Logistics trolley track commutation retracking device

A trolley track and logistics technology, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of difficult device installation and maintenance, difficult lubrication of bearings, wear, and unstable operation, etc., to achieve low noise, low transmission noise, The effect of simplifying the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

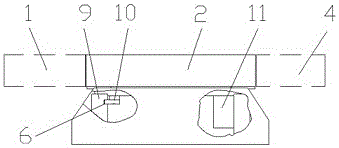

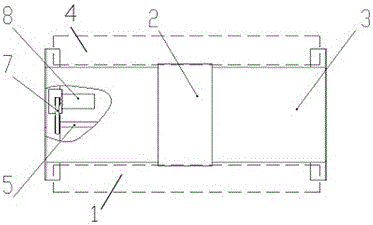

[0014] like Figure 1-2 As shown, a track reversing switcher for logistics trolleys of the present invention includes a reversing track 2 and a switcher frame 3, on which a screw mandrel 5 and a motor 8 and two pulleys of a belt drive 7 are installed Cooperate with the screw rod 5 and the motor 8 to install respectively, the beam 9 is fixed under the frame 3 of the rail switch, the composite bearing 10 cooperates with the guide chute 6 on the beam 9, the composite bearing 10 has a self-lubricating effect, and the ordinary linear bearing 11 and the beam 9 The optical axis on the other side mates.

[0015] When working, the motor 8 rotates, and the belt drive 7 drives the screw mandrel 5 to rotate, and the screw mandrel 5 drives the reversing track 2 to move along the beam 9 through the composite bearing 10 and the ordinary linear bearing fixedly installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com