Closed die forging die and closed die forging method

A technology of die forging and occlusion, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of complex shape, large deformation, large forging volume, etc., and reduce production costs , The effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

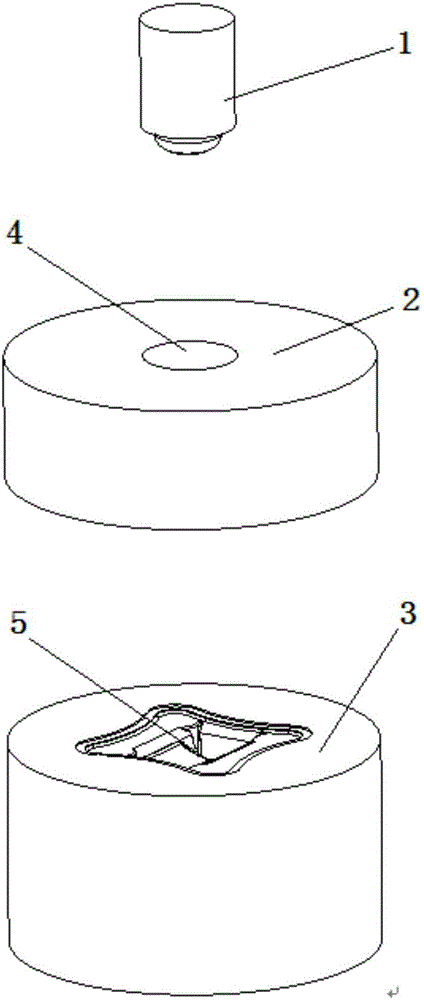

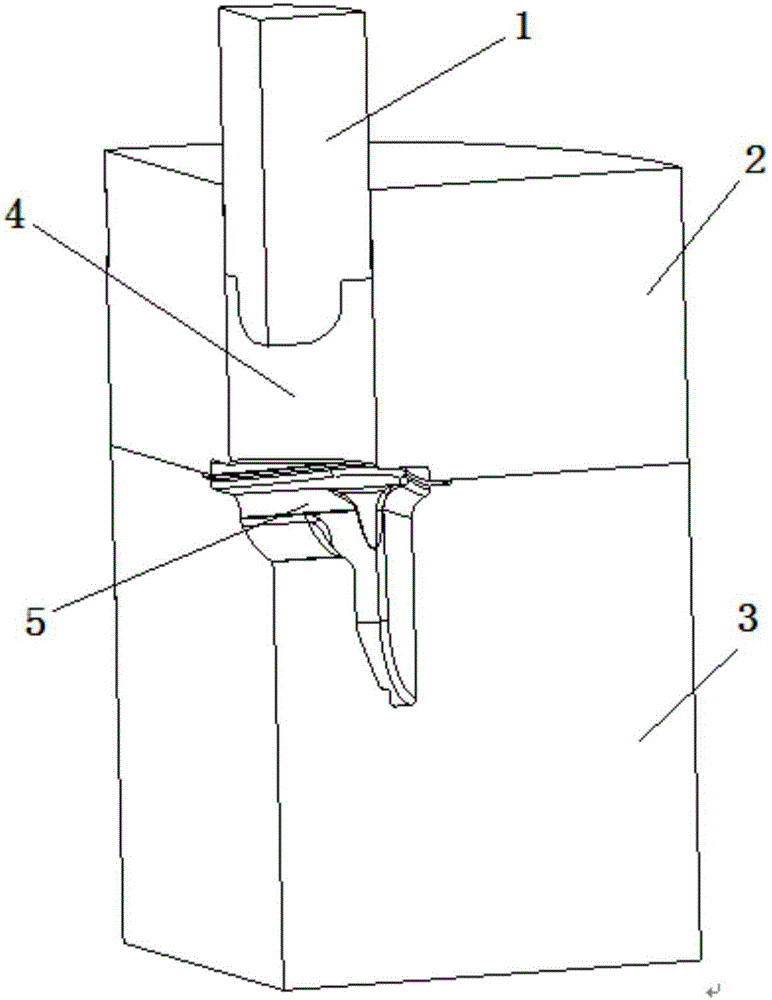

[0021] Such as figure 1 , figure 2 , image 3 , is a schematic diagram of a closed die forging die for a joint flange (also known as "flange fork"), including an upper die 2 and a lower die 3, and the upper die 2 is provided with a barrel 4 and a punch 1. The punch The rod 1 extends into the barrel 4 .

[0022] The die forging method of the joint flange is as follows:

[0023] Step a: heating the blank, opening the closed forging die, and putting the blank into the cavity of the closed forging die;

[0024] Step b: Close the upper mold 2 and the lower mold 3, and lock the upper mold 2 and the lower mold 3;

[0025] Step C: the punch rod 1 is punched down in the barrel 4, so that the blank fills the entire die cavity;

[0026] Step D: Open the closed forging die after the blank is formed by die forging, and take out the forging.

[0027] After forging, trimming, shot blasting, cold finishing, turning and other processes can also be carried out.

Embodiment 2

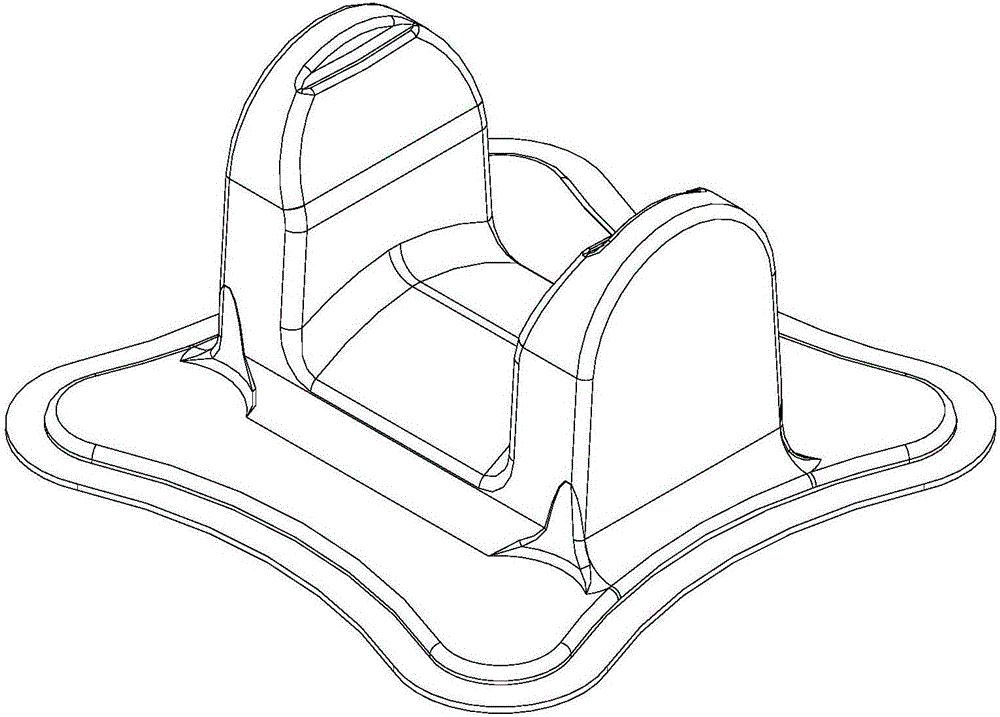

[0029] Such as Figure 4 , Figure 5 , is a schematic diagram of a closed die forging die for a triangular flange, and its basic structure is the same as in Example 1 except that the cavity shape is different from that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com