Double roll cloth system with adjustable cloth stroke

A stroke and spreading technology, applied in the direction of winding strips, spreading thin soft materials, thin material processing, etc., can solve the problems of inability to straighten the edge of the cloth, unadjustable spreading stroke, and low spreading efficiency. , to achieve the effect of reliable pressing operation, high cloth pulling work efficiency and simple mechanism structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

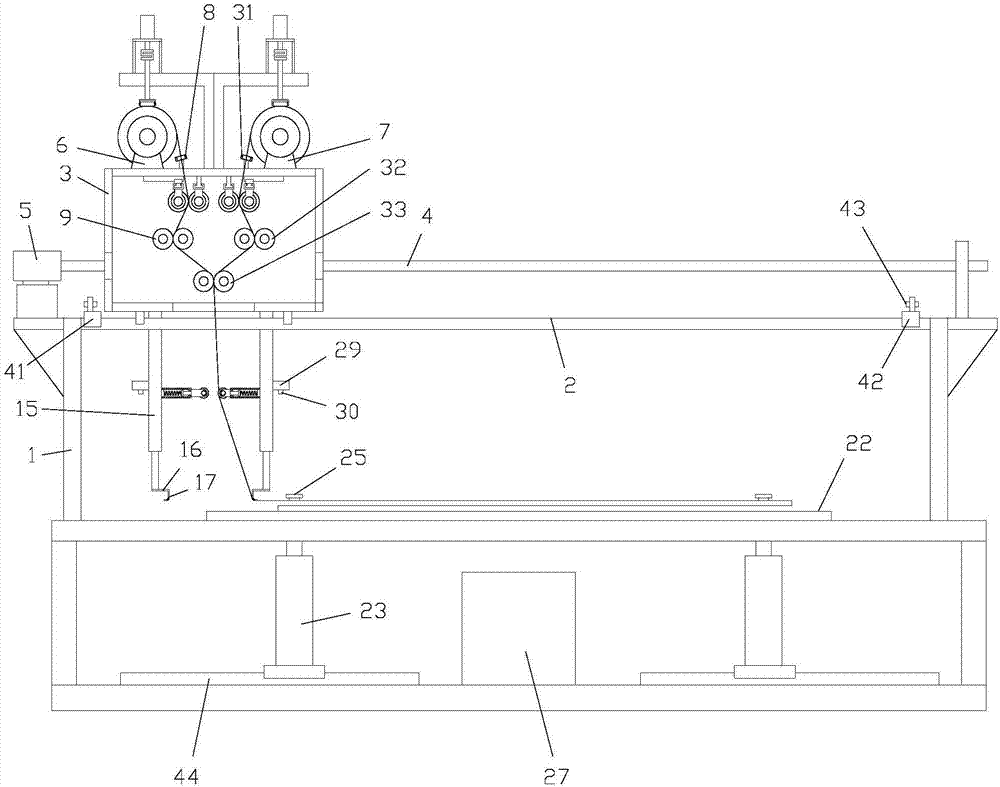

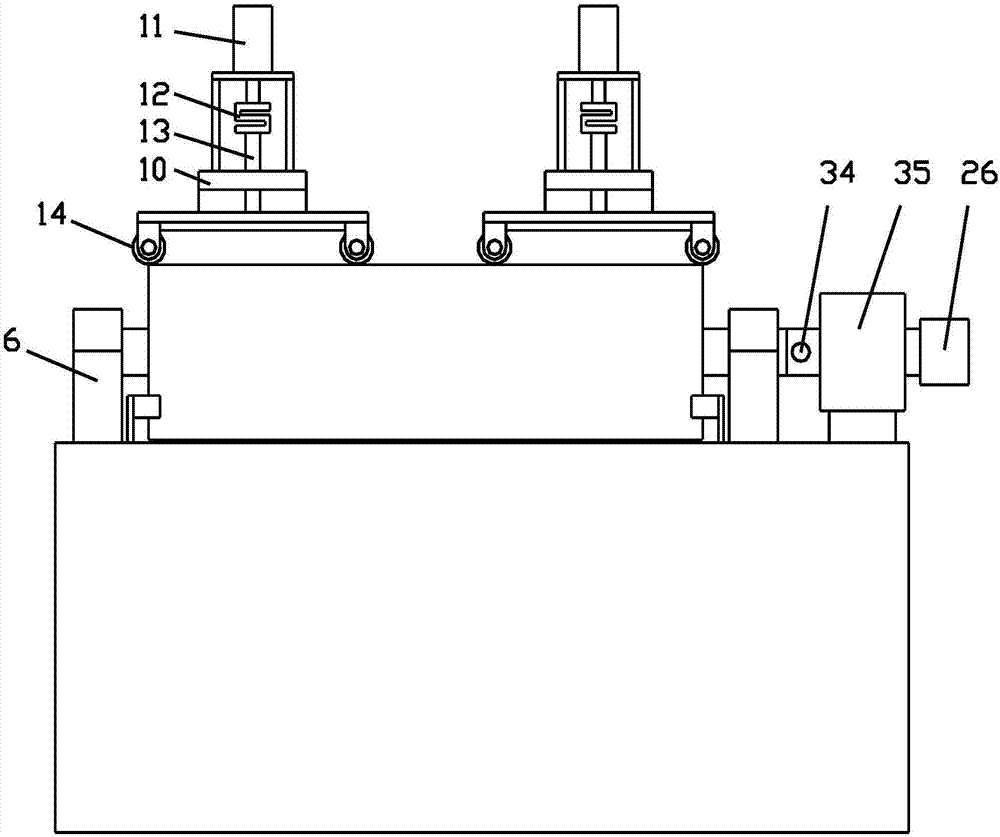

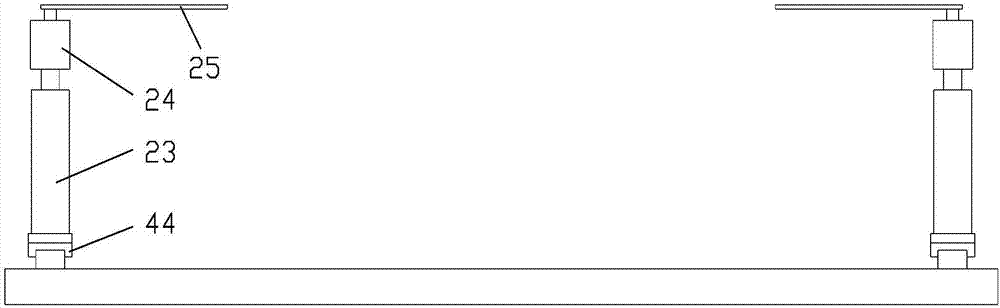

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0035] As shown in the figure, the double-coil pulling cloth system with adjustable pulling stroke in this embodiment includes a frame 1 on which a horizontal straight guide rail 2 is provided, and the horizontal straight guide rail is provided with a moving part slidingly matched with it. Frame 3, the frame is also provided with a screw rod 4 and a motor 5 that drives the screw rod to rotate, and the screw rod is threadedly matched with the moving frame; the motor is a stepper motor;

[0036] The horizontal straight guide rail is also provided with a left positioning block 41 and a right positioning block 42 whose installation position can be slidably adjusted, the moving frame is located between the left positioning block and the right positioning block, and the left positioning block and the right positioning block Proximity sensors 43 for detecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com