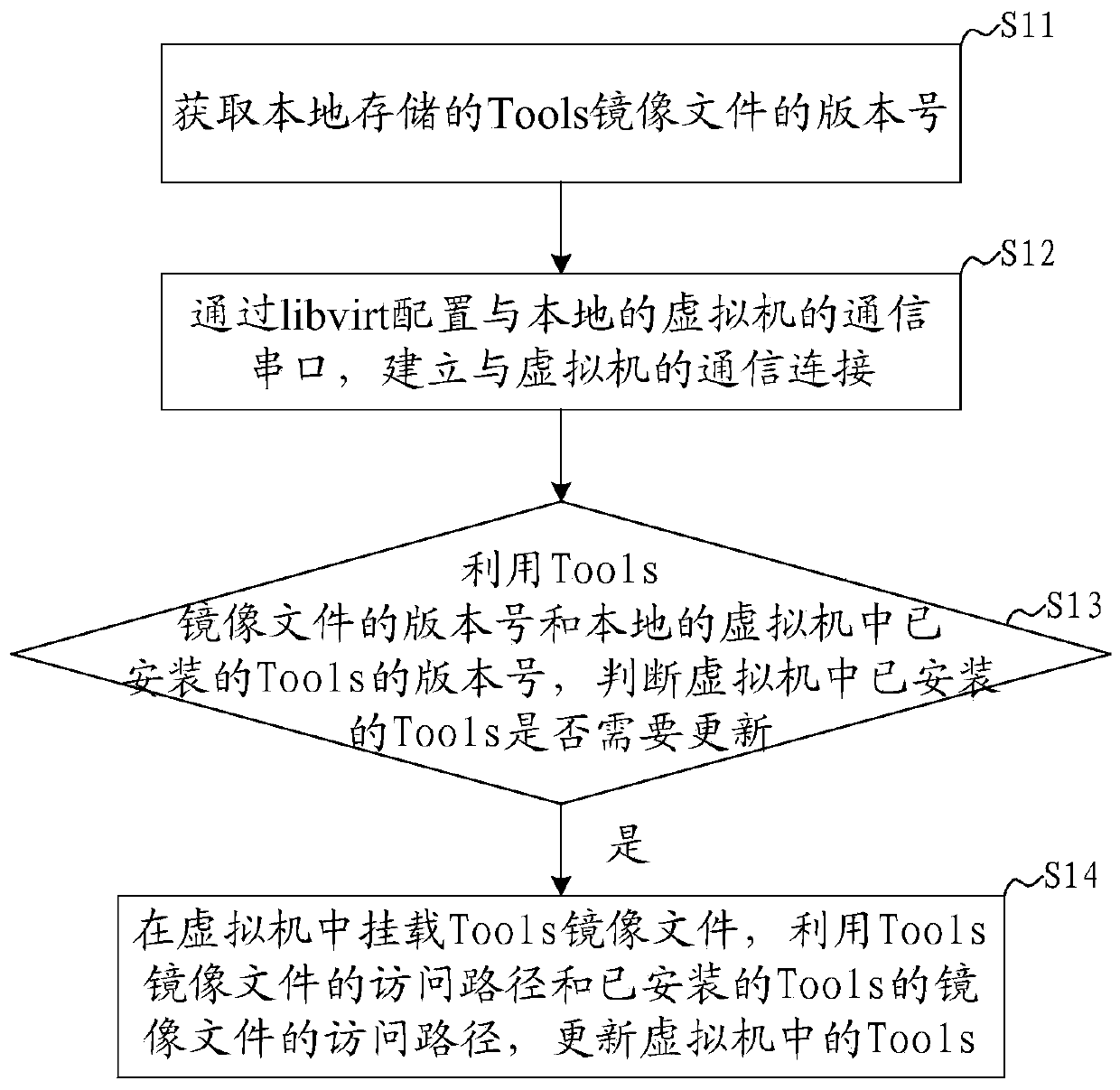

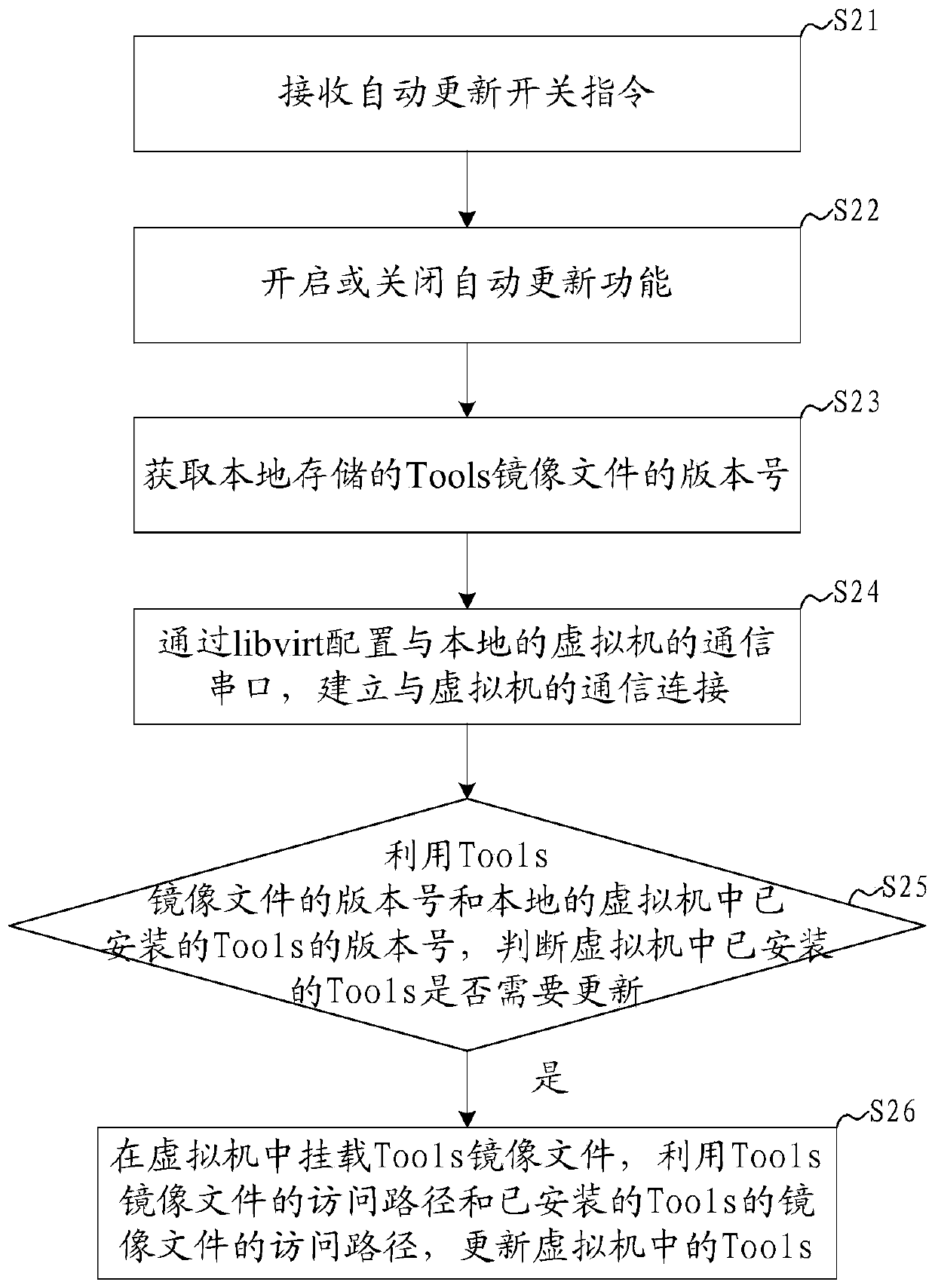

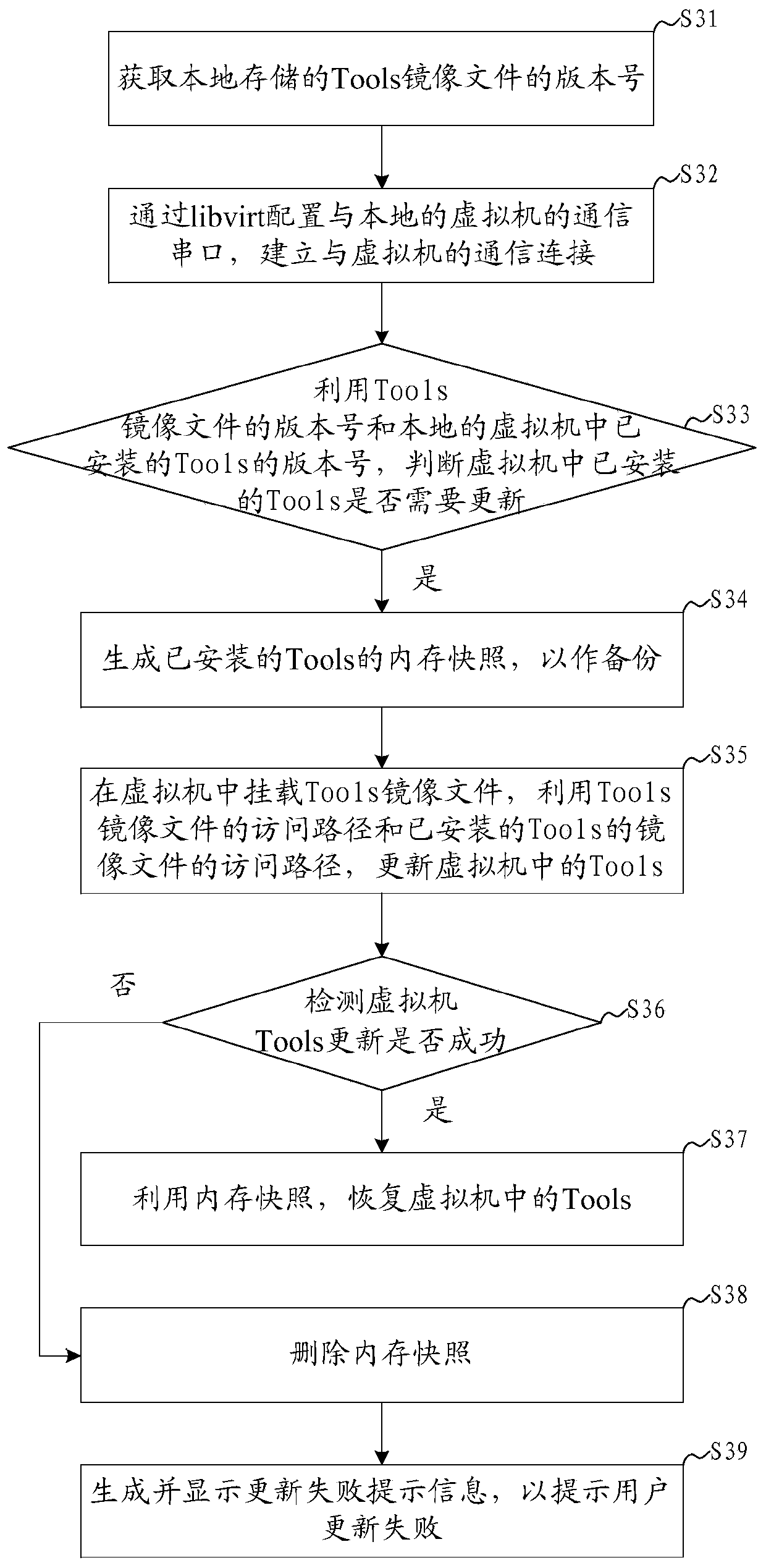

Virtual machine Tools updating method, system, device and readable storage medium

InactiveCN111061537AImplement automatic updatesNo manual updateVersion controlSoftware simulation/interpretation/emulationMirror imageVirtual machine tool

The invention discloses a virtual machine Tools updating method, a system, a device and a computer readable storage medium. The method comprises the steps of obtaining a version number of a locally stored Tools mirror image file; configuring a communication serial port with a local virtual machine through libvirt, and establishing communication connection with the virtual machine; judging whetherthe Tools installed in the virtual machine need to be updated by utilizing the version number of the Tools mirror image file and the version number of the Tools installed in the virtual machine; if the Tools mirror image file needs to be updated, mounting the Tools mirror image file in the virtual machine, and updating the Tools in the virtual machine by utilizing the access path of the Tools mirror image file and the access path of the installed Tools mirror image file; according to the method, the version number of the Tools mirror image file outside the virtual machine is automatically obtained; by comparing the version number of the Tools installed in the virtual machine with the version number of the Tools mirror image file outside the virtual machine, whether the version of the Toolsin the virtual machine needs to be updated is judged, and after it is judged that the version of the Tools needs to be updated, automatic updating is achieved, manual updating is not needed, and theupdating efficiency is higher.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

