Adjustable flexible track device for pipeline

A flexible track and pipeline technology, applied in the direction of auxiliary devices, applications, tubular objects, etc., can solve the problems that the tightness of the track cannot be guaranteed, the track closing and connection operation is cumbersome, the spring cannot be adjusted, etc., and the operation is less. The effect of less, easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following examples illustrate possible implementations of the present invention, but are not intended to limit the protection scope of the present invention.

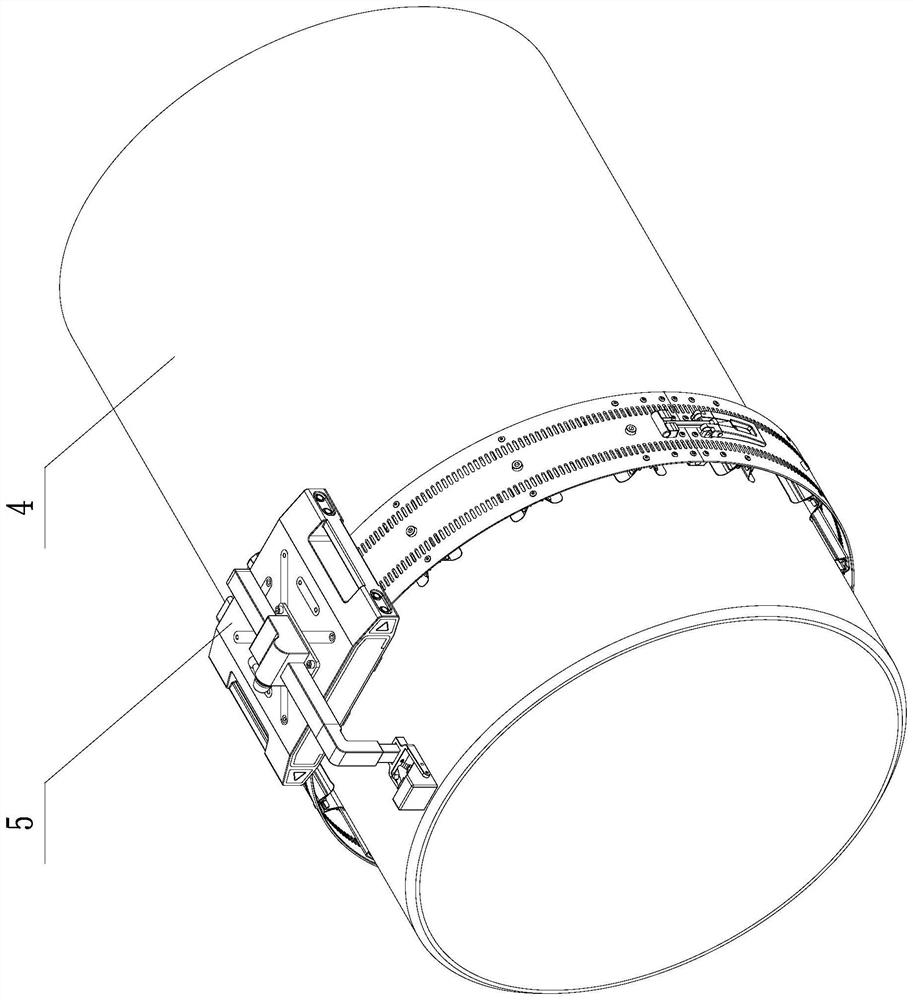

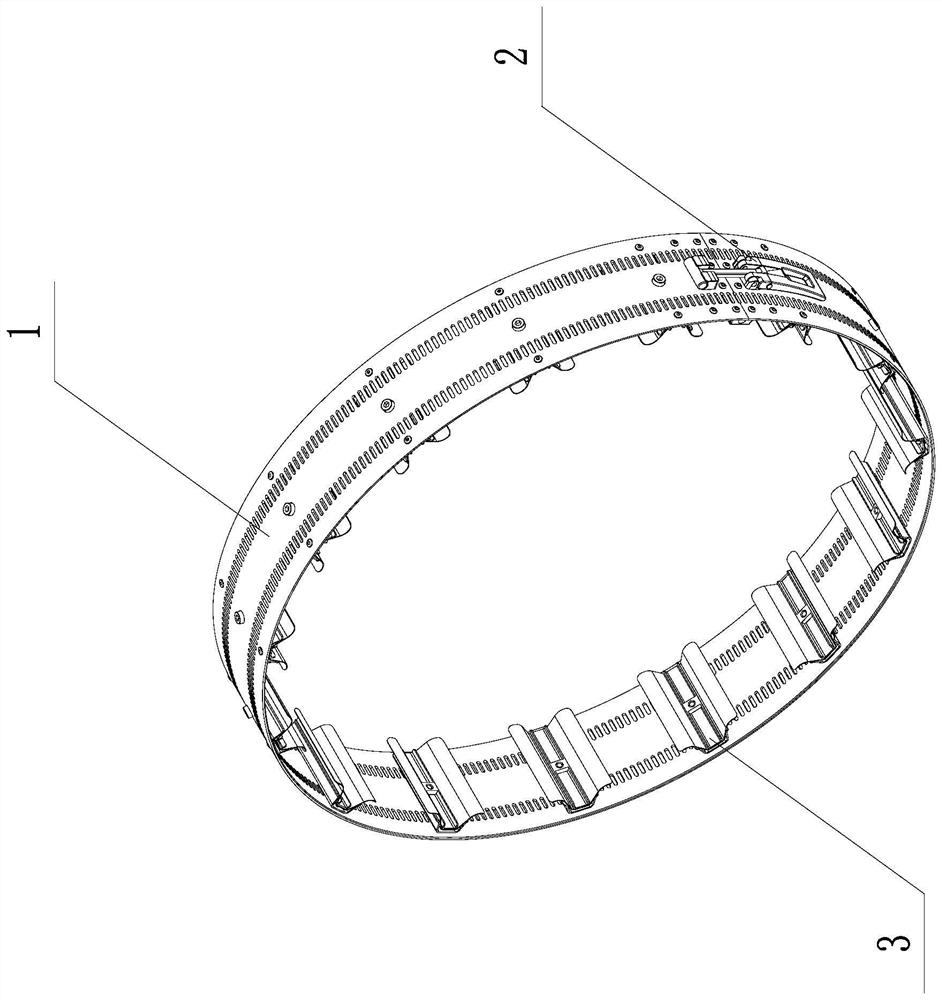

