Rapidly-cooling pressure cooking appliance

A technology for rapid cooling and cooking utensils, applied to pressure cookers, etc., can solve the problems of water leakage, insufficient safety, inconvenient disassembly and cleaning of the inner cover of the pot cover, etc., to achieve convenient use, improve cooking efficiency, and shorten the time to open the pot cover the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

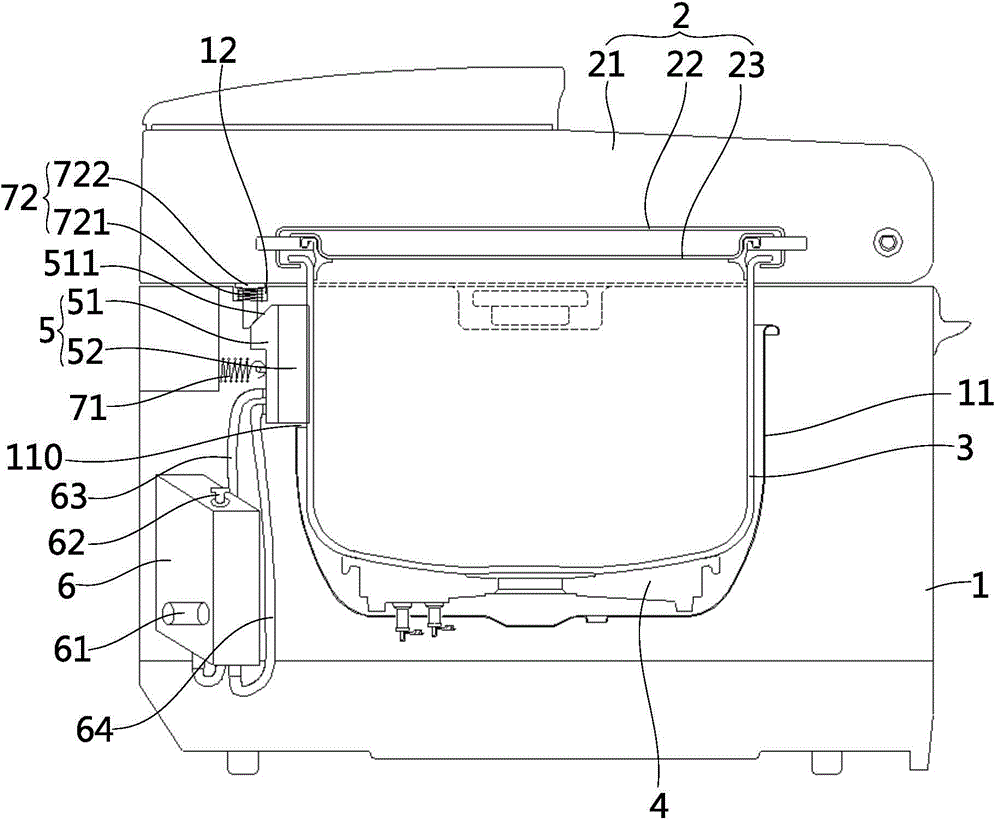

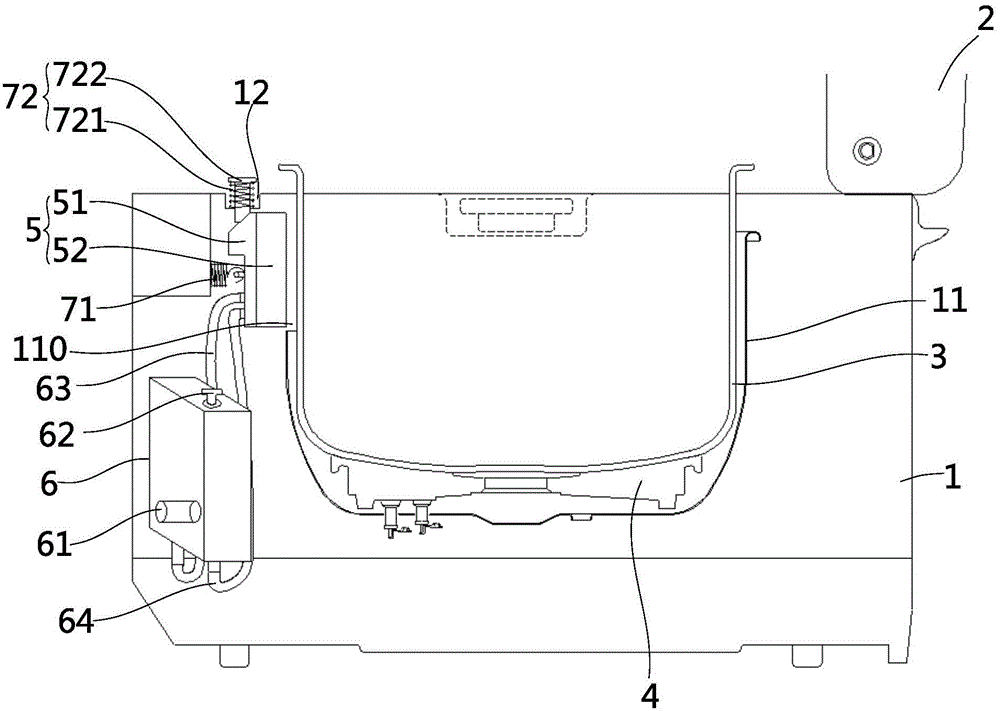

[0034] refer to figure 1 , 2 , the pressure cooking appliance of the embodiment of the present invention includes a body 1, a cover body 2 and an inner pot 3, the body 1 includes an outer pot 11, the inner pot 3 is accommodated in the outer pot 11 and can be taken out from the outer pot 11, and the cover body 2 It is hingedly connected to the body 1, and the cover body 2 can be flipped around its hinge. Specifically: in the pressure cooking appliance described in this embodiment, the cover body 2 includes an outer cover 21, an inner cover 23, and a lock ring 22 arranged between the outer cover 21 and the inner cover 23 and which can rotate relative to the inner cover 23. The ring 22 is provided with a first locking tooth, and the edge of the inner pot 3 is provided with a second locking tooth. When the cover body 2 is flipped and closed, rotating the locking ring 22 can make the first locking tooth and the second locking tooth snap together. The inner cover 23 is sealed with...

