Automobile metal bracket strengthening nut plate structure

A technology for metal brackets and reinforced nuts, which is applied to nuts, connecting components, threaded fasteners, etc., can solve the problems of reducing the bearing capacity of nuts in service life, reducing the safety of nut plates, and breaking the bearing capacity, so as to increase weight and improve Automobile safety performance and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, it is easy to clearly understand the technical means, creative features, achievement of purpose and effect of the present invention. Below in conjunction with specific illustrations, further elaborate the present invention:

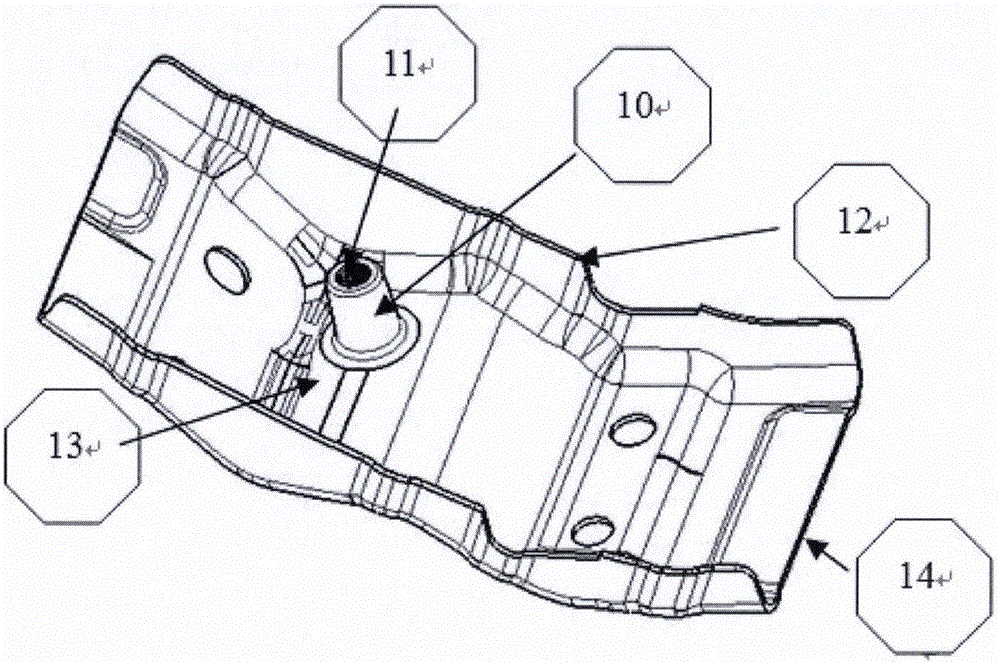

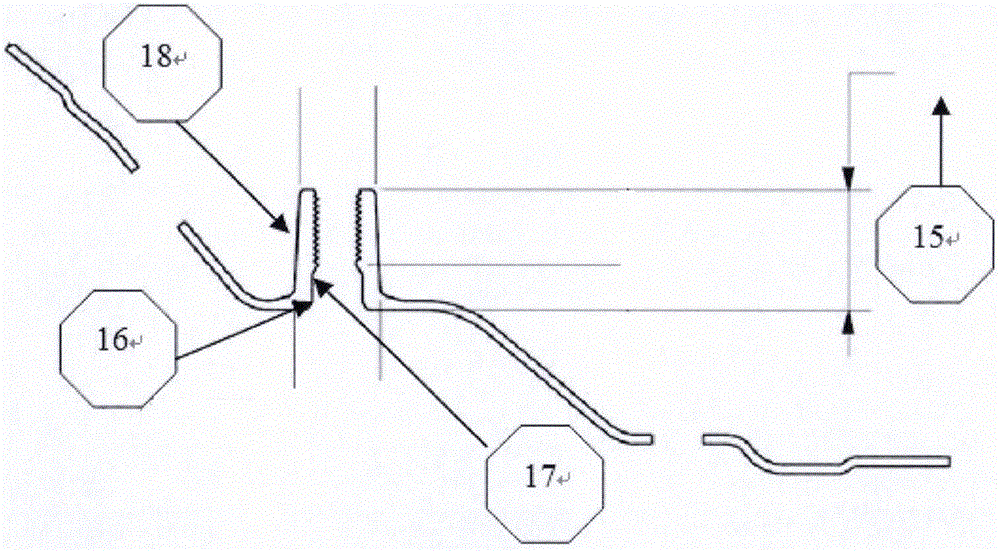

[0018] see figure 1 and figure 2 , an automobile metal bracket reinforced nut plate structure, wherein the material perception, chemical composition, and mechanical performance requirements of the automobile metal bracket are: analyzed by a spectrum analyzer; a, C: ≤0.10; b, Mn: ≤0.50; c, P: ≤0.025; d, S: ≤0.02; e, AL: ≥0.015; achieved by using a universal testing machine; a, yield strength 180-290Mpa; b, tensile strength 270-400Mpa; c, elongation ≥ 34 %;

[0019] see figure 1 and figure 2 , as shown in the schematic diagram of the appearance of the nut plate of the present invention, an integral nut plate 14 of an automobile metal bracket, the nut plate is an integral structure of parts and com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com