Single-phase motor, fluid generation device and electrical equipment

A technology of single-phase motors and permanent magnets, which is applied in electromechanical devices, mechanical equipment, components of pumping devices for elastic fluids, etc., can solve problems such as large cogging effect, large vibration and noise, and reduce cogging effect, the effect of reducing the starting current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

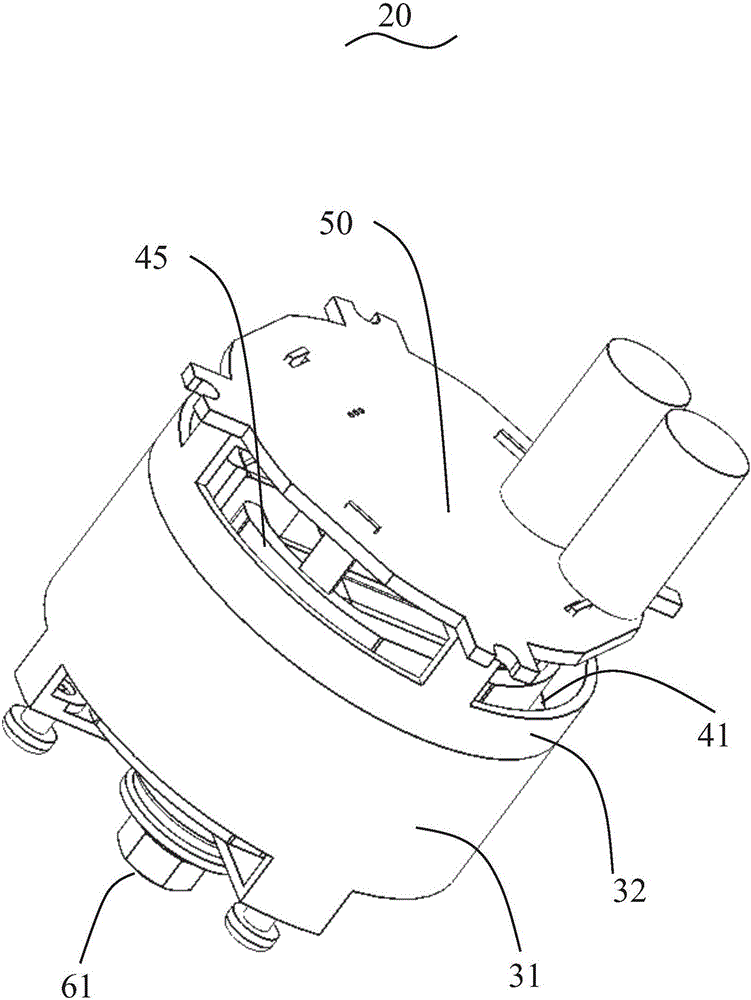

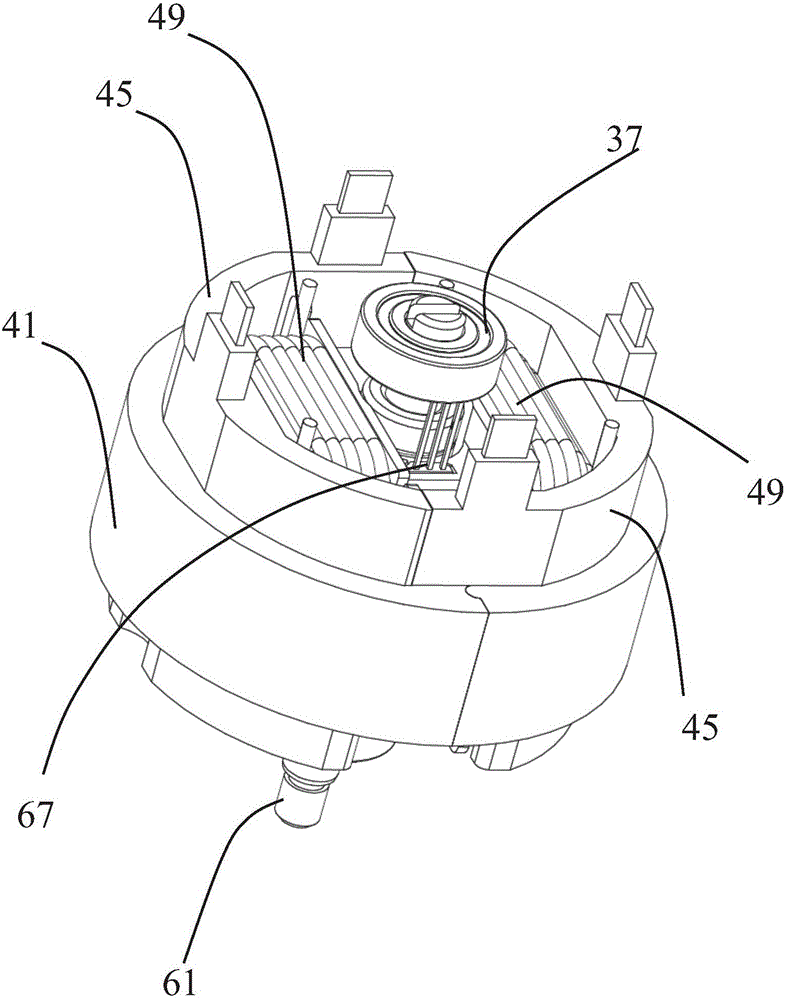

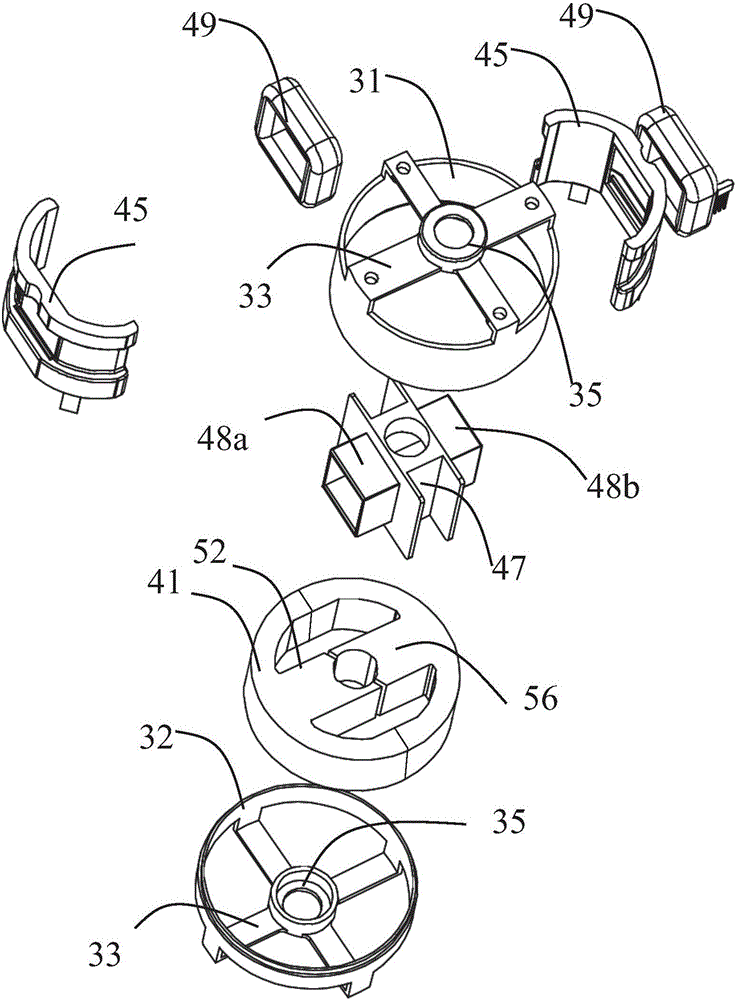

[0040] refer to Figure 1 to Figure 3 , the single-phase motor 20 provided by an embodiment of the present invention includes a stator and a rotor. The stator includes a stator casing, a stator magnetic core 41, a stator winding 49 wound on the stator magnetic core 41, and a control circuit board 50 mounted on one end of the stator. . The stator housing includes two half-shells 31 , 32 , each half-shell including an annular barrel, a hub 35 at the outer end of the barrel, and spokes 33 connected between the barrel and the hub 35 . A bearing 37 is installed in the hub portion 35, and the stator core 41 is made of magnetically conductive material such as iron, and is installed on the inner wall of the cylinder. In this embodiment, the single-phase motor 20 is a single-phase permanent magnet brushless DC motor 20. In other embodiments, the single-phase motor 20 can also be used as a permanent magnet synchronous motor.

[0041] The rotor includes a rotating shaft 61 and a perman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com