Dust collecting type negative pressure dust suction machine

A vacuum cleaner and negative pressure technology, which is applied in the field of air-conditioning cleaning equipment, can solve the problems of short service life of the filter screen and high maintenance cost of the vacuum cleaner, and achieve the effects of small air volume loss, increased filtering effect, and simple air path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

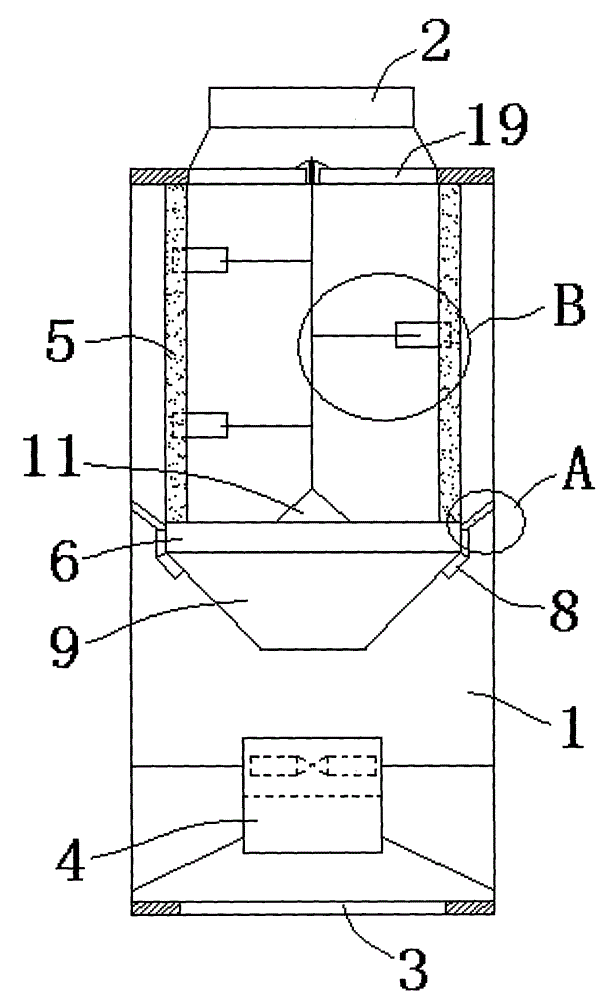

[0028] Such as figure 1 As shown, a dust-collecting negative pressure vacuum cleaner described in the embodiment of the present invention includes a chassis 1, the upper and lower sides of the chassis 1 are respectively provided with an air guide 2 and an air outlet 3, and the bottom of the chassis 1 An exhaust fan 4 is provided, and the gas enters from the air guide port 2, passes through the entire chassis 1, and is discharged from the air outlet 3.

[0029] The casing 1 is provided with a cylindrical filter element 5, the cylindrical filter element 5 corresponds to the air guide port 2, and forms an air inlet channel therewith, and a plurality of evenly distributed studs are arranged on the upper side of the cylindrical filter element 5 , the stud directly passes through the casing 1 and is fixed with a nut, so that the cylindrical filter element 5 can be detachably installed inside the casing 1, and the replacement is simple.

