A continuous supercritical water gasifier for Zhundong coal

A technology of supercritical water gasification and supercritical water, which is applied in the manufacture of combustible gas, bulk chemical production, petroleum industry, etc., can solve the problems of reducing coal gasification efficiency, coking and clogging of feed materials, affecting the continuous and stable operation of the reactor, etc. , to avoid the contamination problem, improve the gasification rate, and achieve the effect of new large-scale utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

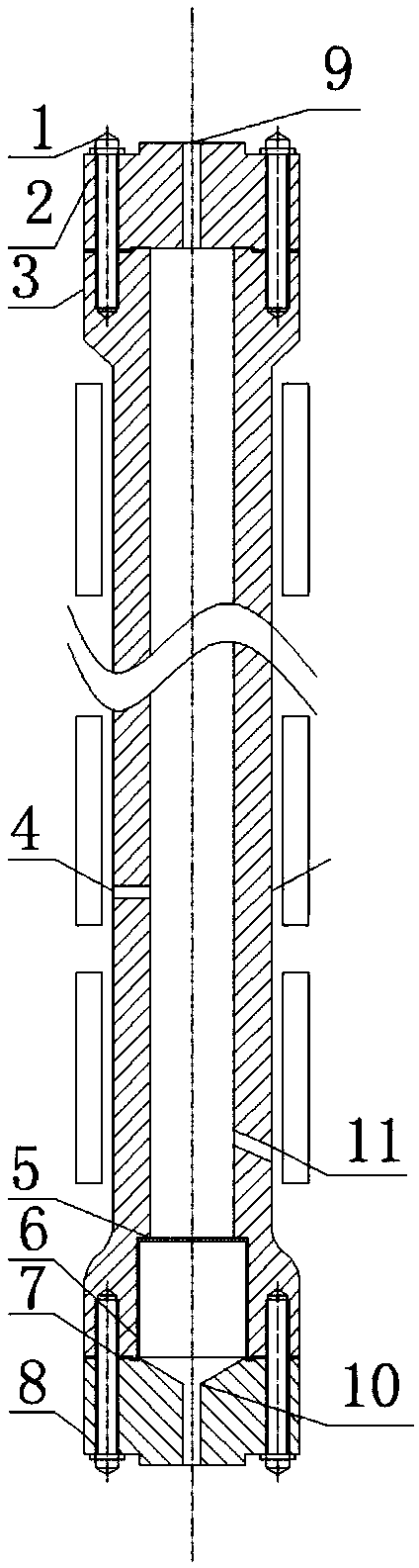

[0028] A continuous supercritical water gasifier for Zhundong coal, comprising an upper end cover 2, a fluidized bed body 3, a coal slurry inlet 4, a distribution plate 5, fasteners 6, a lower end cover 8, and a reaction product liquid outlet 9, , supercritical water inlet 10 and slag outlet 11; upper end cover 2 and lower end cover 8 are fixed on the upper end and lower end of fluidized bed main body 3 by fastening screw 1; fluidized bed main body 3 is provided with reaction chamber; upper end cover 2 The center is provided with a reaction liquid outlet 9 connected to the reaction chamber. The middle part of the fluidized bed body 3 is horizontally provided with a coal slurry inlet 4 connected to the reaction chamber. Below the coal slurry inlet 4; the lower end of the reaction chamber of the fluidized bed body 3 is provided with a fastener 6, and the upper end of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap