Centrifugal oil throwing atomization structure

An oil-throwing atomizer and oil-throwing technology, applied in the combustion method, combustion chamber, combustion equipment and other directions, can solve the problems of difficult ignition, poor atomization effect, low combustion efficiency, etc., and achieve good fuel atomization effect and ignition. Easy, efficient combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

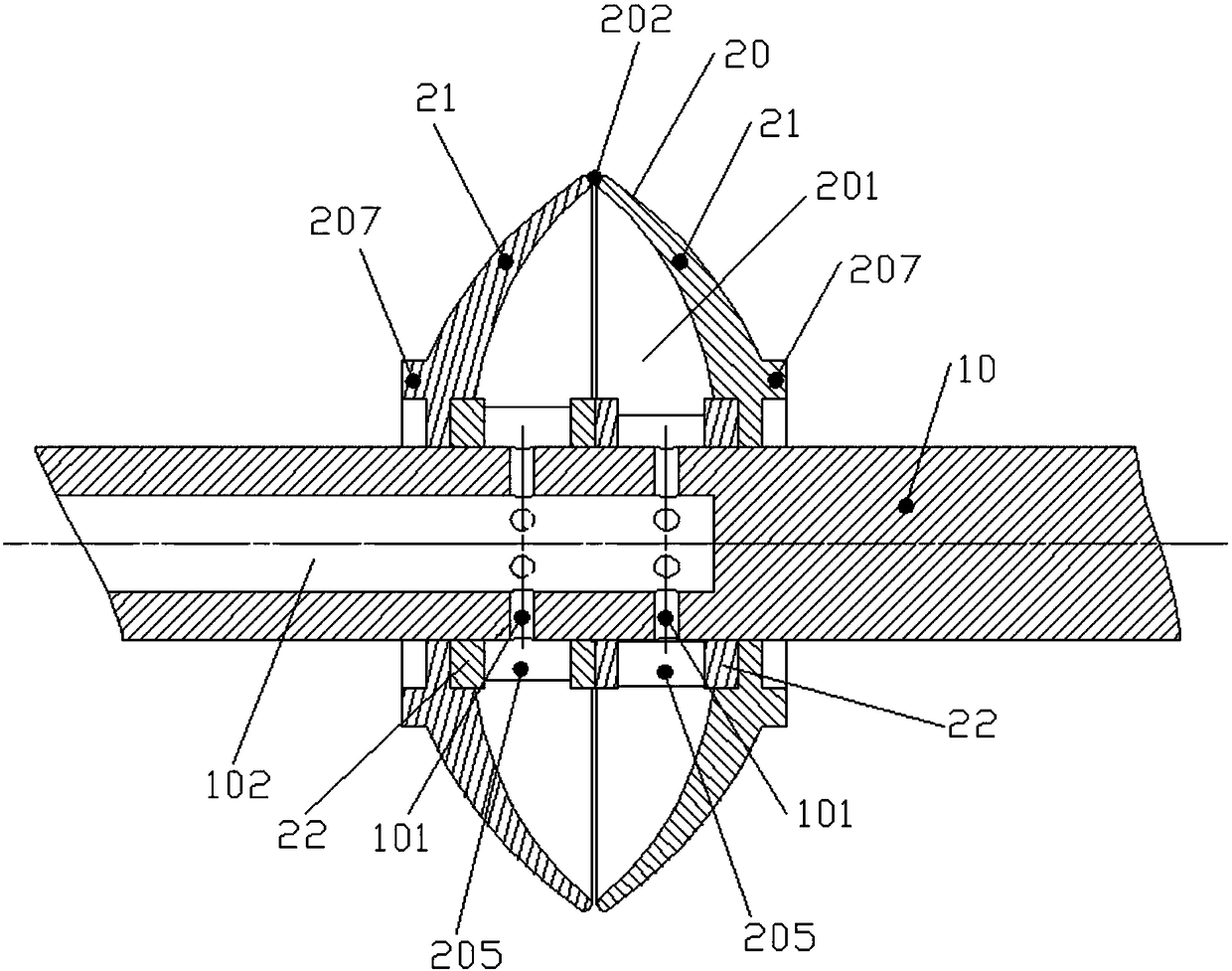