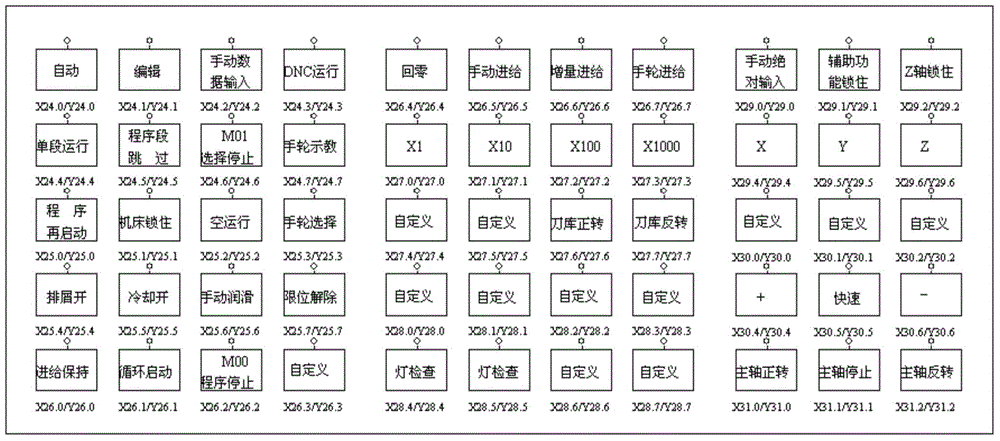

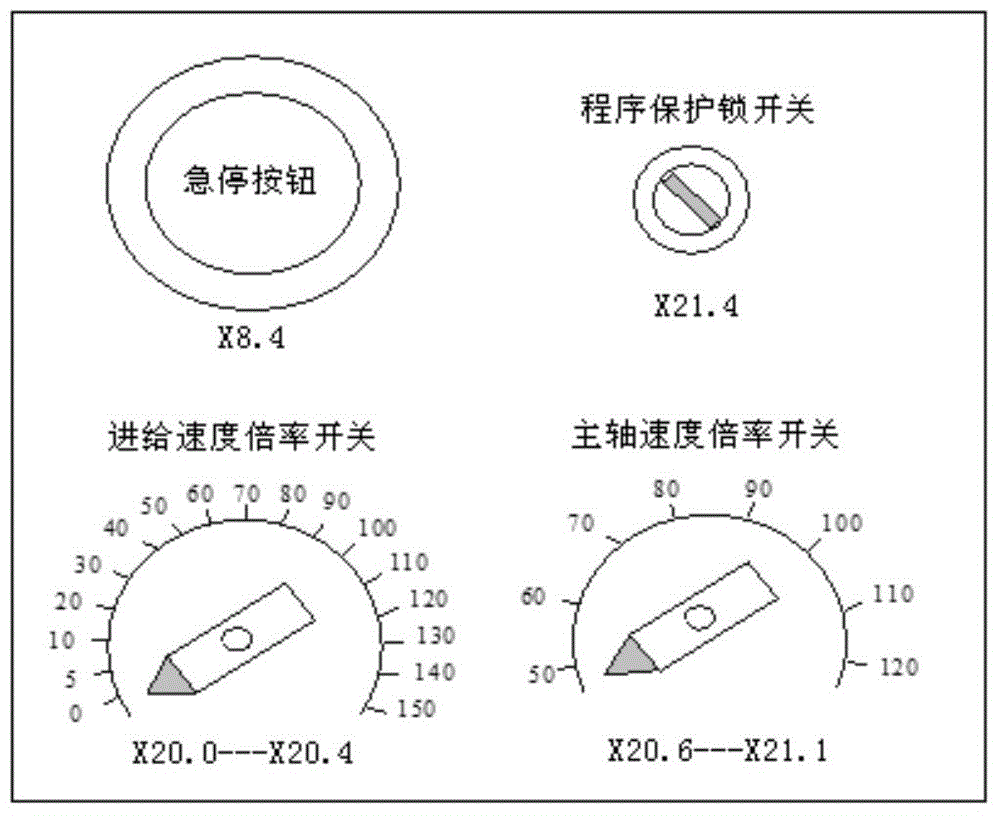

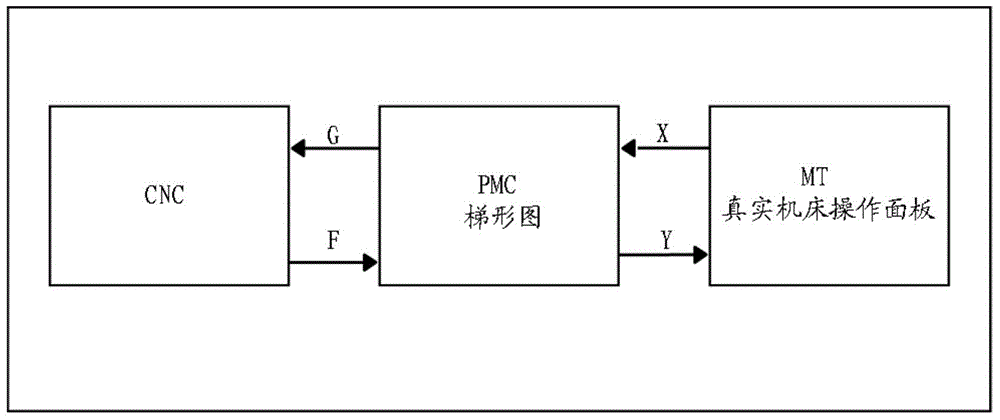

Online machine tool panel operation control method for numerically-controlled machine tool

ActiveCN104460510AAchieve sharingRealize online controlNumerical controlControl systemHigh-level programming language

The invention relates to an online machine tool panel operation control method for a numerically-controlled machine tool. The method includes the following steps that S1, a client is provided with a virtual machine tool operation panel, and the control function achieved by the virtual machine tool operation panel is the same as that of a real machine tool operation panel; S2, the client achieves sequential control over signals generated in the operating process of the numerically-controlled machine tool through a ladder diagram PMC program in a numerically-controlled system by means of the high-level programming language, and operation of the real machine tool operation panel is transferred to the virtual machine tool operation panel on a computer screen of the client. By means of the online machine tool panel operation control method, network resource sharing can be achieved, online control over the numerically-controlled machine tool can be achieved as well, and the digital service level of numerically-controlled devices is greatly increased.

Owner:曹智军

Method for realizing virtual machine tool model-based cloud terminal numerical control system and virtual machine tool model-based cloud terminal numerical control system

ActiveCN102736553BTake advantage of high-end featuresLow costTransmissionNumerical controlTerminal serverWorking environment

The invention discloses a method for realizing a virtual machine tool model-based cloud terminal numerical control system and the virtual machine tool model-based cloud terminal numerical control system. The method comprises the following steps of: establishing a corresponding virtual machine tool model module for each numerical control device lower computer, wherein the virtual machine tool model modules comprise basic parameters of machine tools and data systems; finishing human-computer interaction processes, inputting and preprocessing numerical control processing programs and decoding the numerical control processing programs by using cloud terminal servers, namely remote servers; and communicating the cloud terminal servers with the numerical control device lower computers through a network. The system comprises cloud terminal upper computers for preprocessing and decoding the numerical control processing programs, the numerical control device lower computers and at least one virtual machine tool model module for storing the basic parameters of the machine tools and the data systems, wherein the lower computers communicate with the cloud terminal upper computers and are used for controlling the speeds and the positions of the machine tools. By the method and the system, the cost of a production enterprise can be substantially reduced, and a comfortable working environment can be provided for machine tool operators at the same time.