[0033] Such as Figure 1 to Figure 11 As shown, it is an adjustable flexible track device for a pipeline of the present invention, which includes a flexible track 1, a buckle assembly 2 and several double-stacked combined springs 3, and the two free ends of the flexible track 1 are butted through the buckle assembly 2, Several double-stacked combined springs 3 are evenly spaced on the inner ring of the flexible track, and the double-stacked combined springs 3 are adjustable on the pipe 4 .

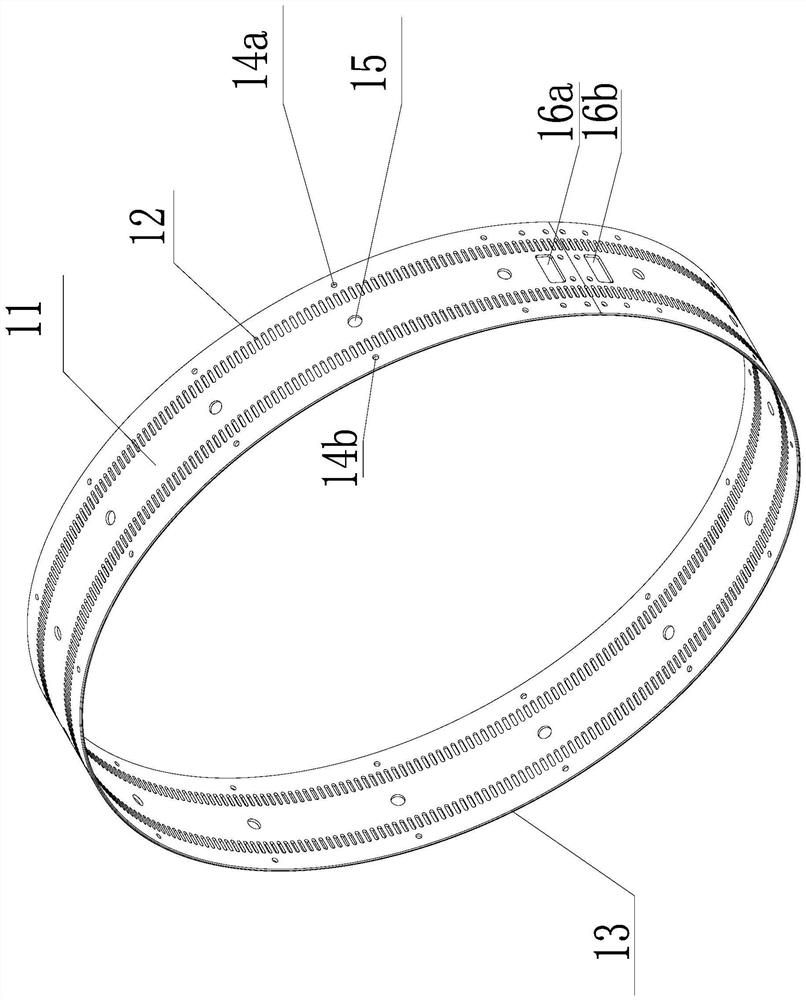

[0034] Such as image 3 As shown, the flexible track 1 includes a track ring 11, and a single row of cogs or multiple rows of cogs are opened on the track ring 11. In the present invention, two rows of cogs 12 corresponding to the interval are provided on the track ring. The four sharp edges on the side are provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com