Vehicle wheel hub packaging cover

A hub and wheel technology, applied in the field of storage and transportation of aluminum alloy hubs, can solve problems such as hub bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

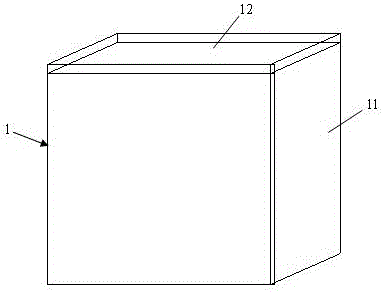

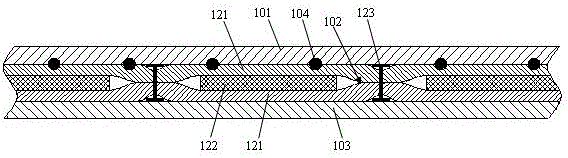

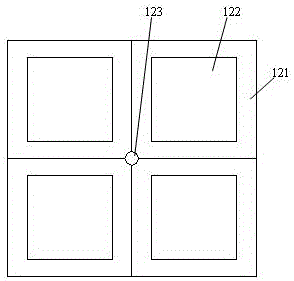

[0014] As shown in the figure, this embodiment provides a wheel hub packaging cover, including a cover body 1, the cover body 1 includes four side walls 11 and a top wall 12; the cover body 1 includes outer plastic layers that are overlapped 101, the inner non-woven fabric layer 103 and the middle anti-collision cotton layer 102; the anti-collision cotton layer 102 includes two gauze layers 121 and several square foamed plastics 122 sandwiched between the two gauze layers 121, Fixing blocks 123 for fixing the two gauze layers 121 are arranged outside the four corners of each square foamed plastic 122 .

[0015] Between the outer plastic layer 101 and the anti-collision cotton layer 102 are fixed a plurality of parallel cylindrical metal strips 104 .

[0016] The cylindrical metal strip 104 is made of aluminum alloy.

[0017] The fixing block 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com