Owner:WUHAN HUAZHONG NUMERICAL CONTROL +1

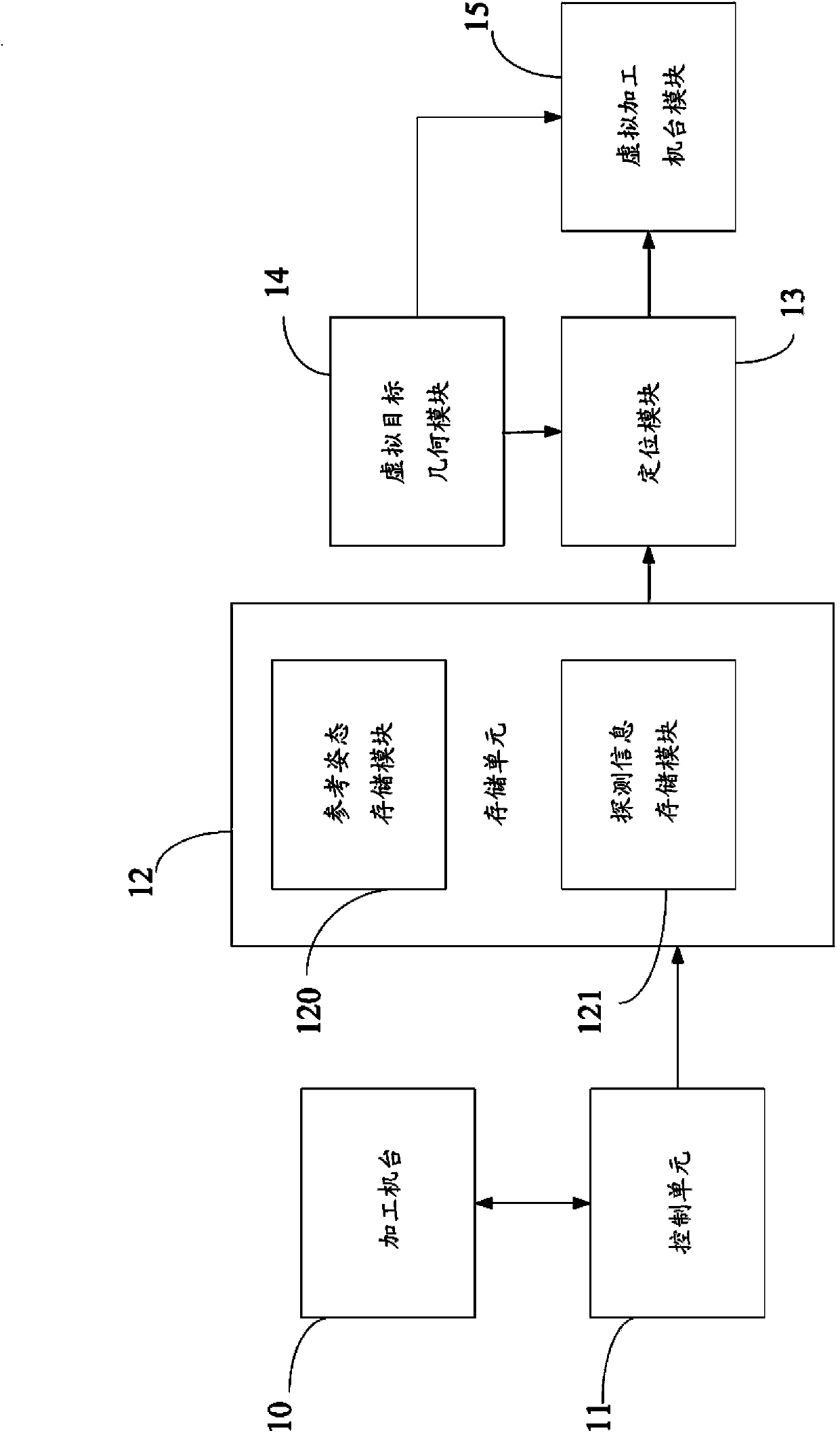

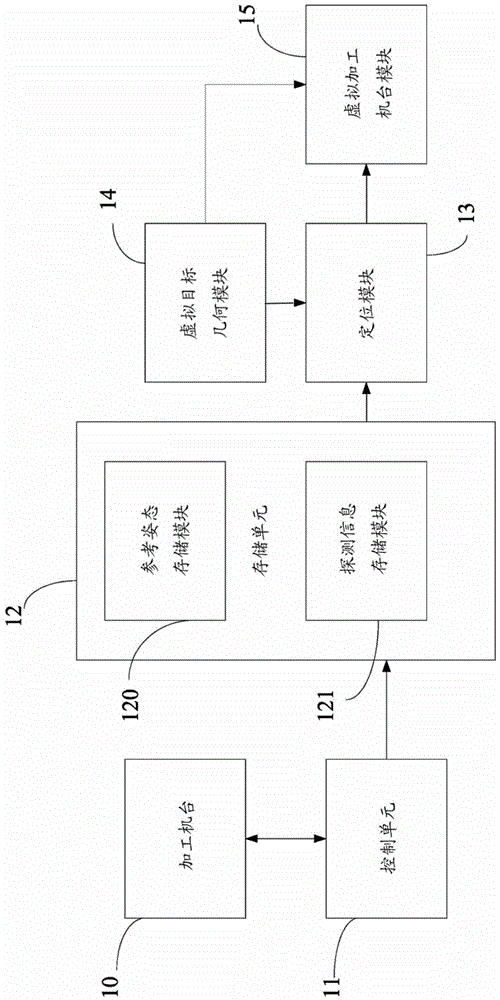

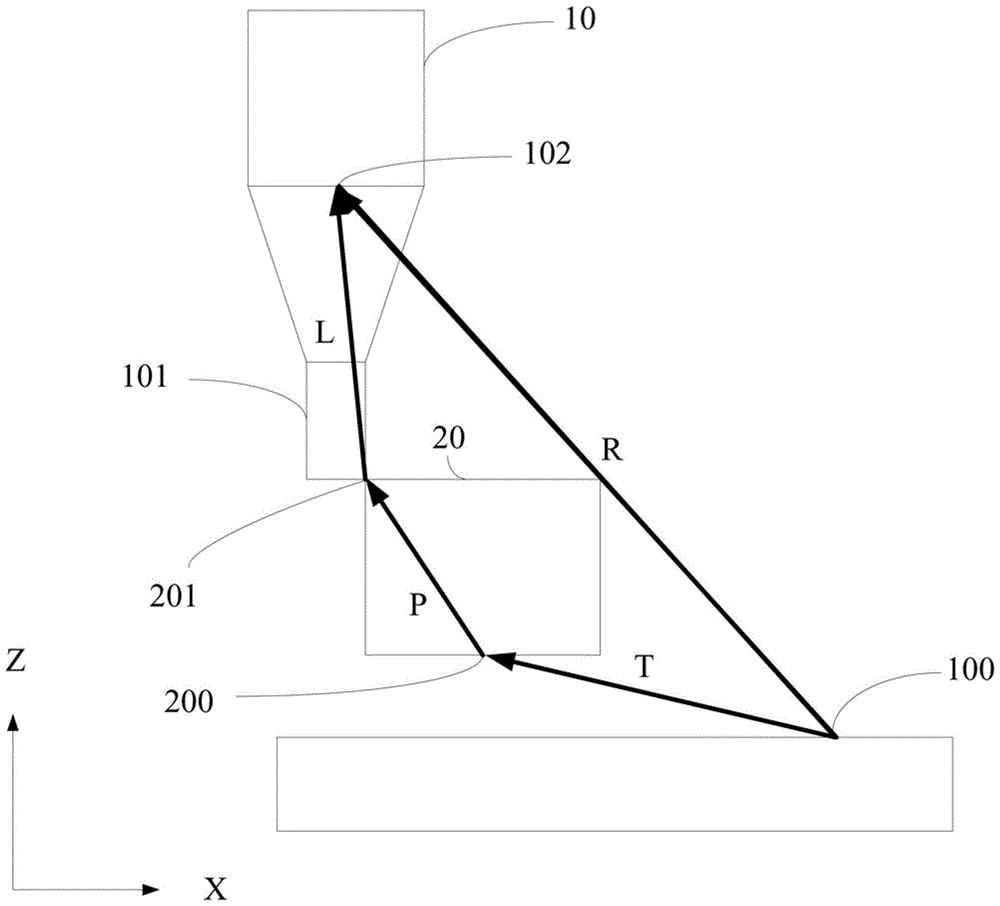

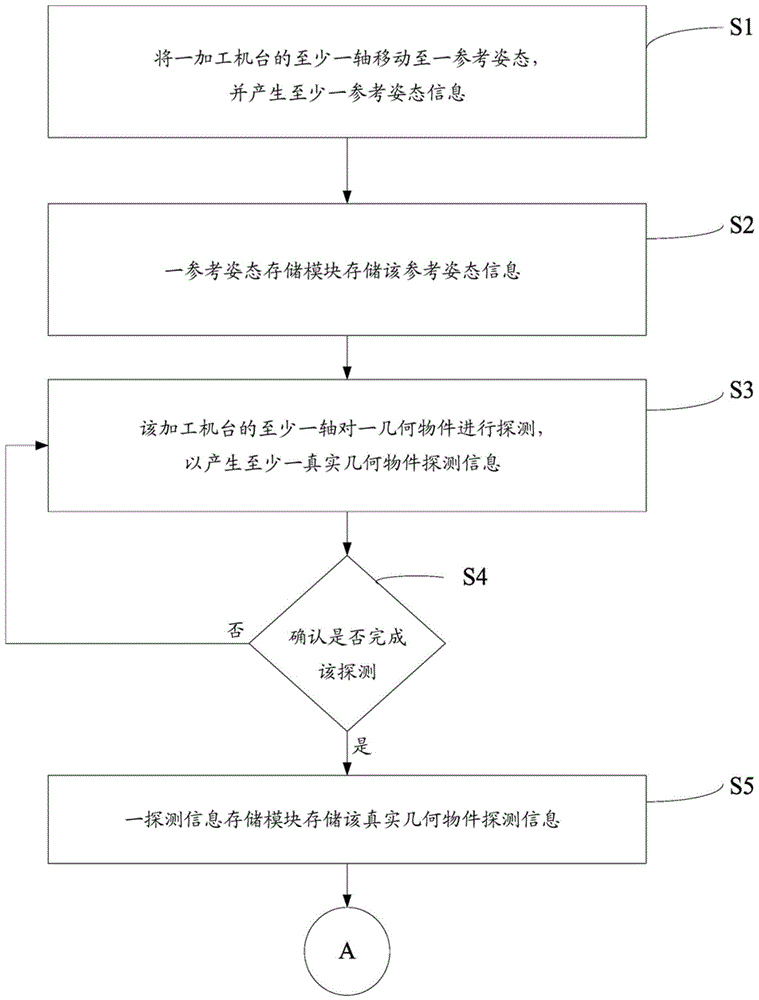

Apparatus and method for positioning geometric model

Apparatus for positioning geometric model, which comprises: a machine tool; a control unit, electrically coupled to the machine tool; a storage unit, electrically coupled to the control unit; a positioning module, electrically coupled to the storage unit; a virtual target geometry module, electrically coupled to the positioning module; and a virtual machine tool module, electrically and respectively coupled to the virtual target geometry module and the positioning module.

Owner:IND TECH RES INST

Method, device and system for verifying machine tool code

ActiveCN103048952BAccurate verificationAccurate analysisProgramme controlComputer controlValidation methodsVirtual machine tool

The invention discloses a verification method, device and system of machine tool machining codes. The method comprises the following steps that: a numerical control system receives the machining codes; the numerical control system uses the machining codes to obtain control instructions; a simulation system uses the control instructions to drive a virtual machine tool to carry out workpiece machining operation, wherein the virtual machine tool is a previously simulated machine tool model; the simulation system acquires machine tool operation data generated in the workpiece machining operation process of the virtual machine tool; the simulation system judges whether the machine tool operation data are accordant with preset operation data, wherein the preset operation data are prestored operation data, corresponding to the machining codes, of the machine tool; and the simulation system confirms that the machining codes are qualified in verification under the condition that the machine tool operation data are accordant with the preset operation data. The effect of accurately analyzing the machining codes so as to accurately verify the machining codes is achieved.

