Water saving device of full-automatic washing machine and washing machine with water saving device

A fully automatic washing machine and water-saving device technology, applied in the field of washing machines, can solve the problems of secondary pollution of clothes, many sealing links, breeding of bacteria and mildew, etc., to prevent secondary pollution, less sealing links, and easy to implement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

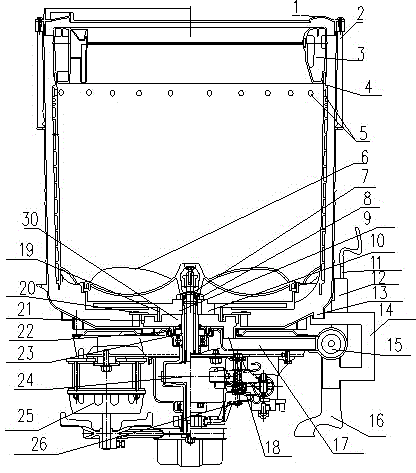

[0019] combine figure 1 , is a structural schematic diagram of an embodiment of a water-saving device for a fully automatic washing machine according to the present invention, including an inner tub 4 and an outer tub 2, the inner tub 4 is concentrically installed in the outer tub 2, and a deceleration clutch 24 is installed on the outer tub 2, and is characterized in that: The inner barrel 4 described above is an integral water storage barrel, the outer barrel 2 is a drain barrel, and a water storage cavity 30 is formed between the inner barrel 4, the outer barrel 2 and the deceleration clutch 24, and the inner barrel 4 passes through the water storage cavity 3 and is installed under the outer barrel 2. Drain valve 15 is connected to storage and drainage.

[0020] More specifically, a balance ring is provided at the uppermost end of the inner tub 4 , and a circle of dehydration holes 5 facing the central axis of the inner tub 4 is provided next to the lower end of the balance...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap