Double beam design structure of gantry measuring machine combined with guide beam and load-bearing driving beam

A technology of guiding beams and driving beams, which is applied in the field of beam design and structure of gantry measuring machines, which can solve the problems of large-scale models that are difficult to implement and high cost, and achieve the effects of easy design and implementation, low precision requirements, and difficult implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

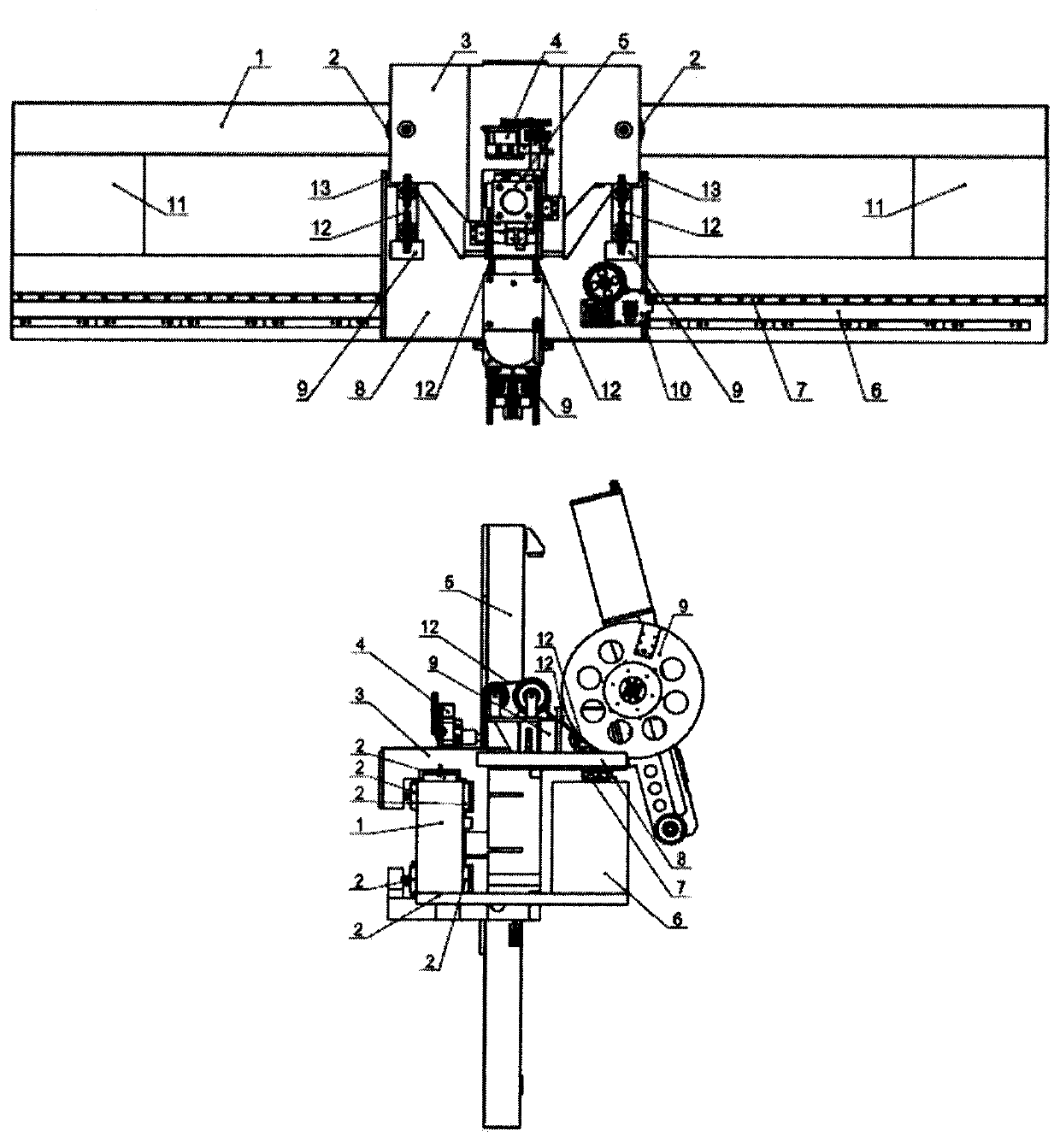

[0009] See attached figure 1 , a double-beam design structure of a gantry measuring machine combined with a guide beam and a load-bearing drive beam, including a guide beam, an air cushion, a YZ-axis carriage mechanically connected to the guide beam through an air cushion, and a Z-axis deceleration mechanically connected to the YZ-axis carriage Machine, Z-axis mechanically connected with YZ-axis carriage through air cushion, load-bearing drive beam, drive guide rail mechanically connected with load-bearing drive beam, drive seat mechanically connected with drive guide rail, counterweight mechanism mechanically connected with drive seat, and drive The Y-axis reducer is mechanically connected with the seat, and it also includes the X-axis sliding seat connecting plate and the steel wire rope. The guide beam (Y-axis) and Z-axis in the design structure are air-floating guide rail structures, and the driving guide rails are installed on the load-bearing drive beam in parallel with l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com