An environmentally friendly decorative film and its production method

A production method and decorative film technology, which are applied in special decorative structures, decorative arts, chemical instruments and methods, etc., to achieve the effects of low energy consumption, favorable production cost control, and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An environmentally friendly decorative film, which is made of plastic decorative film and PET backing protective film through thermal lamination. PVC film; if the plastic decorative film is PVC film, the bonding temperature is 100-130°C; if the selected plastic decorative film is EVA film, the bonding temperature is 60-80°C, which is more energy-saving and environmentally friendly; the plastic decorative film The surface has a decorative pattern. The hardness value of the plastic decorative film is 50~70 Pa. The decorative pattern is embossed, printed or a combination of embossed and printed. The plastic decorative film is not electrostatically treated, and does not need any adhesive for bonding.

[0024] The decorative film of the present invention has a two-layer structure, the surface layer is a plastic decorative film layer, and the bottom layer is a PET protective layer. The film of the present invention does not do electrostatic treatment, does not apply glue, ...

Embodiment 2

[0027] A method for making an environmentally friendly decorative film. The film is made of a plastic decorative film and a PET backing protective film through thermal bonding. The bonding temperature is 60-130°C. If the plastic decorative film is a PVC film, the bonding Temperature The temperature is 100~130°C; if the selected plastic decorative film is EVA film, the bonding temperature is 60~80°C, which is more energy-saving and environmentally friendly. The surface of the plastic decorative film has decorative patterns. The hardness value of the plastic decorative film is 50~70 Pa. The decorative pattern can be embossed, printed or a combination of embossed and printed.

[0028] The decorative pattern described in this embodiment is a colored pattern that is printed and then pressed.

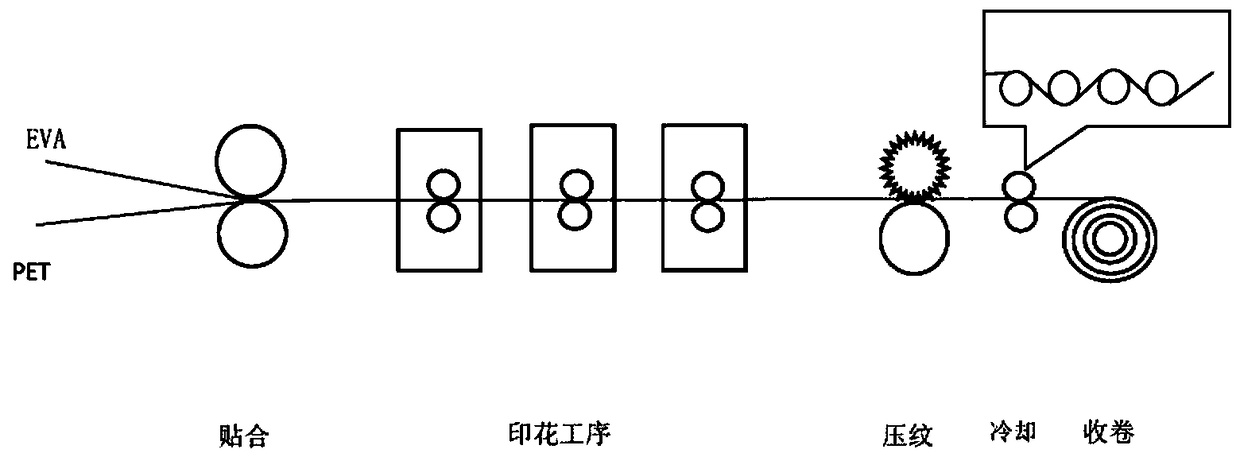

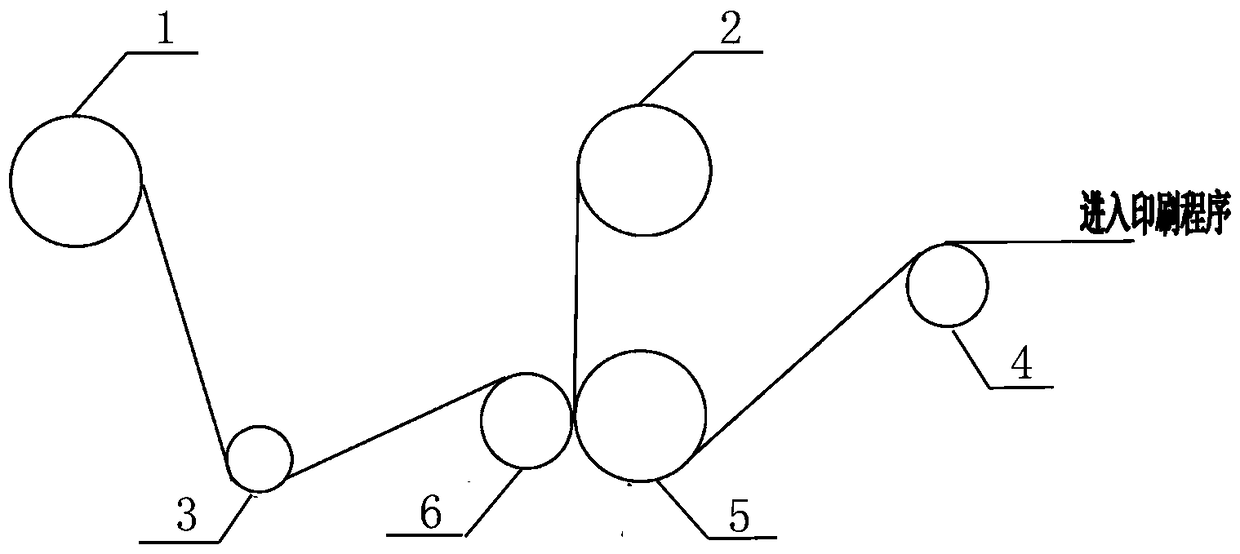

[0029] The manufacturing method comprises the following steps: laminating, making decorative pattern and cooling and shaping (see figure 1 ); the bonding method is that the plastic decorat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com