tube bundle reactor

A tube bundle reactor and reaction technology, applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc., can solve problems such as side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

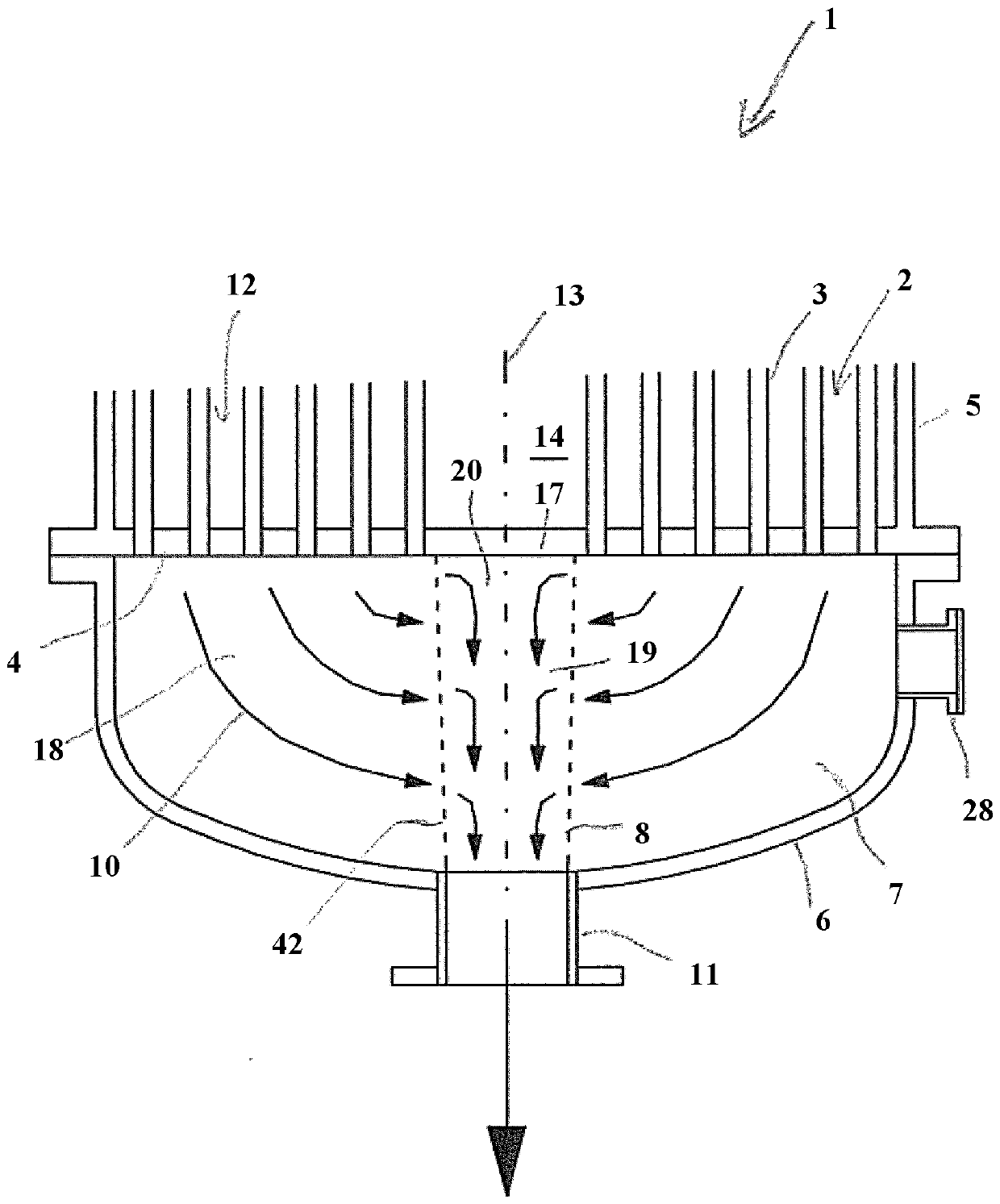

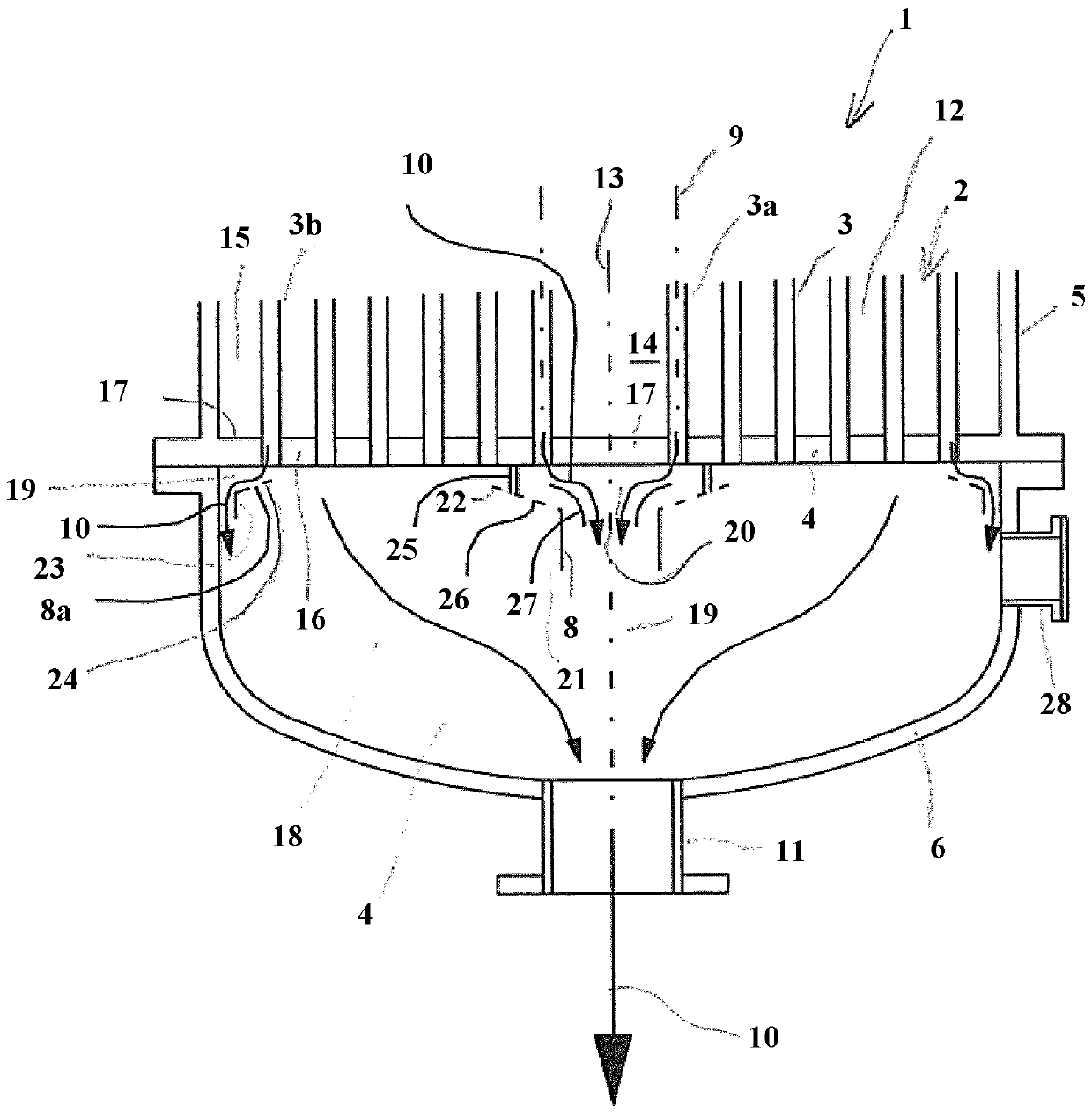

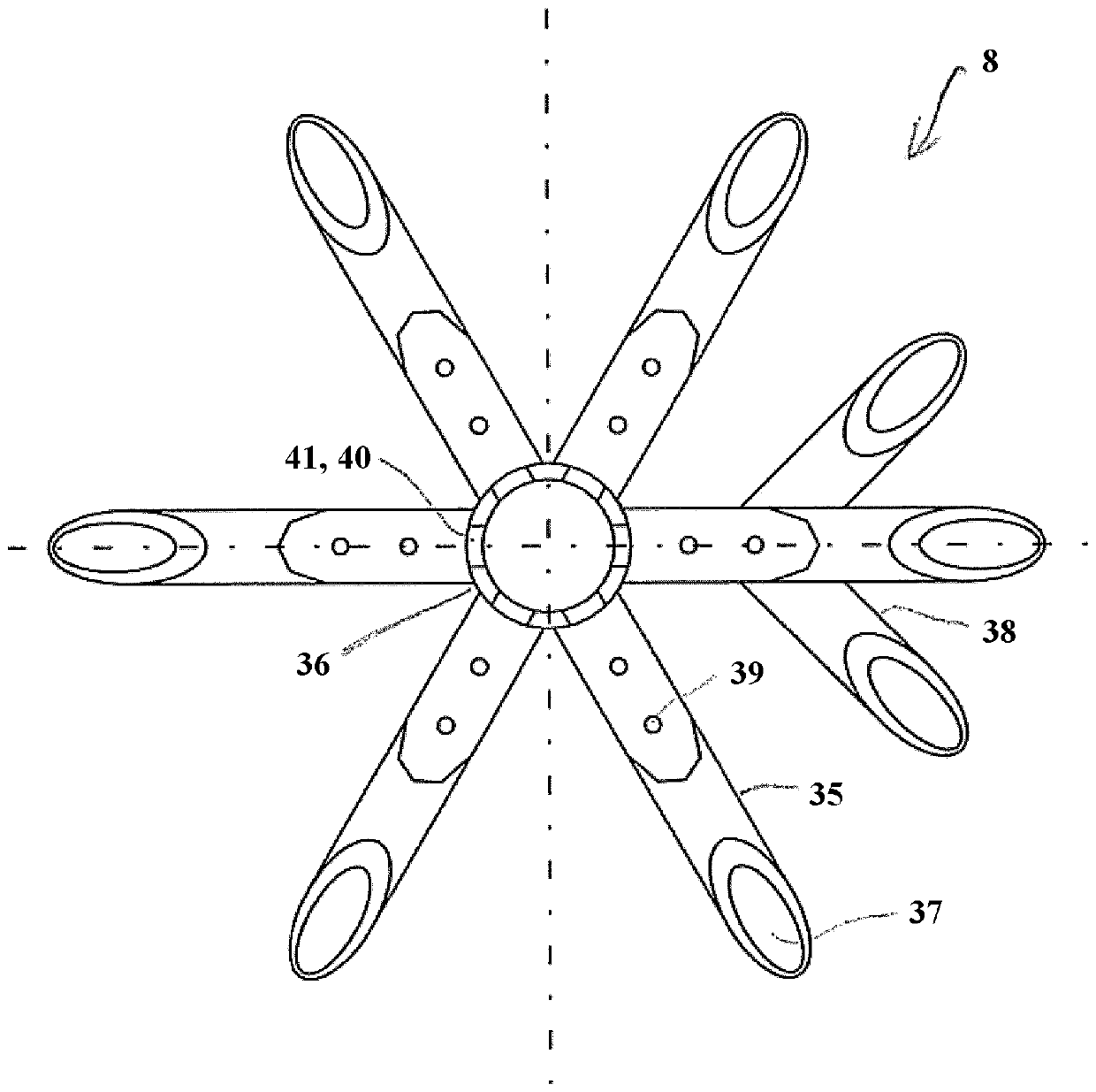

[0025] The illustrated embodiment of the tube bundle reactor 1 according to the invention has a reactor tube 3 bundle 2, a (not shown) gas inflow-side and gas outflow-side tube bottom 4, a reactor shell 5, ( (not shown) gas inflow-side and gas outflow-side reactor housing 6 and gas outflow chamber 7 with flow guiding device 8 .

[0026] The reaction tube 3 runs vertically and is represented by its tube axis 9 . For reasons of clarity only twelve reaction tubes 3 are shown. The actual number of reaction tubes 3 is much larger and may exceed 30,000.

[0027] During reactor operation, the reaction tubes 3 are filled with catalyst material and flowed through by a reaction gas 10 . In the illustrated embodiment, the reaction gas 10 flows from top to bottom.

[0028] The reaction tube 3 is welded with its ends in a sealing manner in a through-opening in the tube base 4 and leads into a (not shown) gas inflow chamber or into a gas outflow chamber 7 . In the illustrated embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com