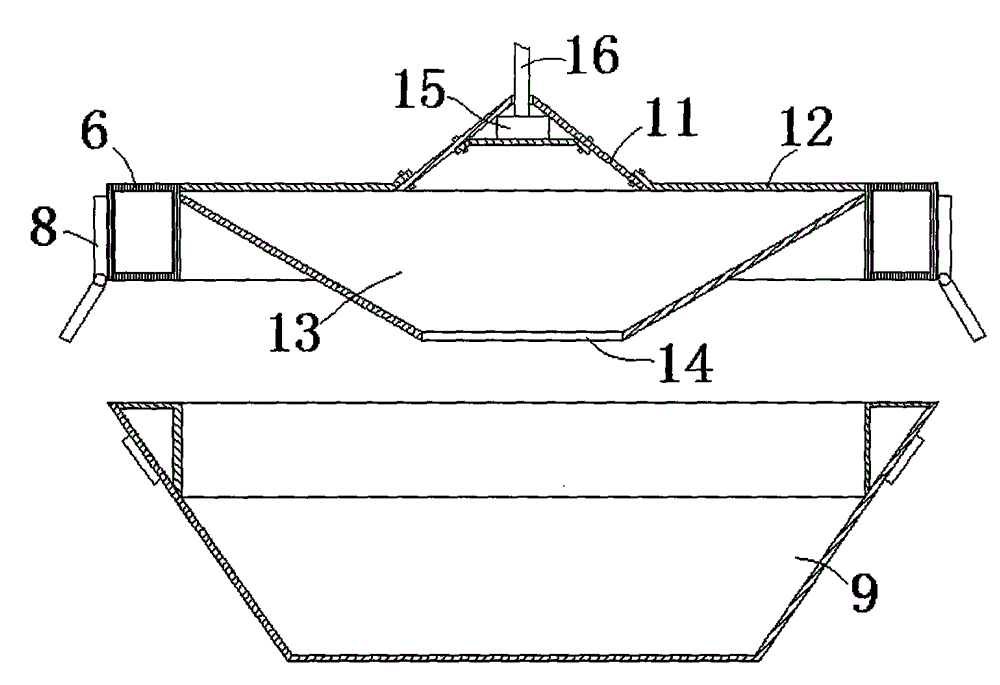

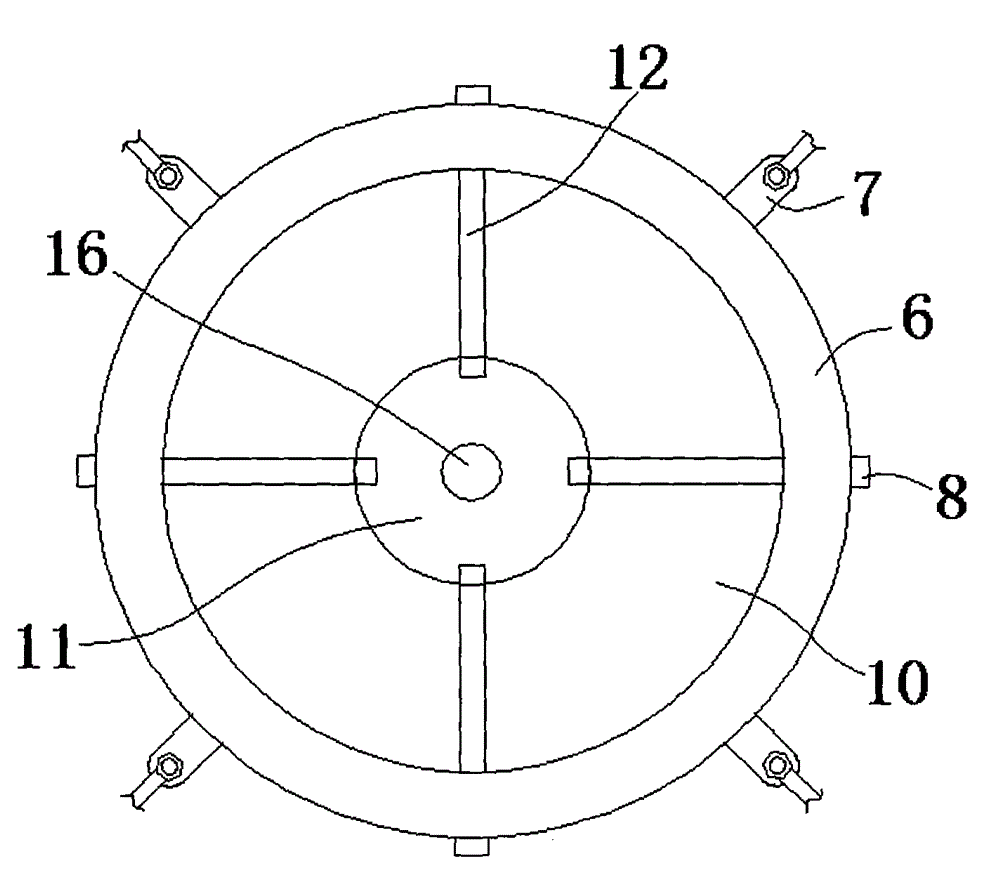

[0030] Such as Figure 2-3 As shown, the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com