Novel front axle

A technology of I-beam and hypotenuse, which is applied in axles, vehicle parts, transportation and packaging, etc., can solve the problems of affecting vehicle stability and insufficient torsion resistance, and achieve enhanced vehicle stability, strong torsion resistance, and reduced The effect of the accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

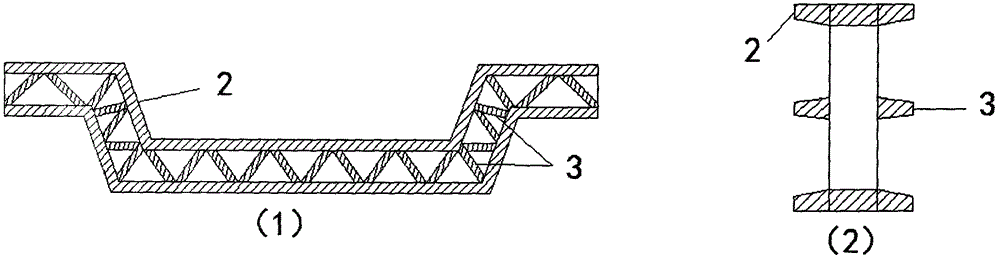

[0009] attached figure 2 It is a schematic structural view of a specific embodiment of the present invention, 2 in the figure is an I-shaped steel shaft body, and 3 is a hypotenuse.

[0010] The main structure of the present invention is as figure 2 As shown, it is mainly composed of an I-shaped steel shaft body 2 and a hypotenuse 3. The hypotenuse and the upper and lower convex sides of the I-shaped steel shaft body form a triangular structure, and the width of the hypotenuse is at least equal to the width of the upper and lower convex sides of the I-shaped steel.

[0011] When working, the beveled edge strengthens the strength of the I-beam front axle, has strong bending and torsion resistance, is not easy to bend and deform, enhances vehicle stability, reduces accidents, and ensures the safety of life and property. The I-beam triangle is used to strengthen the new front axle It can replace the existing I-beam front axle and be used as the front axle of the vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com