Accuracy adjusting device for isothermal thermal forming hydraulic machine

A technology of warm forming and adjusting device, used in forging/pressing/hammer devices, forging/pressing/hammering machines, manufacturing tools, etc., can solve the problem that the workpiece cannot meet the design requirements, cannot meet the use requirements, and the forging accuracy is demanding. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

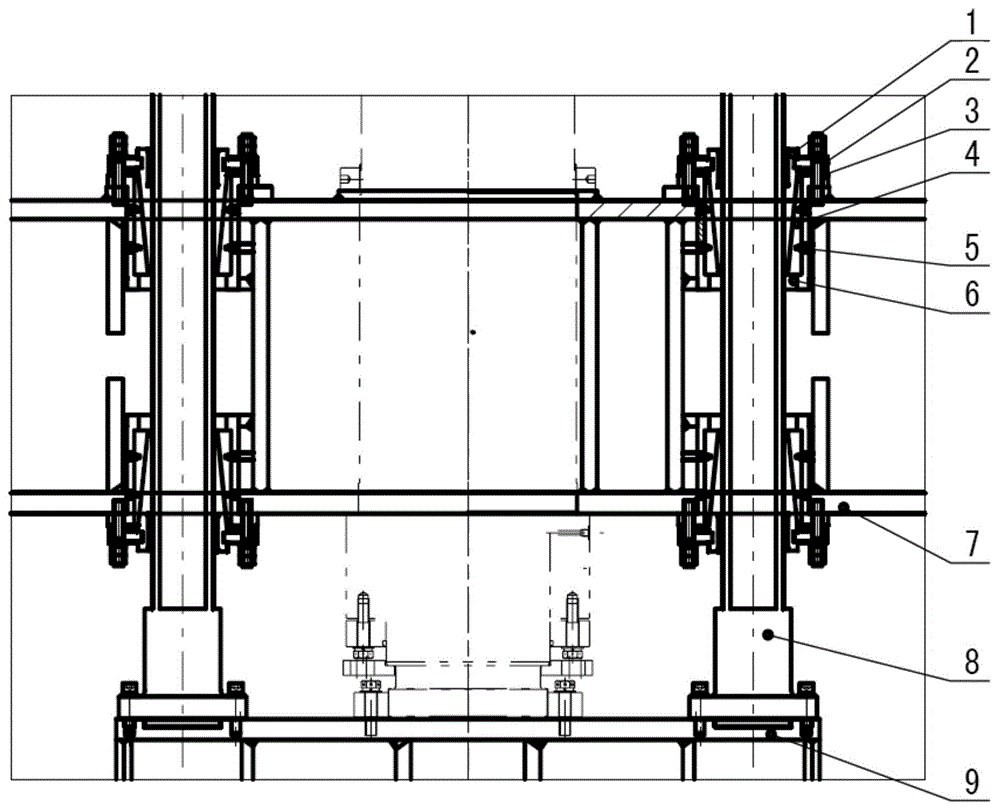

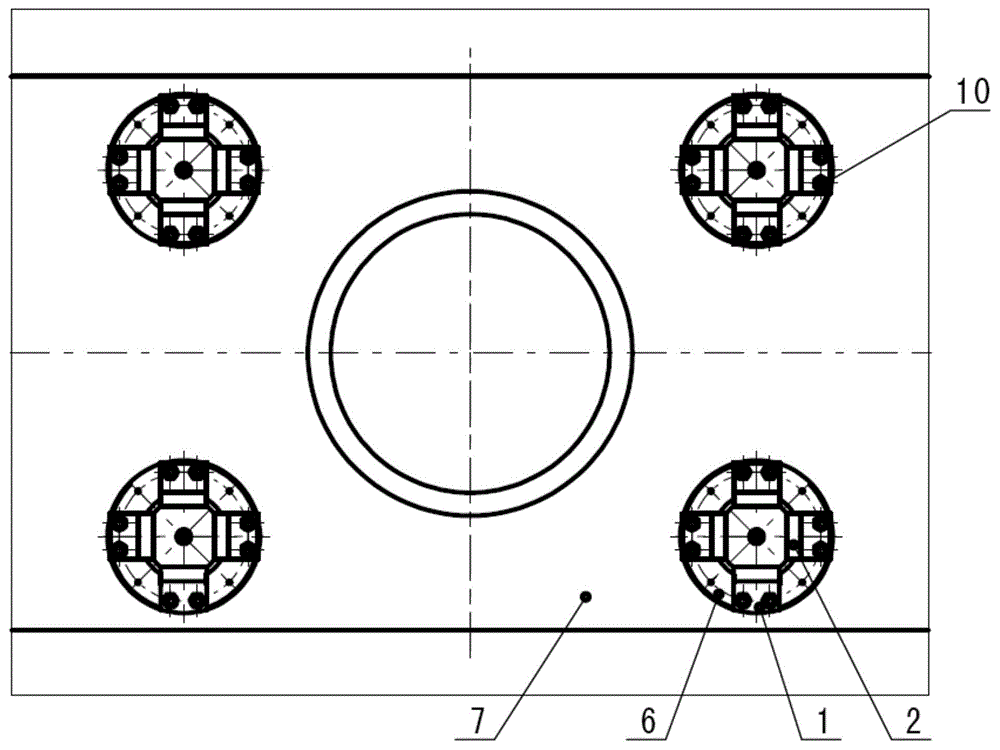

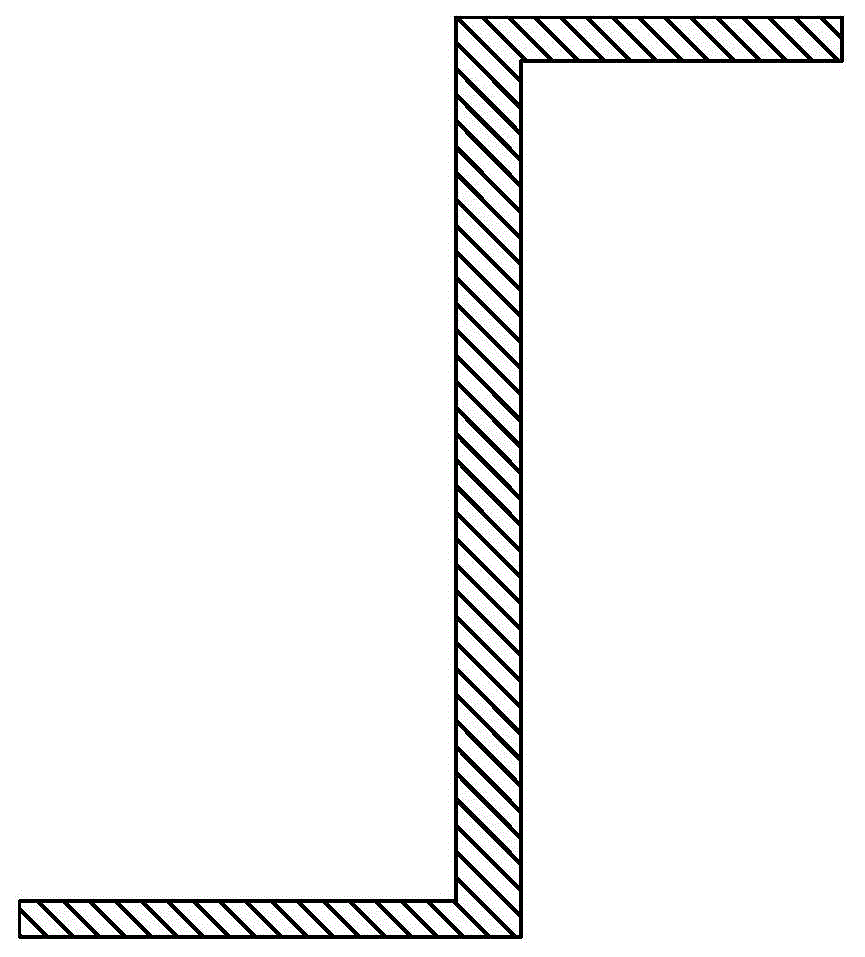

[0019] see figure 1 and figure 2 , a precision adjustment device for an isothermal thermoforming hydraulic press, the isothermal thermoforming hydraulic press includes four guide posts 8 fixed on a slider 9; the cross section of the guide posts 8 is square; There is an upper beam 7; a positioning sleeve 6 is arranged between the upper beam 7 and each guide column 8; please refer to image 3 : The positioning sleeve 6 is a "Z" structure with a corner of 90 degrees. One end of the positioning sleeve 6 is horizontally placed on the upper beam 7, and an adjustment pad 3 is placed on the horizontal lap surface of the positioning sleeve 6; the other end of the positioning sleeve 3 The end surface is in contact with the guide post 8, and the sliding wedge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com