Limit bushing for limiting ultimate displacement of engine

A limit displacement and engine technology, applied in the field of limit bushing, can solve problems such as difficult to meet the limit design requirements, large limit deformation of the engine, abnormal noise of the whole vehicle, etc., achieve significant practical value, good structural stability, avoid The effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

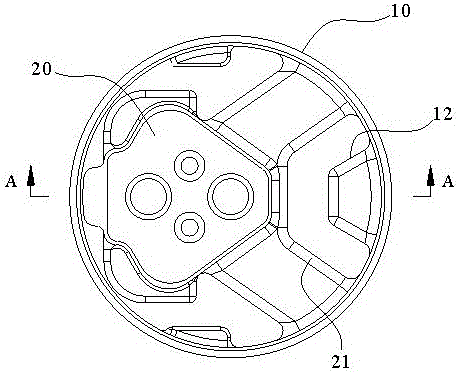

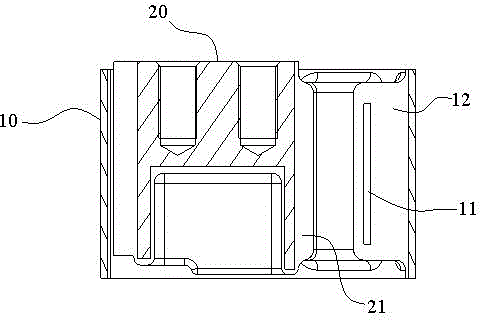

[0013] Such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention provides a limit sleeve for limiting the limit displacement of the engine, including a sleeve 10, and a “﹝”-shaped limit bracket 11 is fixed inside the sleeve 10, and the sleeve 10 is provided with There is a suspension cushion 20, the suspension cushion 20 is provided with a limit stopper 21, and the limit stopper 21 cooperates with the limit bracket 11, wherein the limit bracket 11 can be made of the same material as the casing 10 Manufactured and welded with the sleeve 10, the geometric relationship between the length L of the limit bracket 11 and the length H of the sleeve 10 is: 1 / 2H≤L≤4 / 5H, this geometric constraint can reduce the raw material The structural strength of the limit bracket 11 is maximized while reducing the cost. In this technical solution, by adding a limit bracket 11 in the bushing 10, the hardness of the vulcanized rubber block used in the prior art is high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com