Plastic mold rapid processing equipment

A technology for plastic molds and processing equipment, applied in the field of rapid processing equipment for plastic molds, can solve the problems that plastic mold processing equipment cannot be processed automatically, and achieve the effects of simple structure, convenient operation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with embodiment.

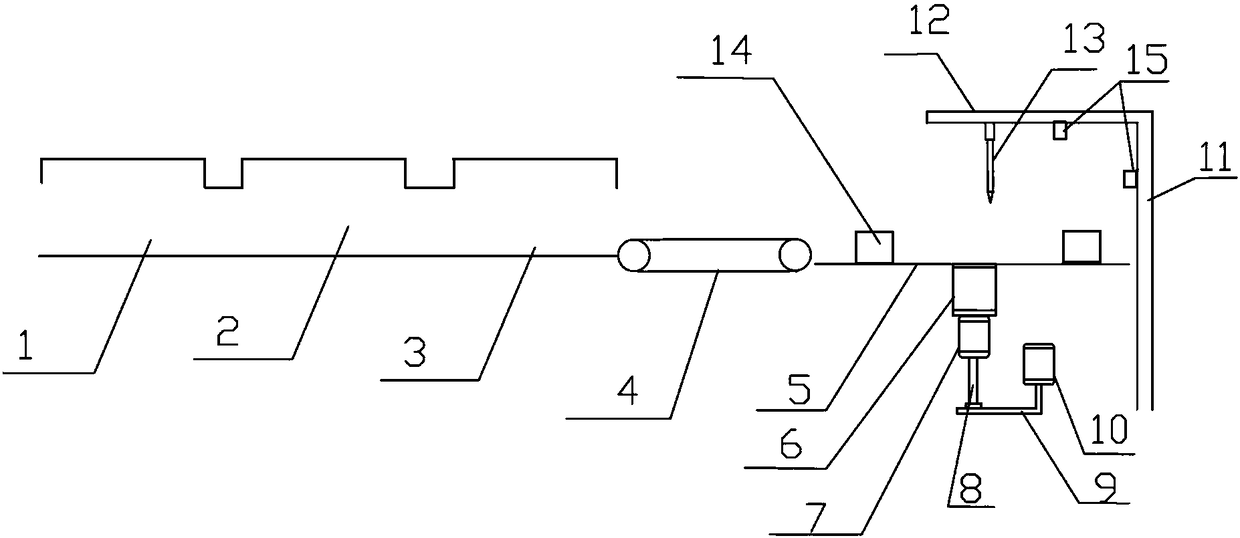

[0018] Plastic mold rapid processing equipment, such as figure 1 As shown, it includes model area 1, frosting area 2, cooling area 3, transfer table 4, processing platform 5, telescopic shaft 6, vertical motor 7, support rod 8, ring rod 9, horizontal motor 10, vertical rod 11, Cross bar 12, engraving drill bit 13, two fixed blocks 14 and light detector 15. Model area 1 is mainly for the formation of the approximate shape of the mold, and also includes a frosted part and a cooling part. The frosted part mainly grinds the newly formed model to obtain a smooth appearance. The cooling part mainly cools down the newly formed model for the next step of processing. prepare.

[0019] The model area 1 is connected with one end of the frosting area 2; the other end of the frosting area 2 is connected with the cooling area 3; the other end of the cooling area 3 is arranged at one end of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com