Machining device for push-pull door and window aluminum profile

A technology of sliding doors and windows and processing devices, which is applied in the direction of sawing machine devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of flying chips, low safety performance, and low machining accuracy of sawing machines, so as to avoid splashing everywhere, The effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

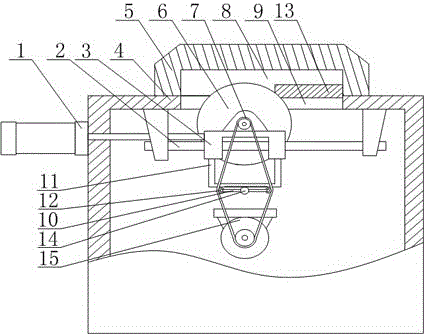

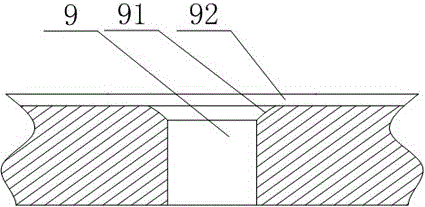

[0022] Such as figure 1 with figure 2 As shown, this embodiment includes a housing 4 and a cover body 5 installed on the upper end of the housing 4, the two ends of the cover body 5 are respectively provided with an inlet and an outlet, and the housing 4 is sequentially provided with Guide rod 2 and motor 15, slide block 3 is sleeved on guide rod 2, and saw blade 6 is installed on slide block 3, and the rotating shaft of described saw blade 6 is connected with the output end of motor 15 by belt 7, and in housing 4. A cylinder 1 is installed on the side wall. The output end of the cylinder 1 moves through the outer wall of the housing 4 and then connects with the side wall of the slider 3. A cutting hole 9 parallel to the guide rod 2 is opened on the upper surface of the housing 4. Saw The upper part of the sheet 6 runs through the cutting hole 9, and a cavity 8 facing the cutting hole 9 is opened in the cover body 5; a rotating rod 14 perpendicular to the guide rod 2 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com