A plastic shell of commutator Morgan mold is automatically pressed into the preheating mechanism

A commutator and automatic technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of cumbersome operation and lower work efficiency, and achieve the effect of convenient operation, high work efficiency and stable work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings:

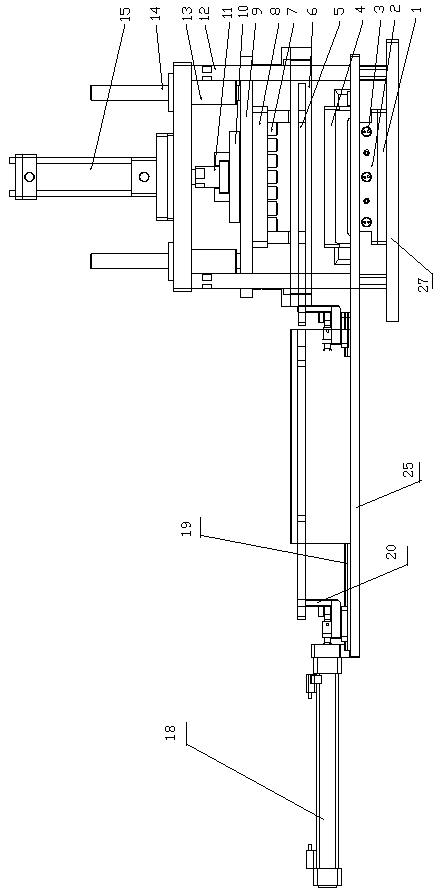

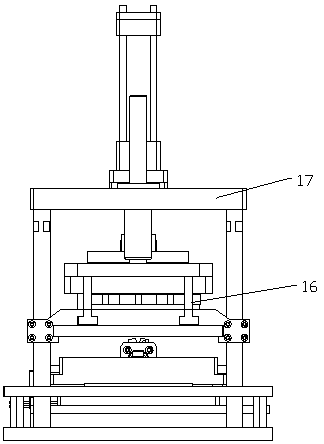

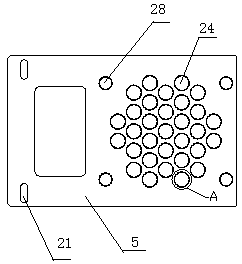

[0018] As shown in the figure, a plastic shell of a commutator Morgan mold is automatically pressed into the preheating mechanism, which is provided with a middle template 4, which is characterized in that the preheating mechanism consists of a transition plate 5, a transition plate transfer assembly and a press-in preheating The transition plate 5 is provided with a positioning port 21 for pushing the transition plate and a positioning hole 24 for positioning and transporting the plastic case. The transition plate moving assembly is composed of a transport cylinder 18, a transition plate support plate 25, The linear guide rail 19, the push block 20, the guide rail 22 and the floating guide rail 23 are composed. The output shaft of the conveying cylinder 18 is connected with the push block 20. The transition plate support plate 25 is provided with a linear guide 19, and the push block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com