Embodiment 2

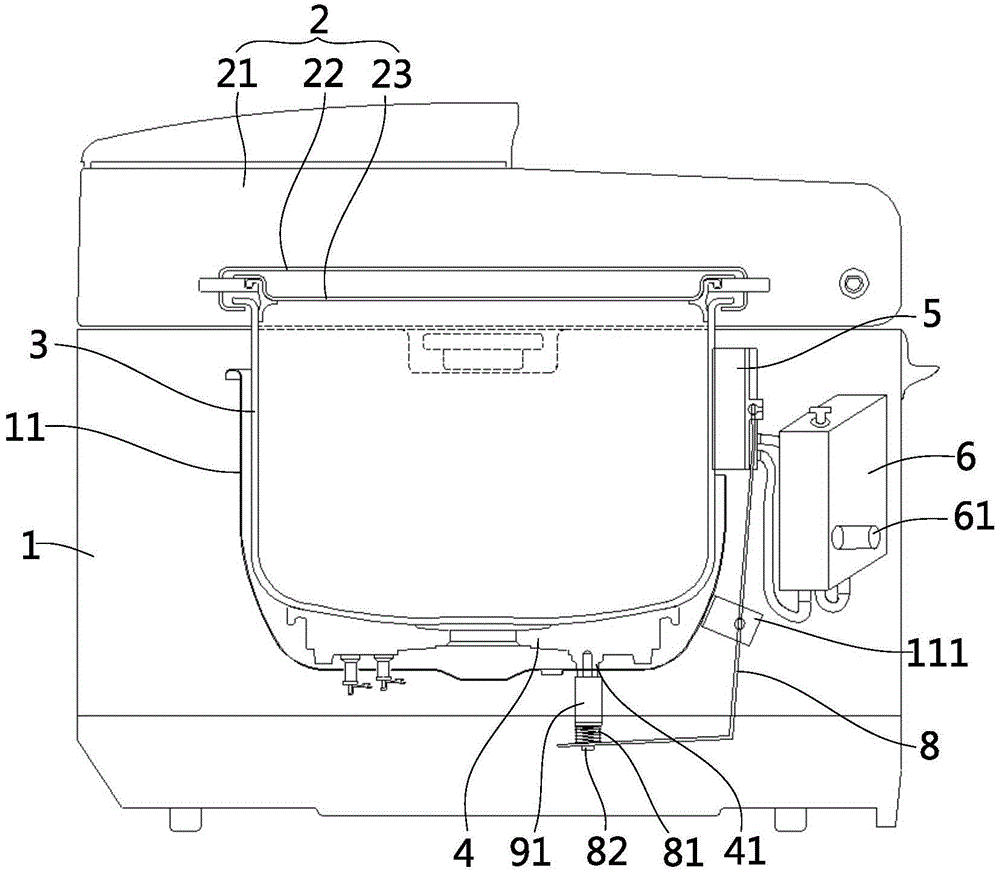

[0051] refer to image 3 The pressure cooking appliance proposed in this embodiment includes a body 1, a cover body 2 and an inner pot 3, the body 1 includes an outer pot 11, the inner pot 3 is accommodated in the outer pot 11 and can be taken out from the outer pot 11, and the cover body 2 It is hingedly connected to the body 1, and the cover body 2 can be flipped around its hinge. Specifically: in the pressure cooking appliance described in this embodiment, the cover body 2 includes an outer cover 21, an inner cover 23, and a lock ring 22 arranged between the outer cover 21 and the inner cover 23 and which can rotate relative to the inner cover 23. The ring 22 is provided with a first locking tooth, and the edge of the inner pot 3 is provided with a second locking tooth. When the cover body 2 is flipped and closed, rotating the locking ring 22 can make the first locking tooth and the second locking tooth snap together. The inner cover 23 is sealed with the inner pot 3 to fo...

Embodiment 3

[0057] refer to Figure 4 , 5 The pressure cooking appliance proposed in this embodiment includes a body 1, a cover body 2 and an inner pot 3, the body 1 includes an outer pot 11, the inner pot 3 is accommodated in the outer pot 11 and can be taken out from the outer pot 11, and the cover body 2 It is hingedly connected to the body 1, and the cover body 2 can be flipped around its hinge. Specifically: in the pressure cooking appliance described in this embodiment, the cover body 2 includes an outer cover 21, an inner cover 23, and a lock ring 22 arranged between the outer cover 21 and the inner cover 23 and which can rotate relative to the inner cover 23. The ring 22 is provided with a first locking tooth, and the edge of the inner pot 3 is provided with a second locking tooth. When the cover body 2 is flipped and closed, rotating the locking ring 22 can make the first locking tooth and the second locking tooth snap together. The inner cover 23 is sealed with the inner pot 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com