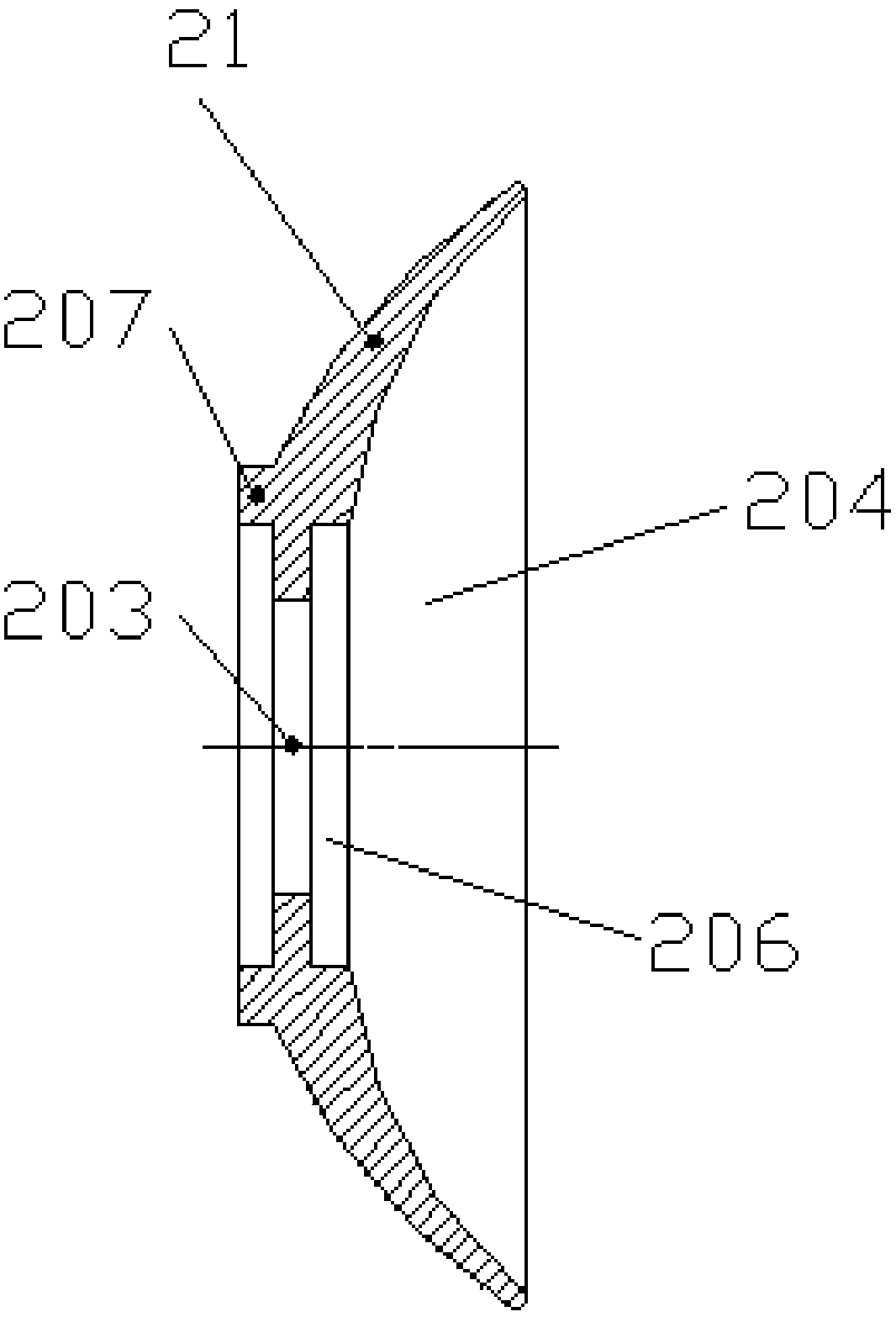

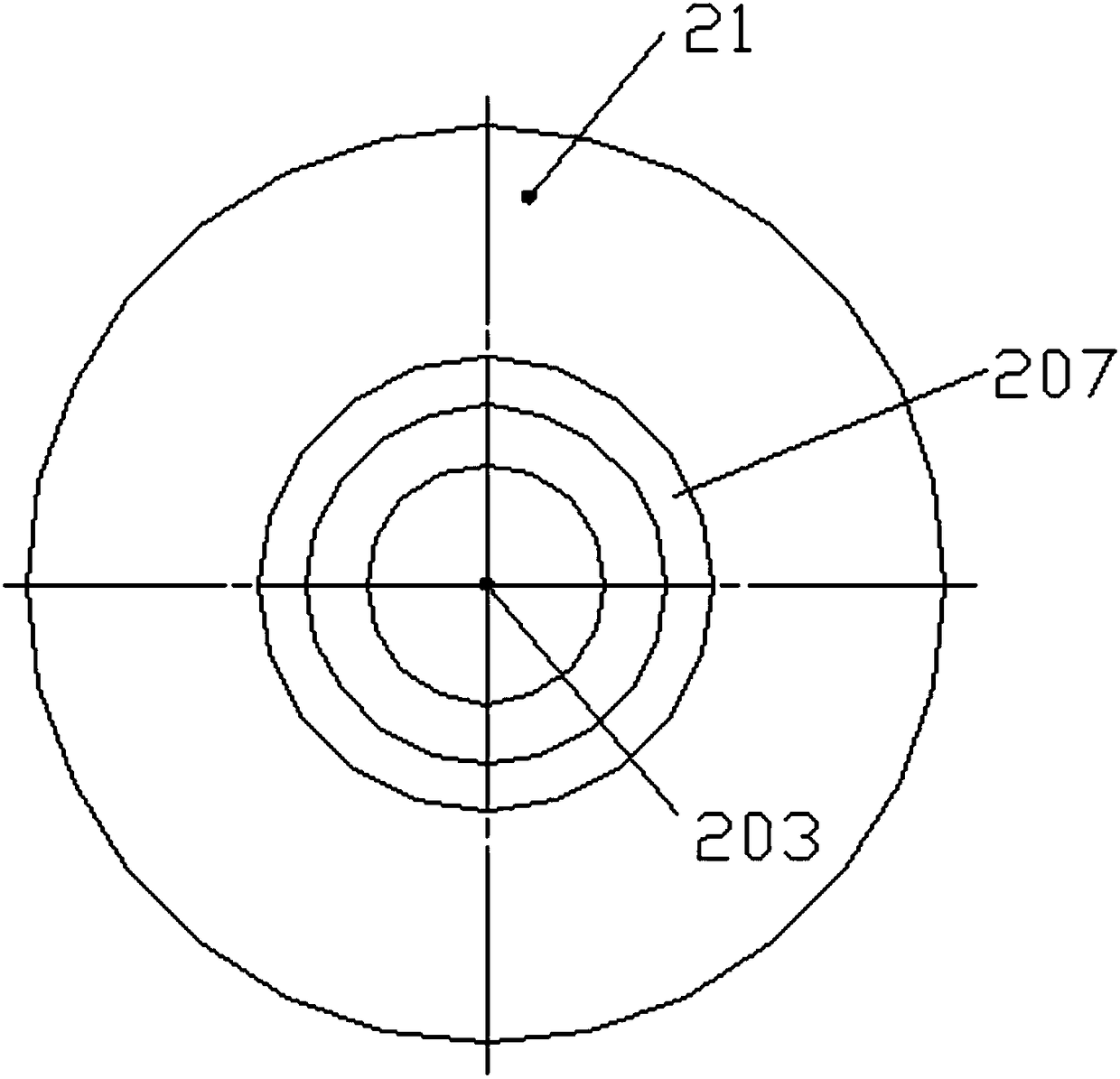

[0027] refer to figure 1 , the preferred embodiment of the present invention provides a centrifugal oil atomization structure, which is used to arrange in the flame tube (not shown) of the engine to provide atomized fuel to the combustion chamber (not shown) of the engine. The oil atomization structure includes: a rotating main shaft 10 communicated with the fuel tank of the engine (not shown in the figure), and the rotating main shaft 10 is equipped with an oil throwing device for throwing the incoming fuel out in the state of an oil film under the action of centrifugal force to atomize the fuel. Atomizer 20. The oil throwing atomizer 20 has an oil throwing chamber 201 , and the rotating spindle 10 is provided with a plurality of oil outlet holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com