Tundish for preparing iron-nickel soft magnetic alloy powder by water atomization and manufacturing method thereof

An iron-nickel soft magnetic alloy and tundish technology, applied in the field of powder metallurgy, can solve problems such as unusable, high production cost, and discarding of leaked sacks, and achieve the effects of prolonging service life, eliminating molten steel foam, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

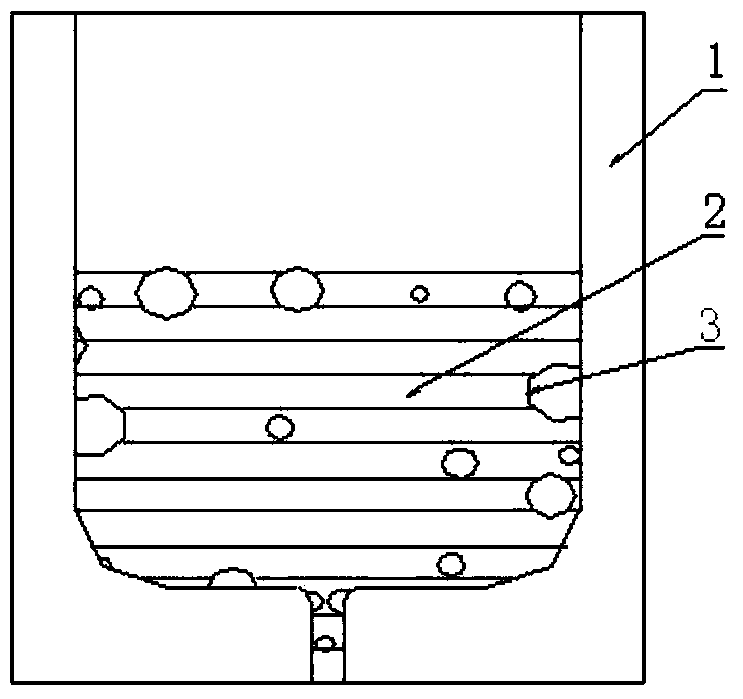

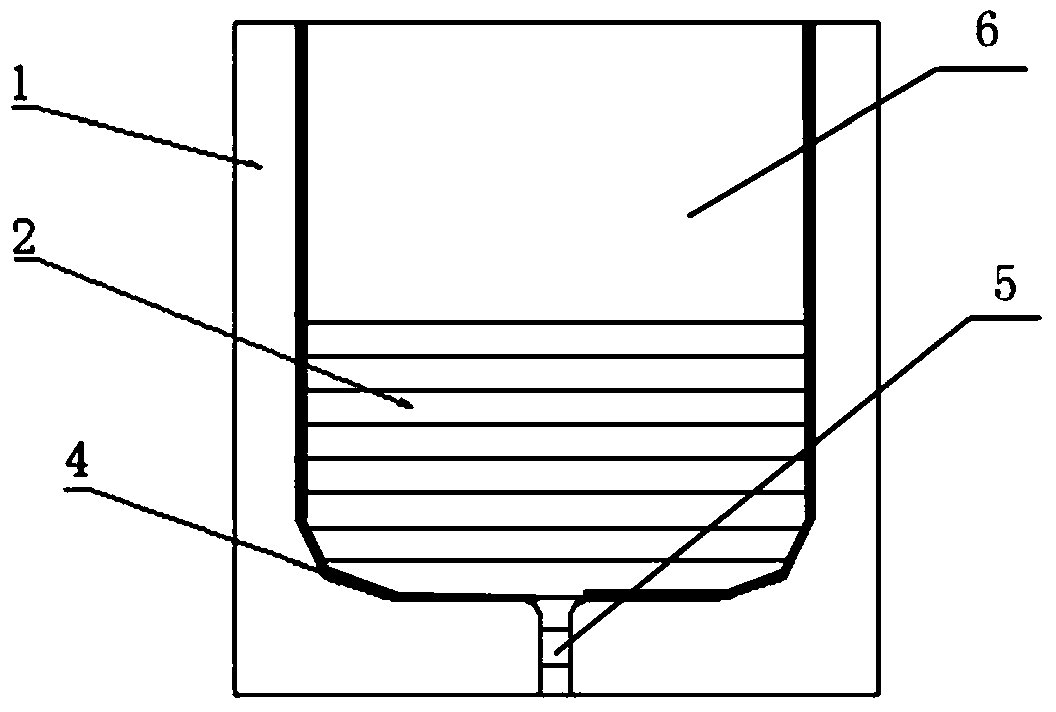

[0032] The tundish of this embodiment includes: a tundish body 1, which is formed with an alloy liquid container 6 for containing the molten alloy liquid 2; a liquid leakage hole 5 is provided on the bottom surface of the tundish body 1, and is used for setting a leakage hole 5; eye device. The tundish body 1 is made of graphite clay; the protective coating 4 is arranged on the inner wall of the tundish body 1 (the inner wall includes a side wall and a bottom wall), and is used to prevent the molten alloy liquid 2 from contacting the inner wall of the tundish body 1. Chemical reaction and erosion occur, and the protective coating 4 is a magnesium oxide coating, and the thickness of the coating is about 6mm. The tundish body 1 also includes a leaking device (not shown in the figure) arranged at the leak hole 5, so that the alloy liquid in the tundish body falls at a prescribed speed, and the leaking device can be purchased from the market as required, and its The flow rate of ...

Embodiment 2

[0039] The tundish of this embodiment includes: a tundish body 1, which is formed with an alloy liquid container 6 for containing the molten alloy liquid 2; a liquid leakage hole 5 is provided on the bottom surface of the tundish body 1, and is used for setting a leakage hole 5; eye device. The tundish body 1 is made of graphite clay; the protective coating 4 is arranged on the inner wall of the tundish body 1 (the inner wall includes a side wall and a bottom wall), and is used to prevent the molten alloy liquid 2 from contacting the inner wall of the tundish body 1. Chemical reaction and erosion occur, and the protective coating 4 is a magnesium oxide coating with a coating thickness of about 3 mm. The tundish body 1 also includes a leaking device (not shown in the figure) arranged at the leak hole 5, so that the alloy liquid in the tundish body falls at a prescribed speed, and the leaking device can be purchased from the market as required, and its The flow rate of alloy li...

Embodiment 3

[0046] The tundish of this embodiment includes: a tundish body 1, which is formed with an alloy liquid container 6 for containing the molten alloy liquid 2; a liquid leakage hole 5 is provided on the bottom surface of the tundish body 1, and is used for setting a leakage hole 5; eye device. The tundish body 1 is made of graphite clay; the protective coating 4 is arranged on the inner wall of the tundish body 1 (the inner wall includes a side wall and a bottom wall), and is used to prevent the molten alloy liquid 2 from contacting the inner wall of the tundish body 1. Chemical reaction and erosion occur, and the protective coating 4 is a magnesium oxide coating, and the thickness of the coating is about 6mm. The tundish body 1 also includes a leaking device (not shown in the figure) arranged at the leak hole 5, so that the alloy liquid in the tundish body falls at a prescribed speed, and the leaking device can be purchased from the market as required, and its The flow rate of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com