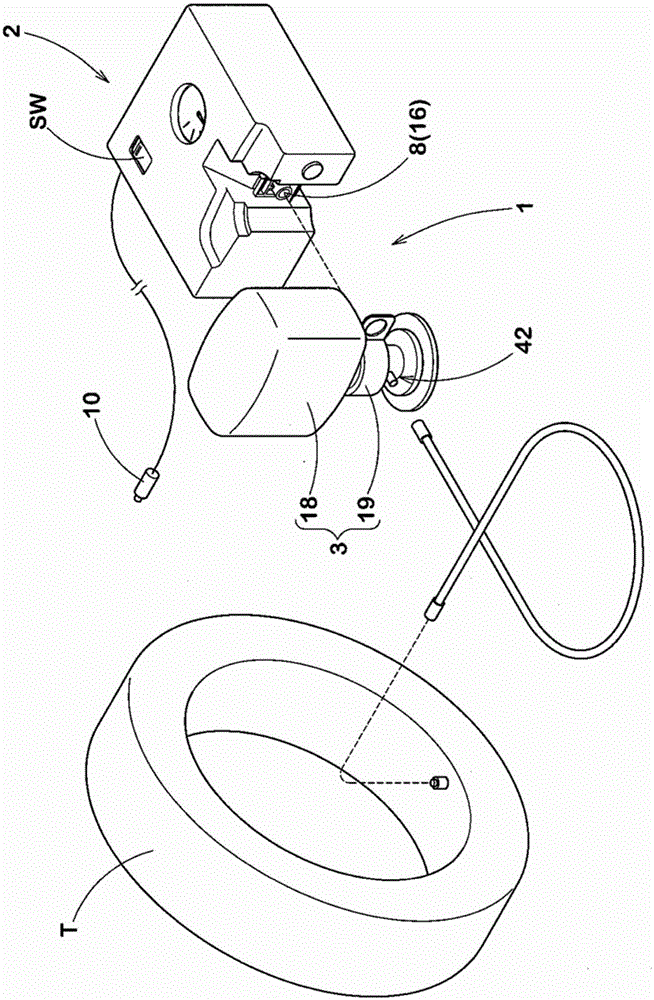

Tire puncture repair kit

A kit and tire technology, applied in the field of tire puncture repair kits, can solve the problems of miniaturization and cost reduction of compressor devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

