Gaseous fuel combustion apparatus for an internal combustion engine

A technology of combustion device and gas fuel, which can be applied to fuel injection device, internal combustion piston engine, gaseous engine fuel, etc., and can solve problems such as reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

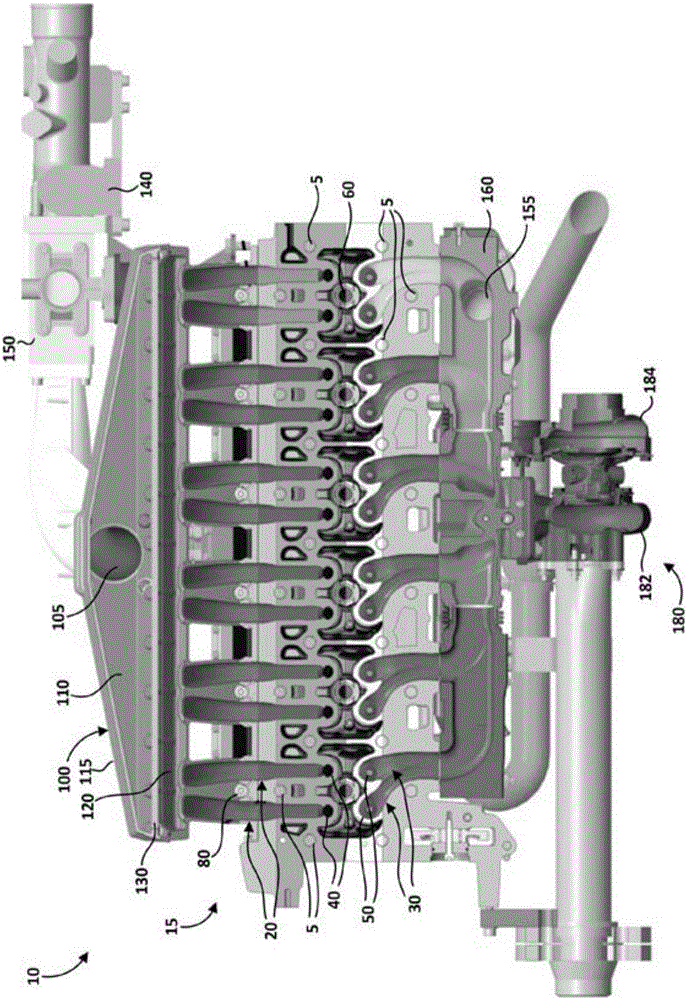

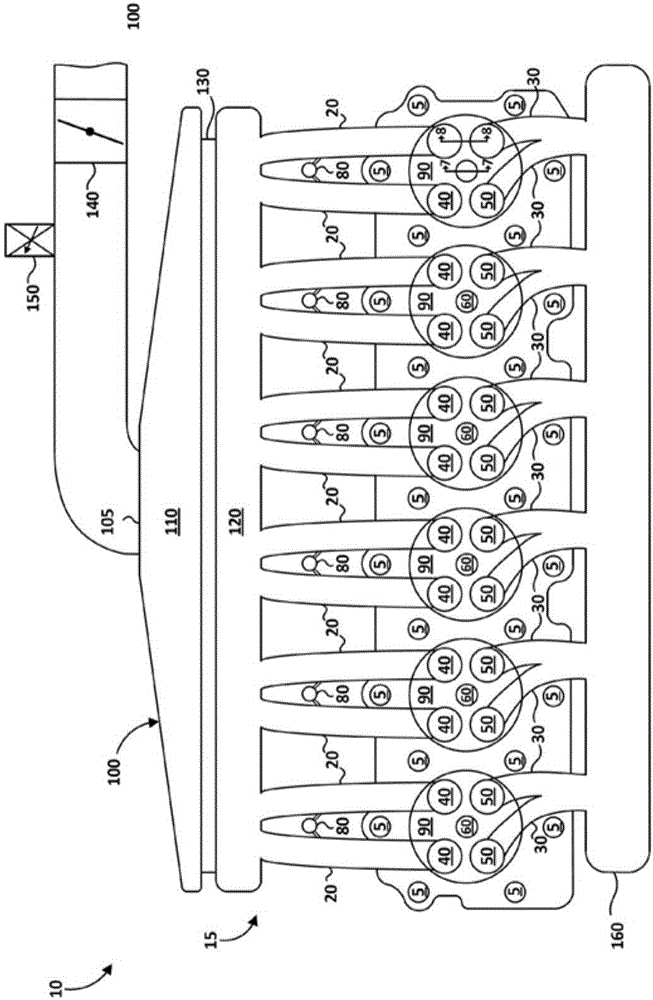

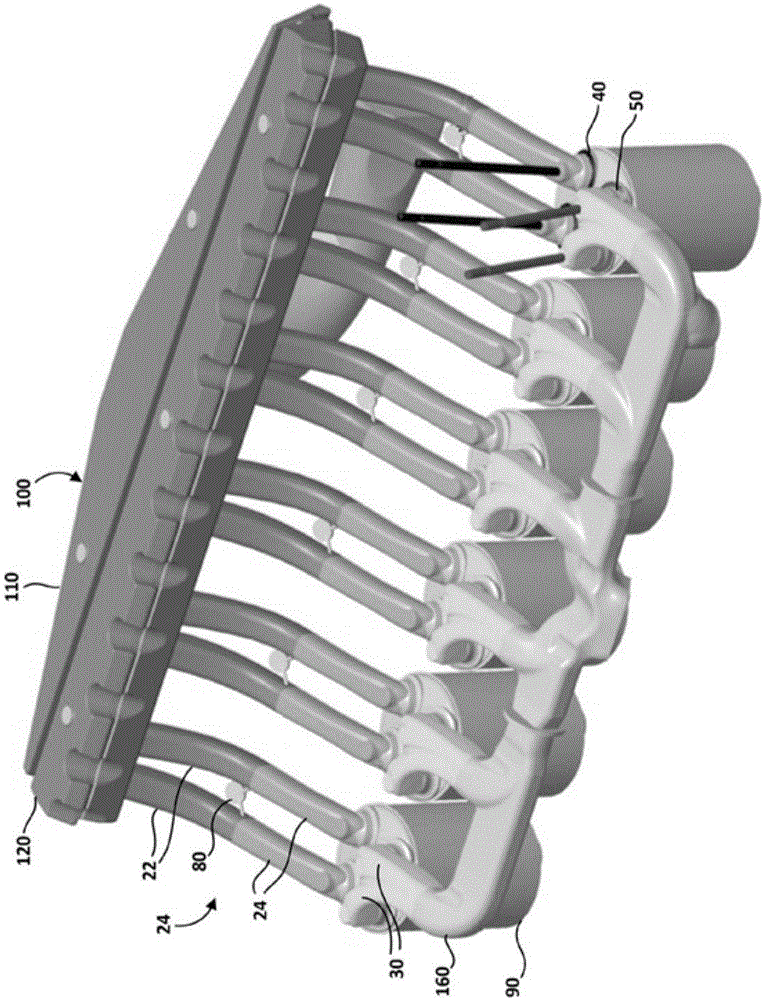

[0028] With reference to the attached drawings and first to figure 1 and figure 2 , shows an engine 10 including a gas fuel combustion device 15 according to a first embodiment. The feed manifold 100 includes a first distribution chamber 110 and a second distribution chamber 120 , also referred to as plenum chambers, in fluid communication with each other through a disperser 130 . First distribution chamber 110 is in fluid communication with throttle valve 140 to receive an air charge from the intake port of engine 10 and, when engine 10 employs exhaust gas recirculation, EGR valve 150 is operable to allow exhaust gas to enter the intake air stream . A pair of feed passages 20 extend along each side of one cylinder head bolt 5 and fluidly connect the second distribution chamber 120 with a respective feed valve 40 for each cylinder 90 . Each feed channel 20 includes a feed runner 22 connected to the second distribution chamber 120 and a feed port 24 located in the cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com