A vacuum pressure swing adsorption system with stable voltage operation and its process

A vacuum pressure swing adsorption and process technology, applied in the field of pressure swing adsorption, can solve the problems of reduced fluctuation range, vacuum pump pressure fluctuation, pressure fluctuation, etc., and achieve the effect of reducing pressure fluctuation and reducing the pressure fluctuation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] This embodiment relates to a vacuum pressure swing adsorption system operating under constant pressure and a control process thereof.

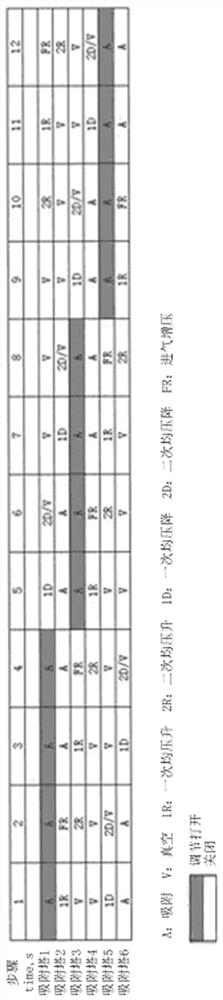

[0030] The vacuum pressure swing adsorption system consists of an adsorption tower, a fan and a vacuum pump. It adopts a six-tower process. The adsorption towers are divided into three groups, and each group consists of two adsorption towers.

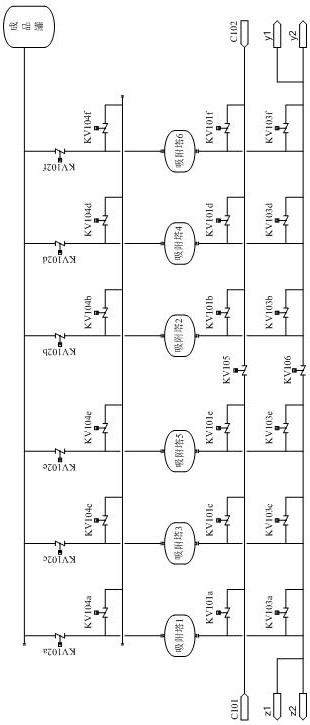

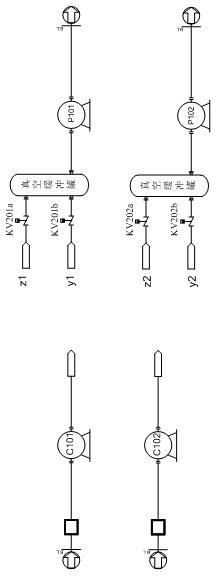

[0031] like figure 1 , figure 2 It can be known from the six-tower structure shown that there are six adsorption towers in total, from adsorption tower 1 to adsorption tower 6. The adsorption tower is provided with an air inlet at the bottom and an air outlet at the top. The air inlet is connected to a fan (C101, C102) or a vacuum pump. (P101, P102), the outlet end is connected to the finished product tank. In use, in order to facilitate the control of the adsorption tower, between the inlet end of each adsorption tower and the fan, the inlet end of each adsorption tower and the vacuum pump, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com