Load carrier and pressure spring for the upper roller of the drafting unit

A technology of drafting device and pressure spring, which is applied in the direction of drafting equipment, textiles, papermaking, spinning machines, etc., can solve the problems of unsatisfactory textile results and disadvantages, and achieve the effect of simple fixing possibility and uniform fiber strands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

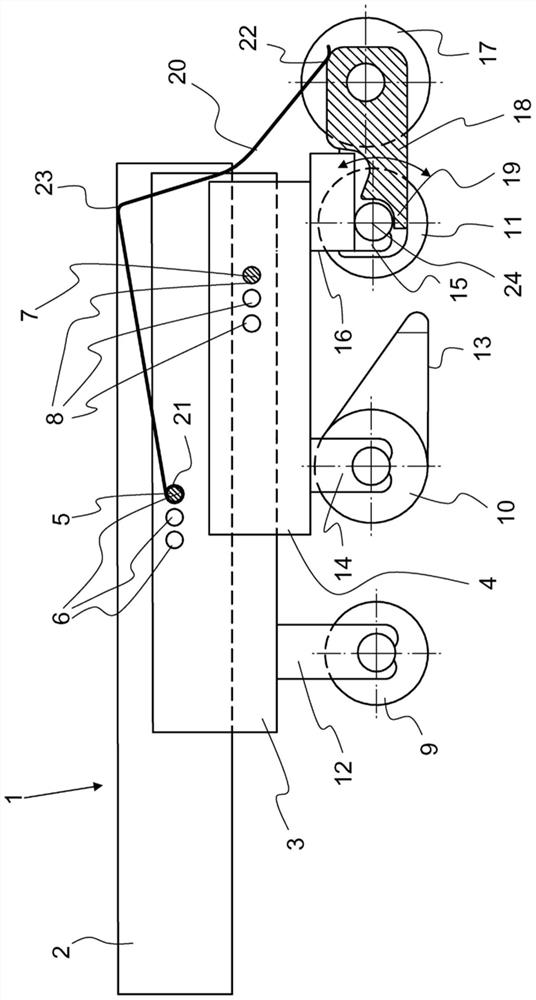

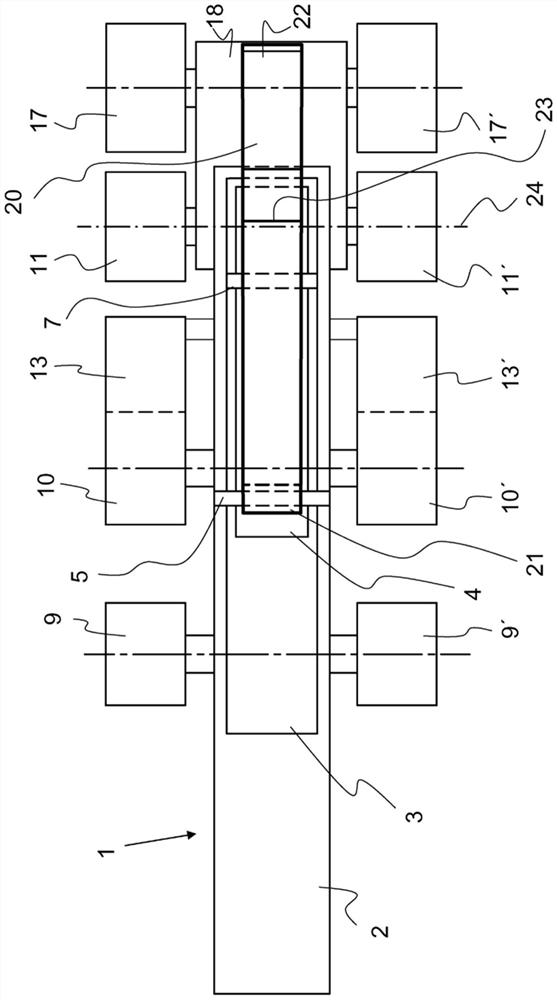

[0029] exist figure 1 A longitudinal section through a load carrier 1 according to the invention is shown in . The load carrier 1 has a guide rail 2 , a first bridge 3 and a second bridge 4 . The first bridge portion 3 is provided on the guide rail 2 in a rotatable manner by means of a rotary shaft 5 . The axis of rotation 5 is thus fixed in one of the three openings 6 and thus causes the first bridge 3 to be rotatably mounted in the guide rail 2 . The second bridge 4 is rotatably connected to the first bridge 3 via a further axis of rotation 7 in one of the three openings 8 . The openings 6 and 8 are preferably provided correspondingly in the first bridge part 3 and the guide rail 2 or in the second bridge part 4 and the first bridge part 3 in order to induce the rotation shaft 5 or the rotation shaft 7 as a first bridge The connection between the part 3 and the guide rail 2 or the connection between the second bridge part 4 and the first bridge part 3 . Depending on the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com