Owner:CAXA TECH

Geometric positioning device and method thereof

Owner:IND TECH RES INST

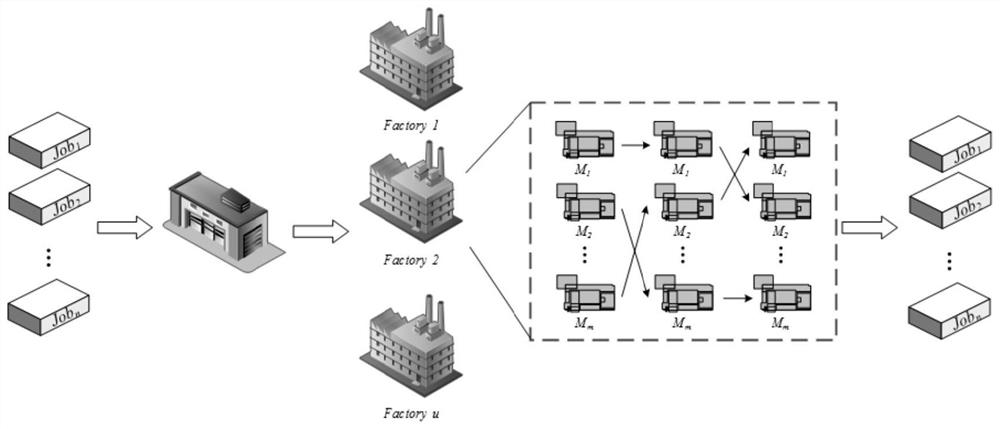

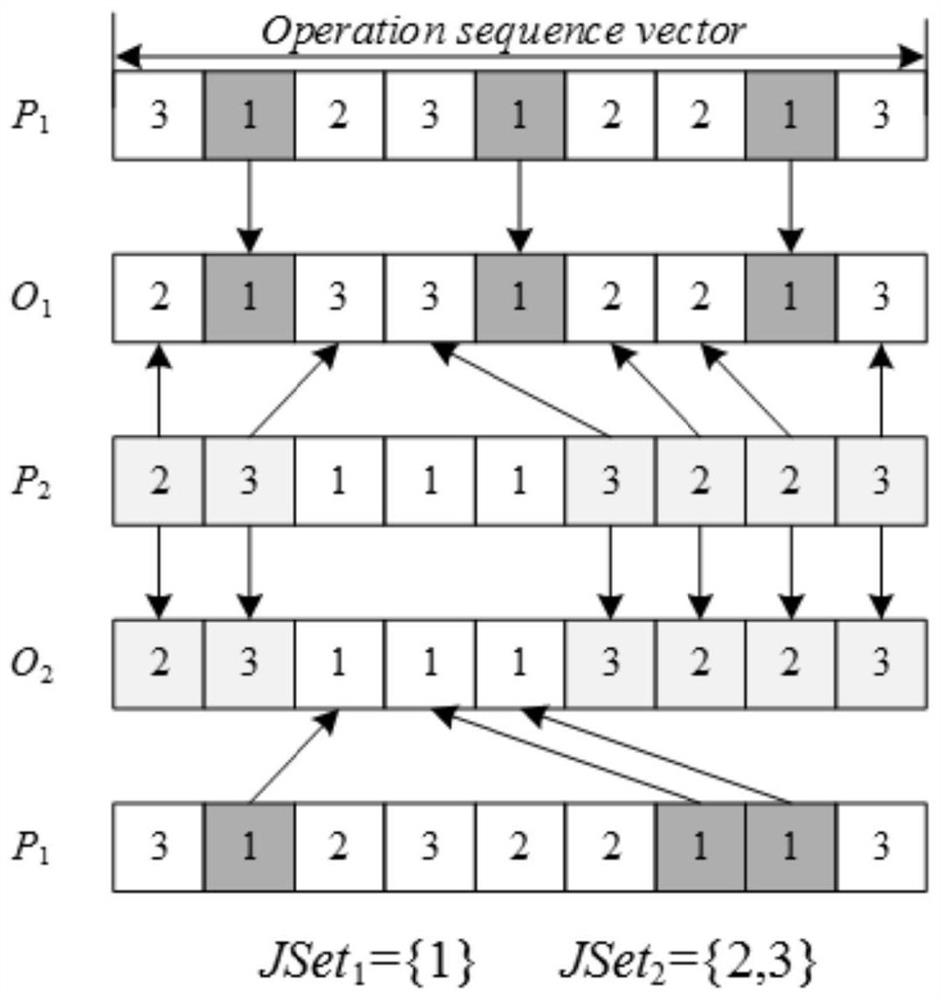

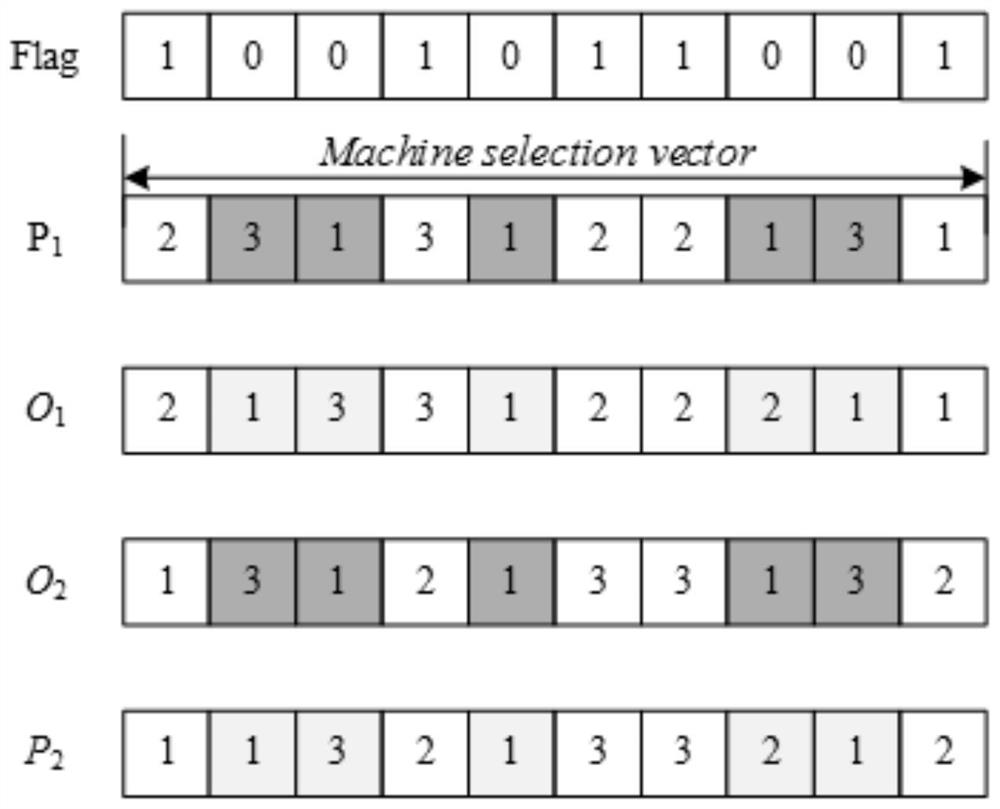

Distributed flexible workshop scheduling method and system with transportation process

PendingCN114519455AVerify validityVerify feasibilityForecastingArtificial lifeCompletion timeMathematical model

The invention provides a distributed flexible workshop scheduling method and system with a transportation process, and the method comprises the steps: obtaining the information of a to-be-processed workpiece, and the related information of a distributed flexible workshop; obtaining a scheduling result according to the to-be-processed workpiece information, the distributed flexible workshop related information and a preset distributed flexible workshop scheduling model; wherein the distributed flexible workshop scheduling model is set to be a sequence-based mixed integer linear programming model for simultaneously optimizing the completion time and the total energy consumption by using a weighted sum method; when the transportation time between the machine tools is determined, a virtual machine tool is preset, and the process of conveying each workpiece by the virtual machine tool is set as a first process; according to the method, the typical constraint condition of transportation time between machine tools is considered, the completion time and the total energy consumption in the multi-objective problem are optimized at the same time by using a weighted sum method, and a sequence-based MILP mathematical model is established for the first time.

Owner:SHANDONG NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com