A kind of automatic paper shredder and automatic shredding method

A paper shredder and automatic paper feeding technology, applied in grain processing and other directions, can solve the problems of poor structural strength, large space occupation and low reliability of the automatic paper feeding device, optimize and manual paper feeding channels, reduce The effect of paper jam rate and improving paper shredding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

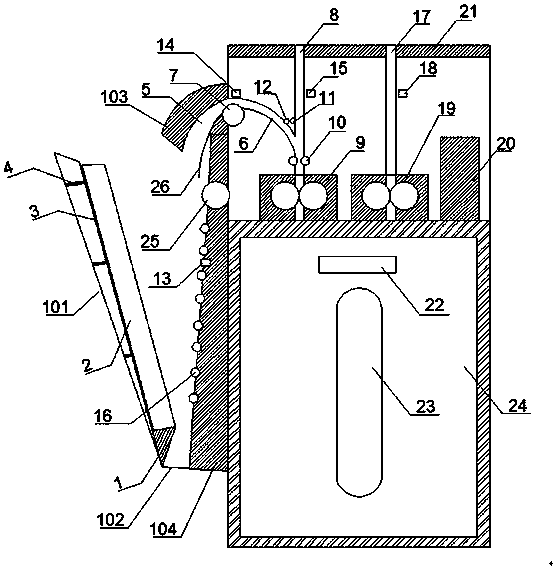

[0041] Such as figure 2 as shown, figure 2 An automatic paper feeding shredder is described, including a manual paper feeding channel 8, a third paper sensor 15 for detecting whether there is waste paper in the manual feeding channel 8, a paper shredder 9, and a drive roller (including The driver 20 and the shredded paper storage box 24 for the work of the paper feed roller, pressure roller, guide roller, etc.) described in this application, the paper shredder also includes: the waste paper storage box 1 and Arc-shaped second automatic paper feeding passage 6.

[0042] The waste paper storage box 1 is mainly composed of a movable part 101, a bottom 102, a top 103 and a fixed part 104, wherein: the movable part 101 includes a waste paper storage area 2 for storing waste paper to be shredded and a tight top The top board 3 and the elastic member 4 of the waste paper in the waste paper placement area 2, the elastic member 4 enables the top board 3 to move in the waste paper p...

Embodiment 2

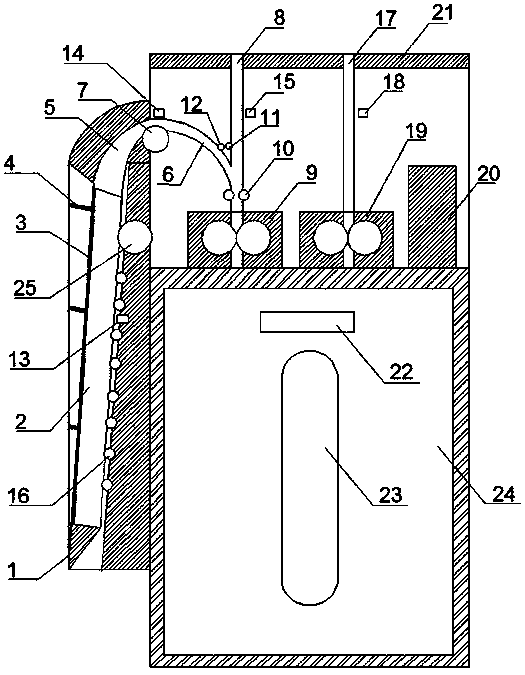

[0056] The second embodiment is a further improvement on the basis of the solution of the first embodiment of a waste paper storage box-mounted automatic paper-feeding shredder. In the second embodiment, the waste paper storage box 1 is connected to the side wall of the shredder body through the connecting piece provided on the outer wall of the fixing part 104 . The paper shredder proposed in the second embodiment is designed in an external form, which is beneficial for subsequent maintenance or upgrading, and is beneficial for dealing with paper jams in the automatic paper feeding channel.

[0057] In the second embodiment, the first automatic paper feeding channel 5 and the second automatic paper feeding channel 6 are independent non-integrated structures, and the connecting points thereof need to be set to match each other.

[0058] Further, in the second embodiment, a locking device for firmly connecting the waste paper storage box 1 with the shredder body can also be pro...

Embodiment 3

[0060] A built-in waste paper storage box automatic paper shredder, the third embodiment is a further improvement on the basis of the first embodiment. Such as Figure 4 As shown, in the third embodiment, the waste paper storage box 1 is arranged inside the shredder, and the first automatic paper feeding channel 5 and the second automatic paper feeding channel 6 can be integrated or independently matched.

[0061] Based on the third embodiment, the paper shredder has an integral structure, which is convenient for appearance design, more beautiful, optimizes the occupied space, and is also convenient for packaging and transportation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com