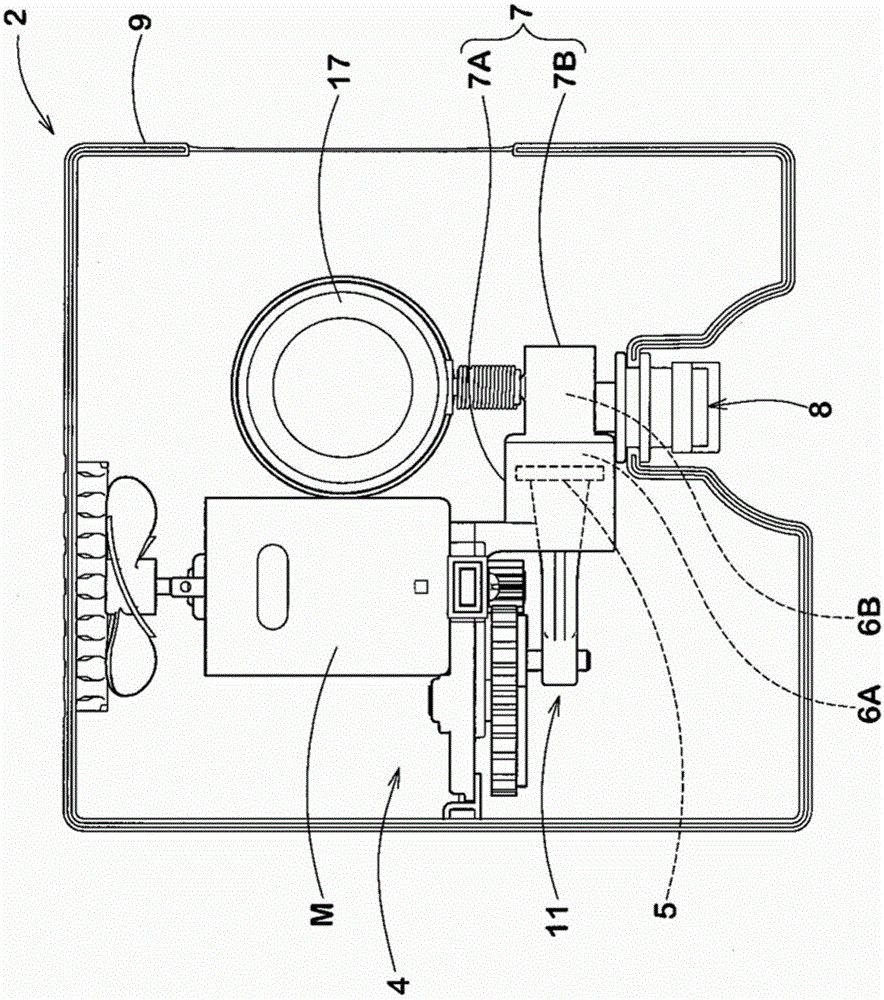

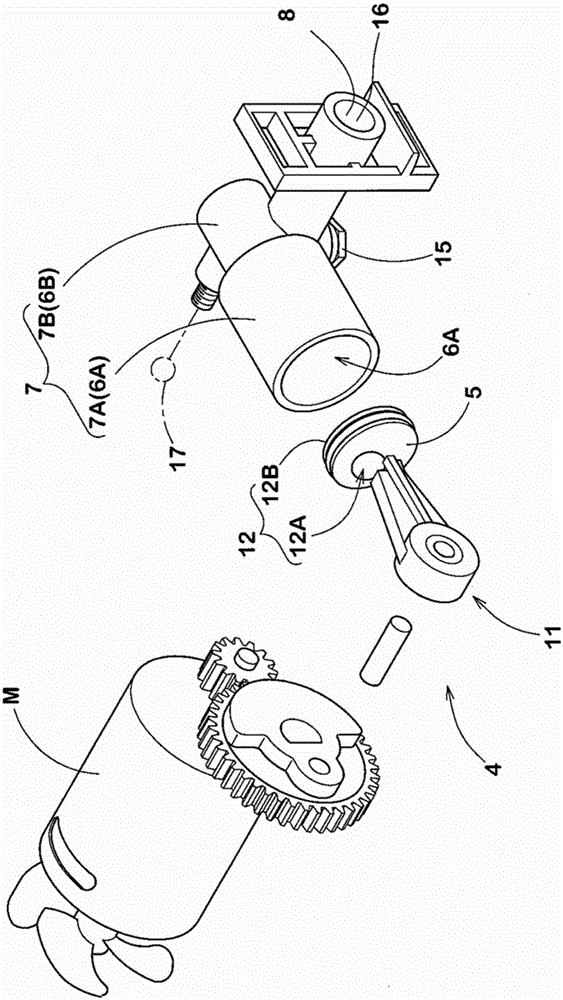

Embodiment

[0056] In order to confirm the effect of the present invention, a trial production was carried out according to the specifications in Table 1. Figure 1 ~ Figure 4 Compressor unit 2 shown. Then, each compressor device 2 is connected to the tire, and when the compressor device 2 is operated, a pressure sensor (different from the pressure gauge 17 ) is used to monitor pressure fluctuations in the shunt chamber 6B. Then, the pressure fluctuation was evaluated based on the difference between the maximum pressure Pmax (pressure when the piston reached the top dead center PU) and the minimum pressure Pmin (pressure when the piston reached the bottom dead center PL) of the split chamber 6B when 15 minutes had elapsed. In addition, the difference (deviation) between the tire internal pressure at the lapse of 15 minutes and the pressure indicated by the pressure gauge 17 was evaluated.

[0057] [Table 1]

[0058]

[0059] As shown in Table 1, it can be confirmed that the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com