Detachable steel core die and method for manufacturing prestress concrete hollow beam

A technology of steel core and the other side, applied in the direction of joists, girders, trusses, etc., can solve the problems of not disclosing the specific structure of the abrasive tool, inconvenient disassembly of the mold, etc., to improve the fullness and compactness, and improve durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

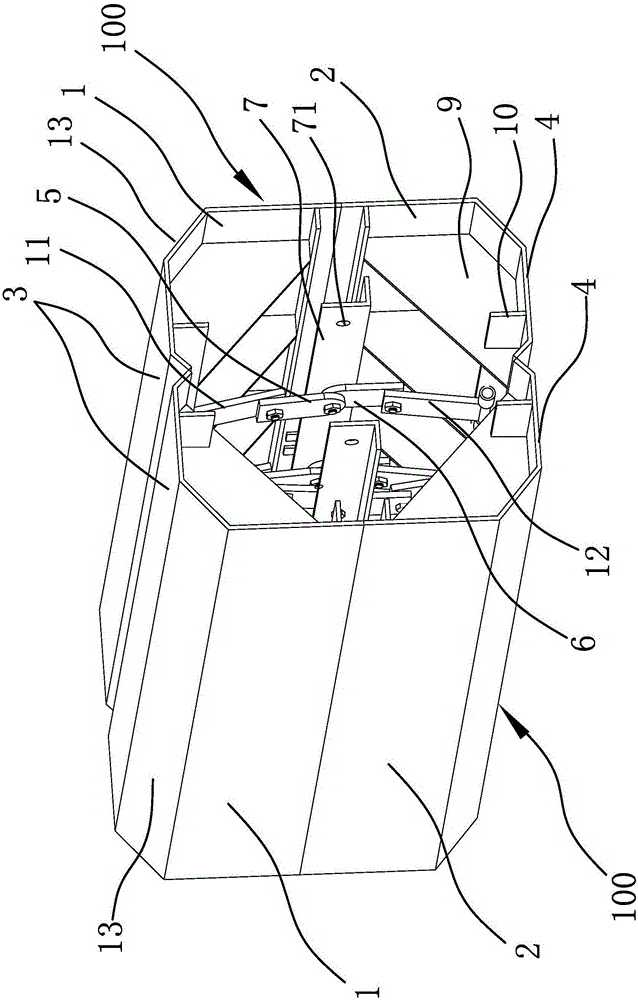

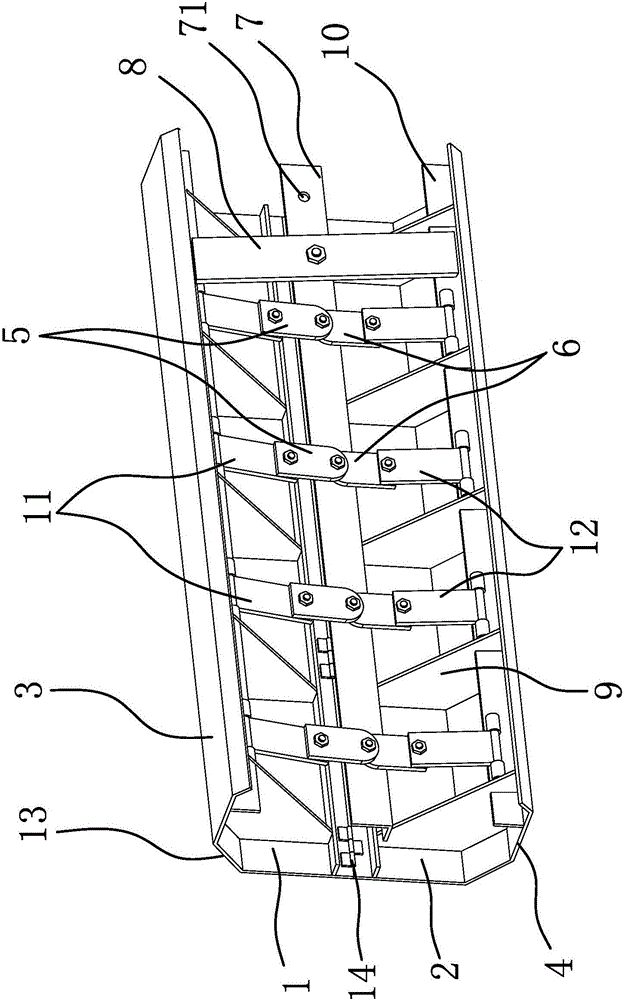

[0037] Such as figure 1 and figure 2 As shown, the detachable steel mandrel includes two support assemblies 100, and each support assembly 100 includes a strip-shaped petal body 1 and a strip-shaped petal body 2 2, and one side of the petal body 1 is connected to the petal body 1. One side of the body two 2 is hinged by a hinge 14, and the other side of the petal body one 1 and the other side of the petal body two 2 respectively have a plate body one 3 and a plate body two 4 bent in the same direction. Body one 3 and plate body two 4 are arranged oppositely, and plate body one 3 is hinged with a number of connecting arms one 5 facing plate body two 4 near the outer edge, and plate body two 4 is hinged near the outer edge with several connecting arms one 5 corresponding to each other. Connecting arm two 6, plate body one 3 and plate body two 4 are also provided with pull bar 7 along the length direction of petal body one 1 and petal body two 2, the ends of connecting arm one ...

Embodiment 2

[0042] This embodiment is a method for making a prestressed concrete hollow beam using the detachable steel mandrel in Embodiment 1. The method includes the following steps:

[0043] a. Install the steel frame: Build the steel frame on the flat ground, the steel frame is in the shape of a long strip, and the cross section of the steel frame is in the shape of a "mouth";

[0044] b. Install the peripheral board: fix the peripheral board on both sides of the steel frame, and the peripheral board is attached to the outer surface of the steel frame;

[0045] c. Install the corrugated pipe: fix the corrugated pipe in the steel frame, the bellows are arranged along the length direction of the steel frame, the bellows are distributed on both sides of the steel frame, and the two ends of the bellows protrude from the end of the steel frame;

[0046] d. Install the anchor seat: fix the anchor seat at both ends of the steel frame, position and fix the anchor seat with the positioning st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com