Rotary cleaning device for wallboard

A technology for cleaning devices and wallboards, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of inconvenient flipping of boards, high maintenance costs of devices, time-consuming and labor-intensive problems, and achieve novelty Strong durability, low maintenance cost and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

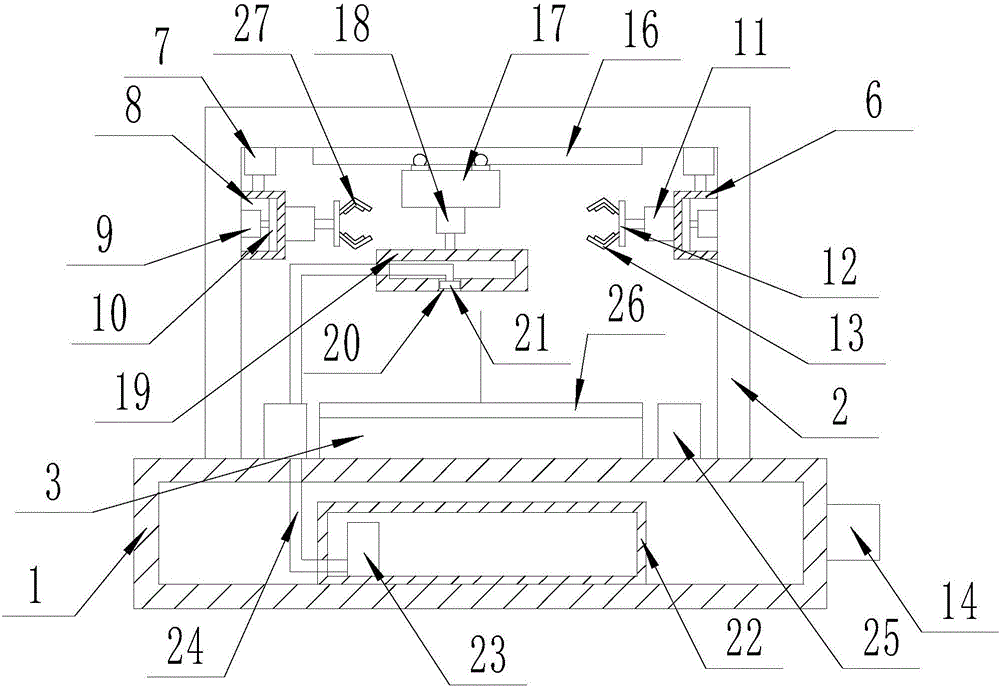

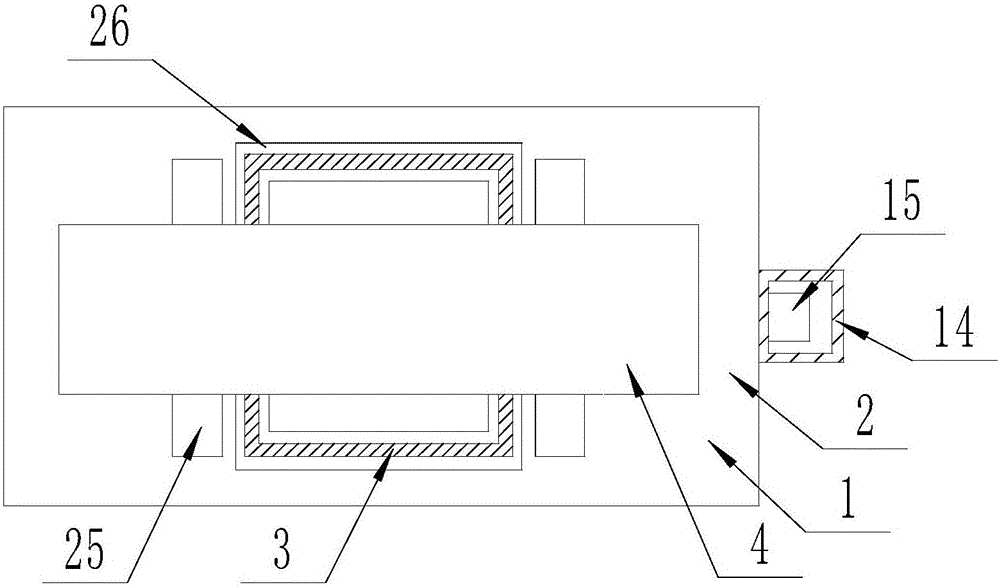

[0014] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, a wallboard rotary cleaning device includes a workbench (1), the inside of the workbench (1) is a cavity structure, and the upper surface of the workbench (1) is provided with a gantry (2), the A rectangular support frame (3) is provided below the gantry (2) and at the center of the upper surface of the workbench (1), and a rectangular slideway (4) is processed on one side surface of the legs of the gantry (2). No. 1 slide rail (5) is provided in each rectangular slideway (4), and a slide block (6) is provided on each No. 1 slide rail (5). The surface is provided with a group of linear motors (7) with telescopic ends facing downwards, and the telescopic ends of each linear motor (7) are fixedly connected with each slider (6), and each slider (6) is processed There is a circular groove (8), and each of the circular grooves (8) is provided with a No. 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap