An adsorption tank used in hydrogen peroxide purification process

A technology of purification process and adsorption tank, applied in the direction of peroxide/peroxy hydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, chemical instruments and methods, etc., can solve the final product refining and product purity impact, content increase, etc., to ease the heat accumulation process, prevent equipment damage, and help heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

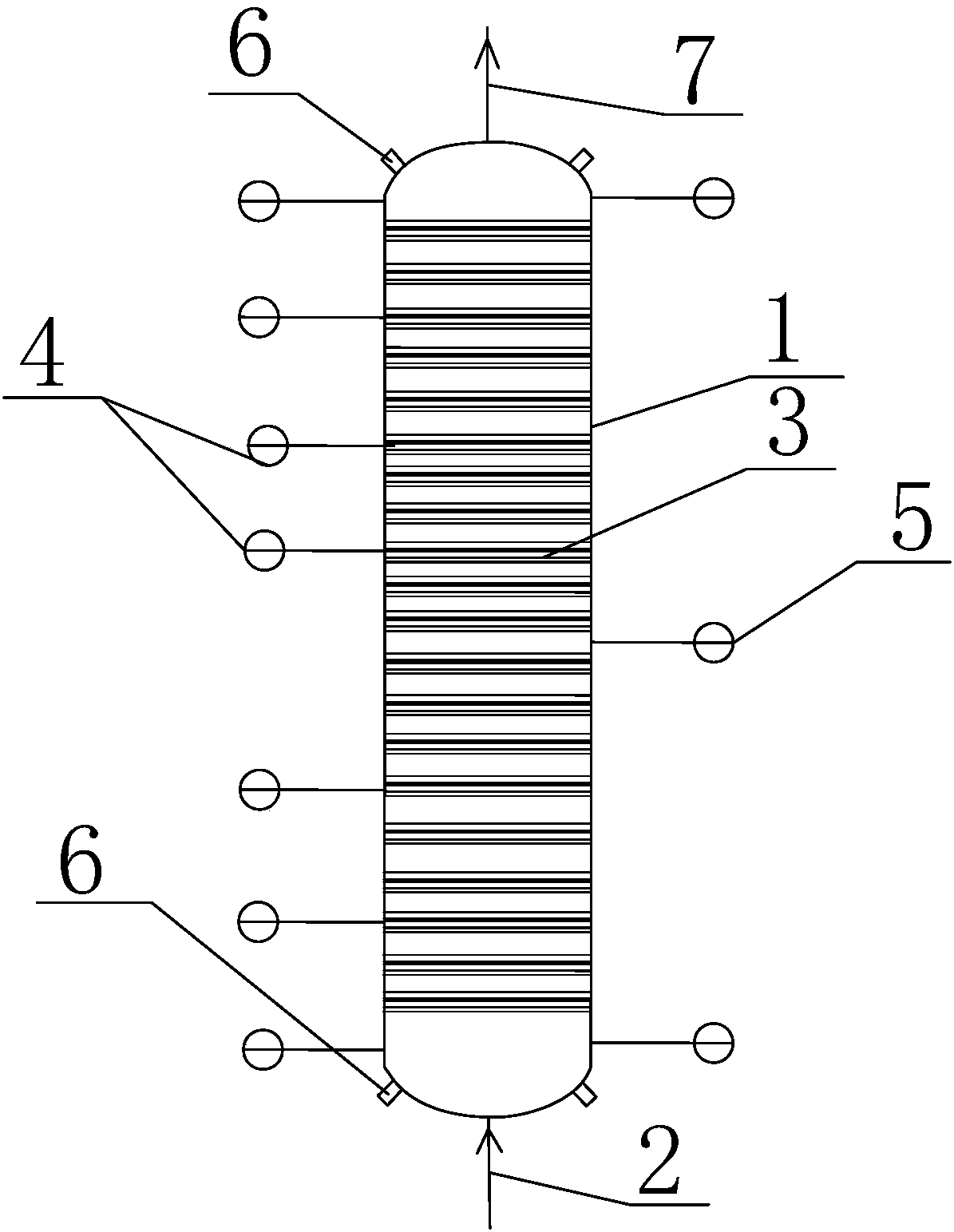

[0011] The present invention provides an adsorption tank used in the purification process of hydrogen peroxide. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0012] The invention provides an adsorption tank used in hydrogen peroxide purification process, such as figure 1 As shown, it includes a vertically arranged tank body 1, wherein the bottom of the tank body 1 is provided with a feed port 2, and the top of the tank body is provided with a discharge port 7, and there are many tanks arranged from top to bottom in the tank body 1. Each resin bed 3, the thickness of each resin bed 3 is less than or equal to 30cm, and the interval between adjacent resin beds is greater than or equal to 5cm.

[0013] Fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com