Manufacturing method of guide plate for complete denture implantation

A production method and a technology of complete dentures, which are applied in the fields of implantology, medical science, and dentistry, can solve the problems of inconvenient operation, long design time, and easy fracture, etc., and achieve shortened operation time, accurate implant surgery plan, pain relieving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

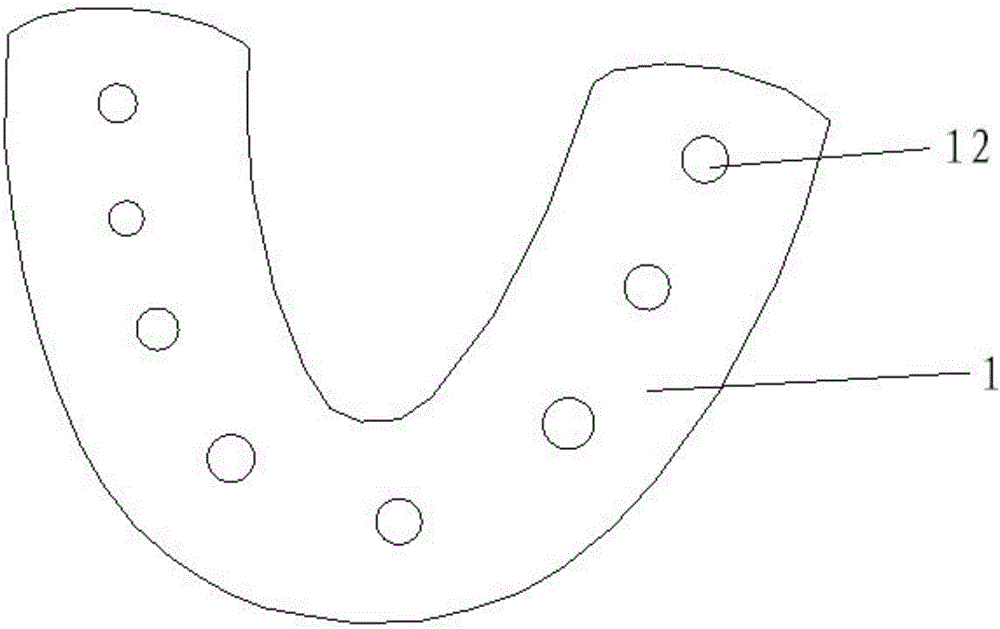

[0017] figure 1 As shown, it relates to a guide plate for complete denture implantation. Polycaprolactone material is injected through a molding mold to form a general oral alveolar bone profile 1, and a plurality of positioning holes 12 are opened on the surface along the direction of the alveolar.

[0018] The specific production method is as follows:

[0019] (1) Add polycaprolactone material into the polycaprolactone forming mold, control the heating temperature at 62-68 degrees Celsius, and compact the material by extrusion when the polycaprolactone material softens to form the required shape , take it out after waiting for cooling, and make it into the preparation material for the planting guide plate;

[0020] (2) Carry out simulated implantation on the patient's dental model to form the implantation position;

[0021] (3) transfer rod is put into the planting guide plate preparation material that step (1) makes;

[0022] (4) Put the preparation material for the plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com