Double-layer load mesh belt type baking machine

A roasting machine and mesh belt technology, which is applied in the direction of dryers, drying, drying solid materials, etc., can solve the problems of not being able to fully utilize and recycle heat resources, occupy a large space, and have low thermal efficiency, so as to improve the heat source The utilization rate and production efficiency, easy maintenance and replacement, and the effect of saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Book invention Not limited to the examples, the following Attached picture describe invention work process.

[0027] In order to make this invention The purpose, technical solutions and advantages of the technology are more clearly understood, the following combination Attached picture and embodiment, for this invention In further detail, the double-layer load conveying device of the double-layer load mesh belt roaster described here adopts a multi-layer cycle operation structure, and the specific examples are only used to explain the present invention. invention , is not used to limit the invention .

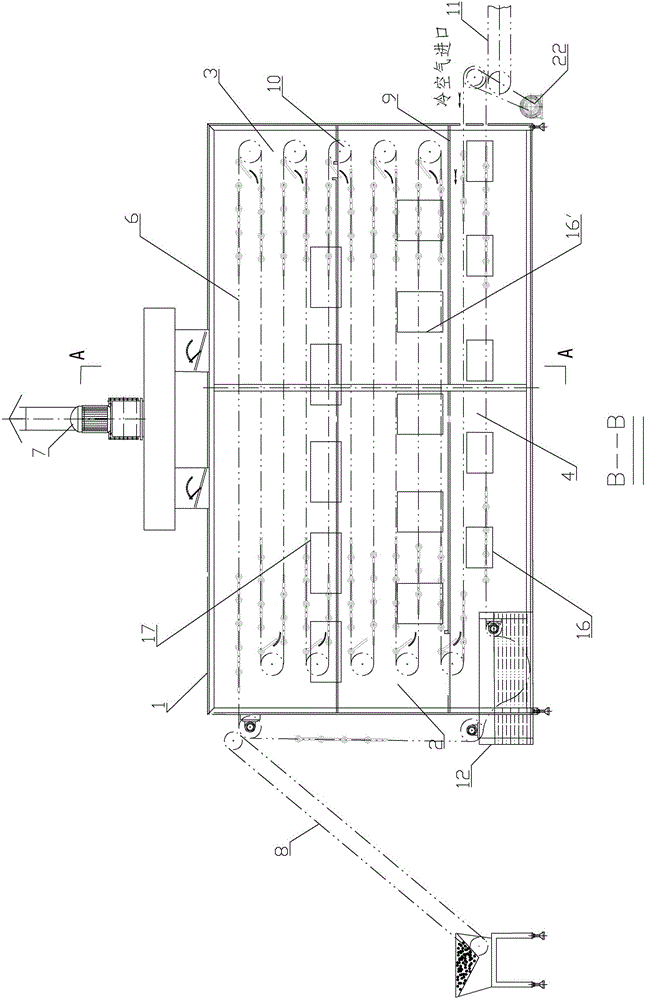

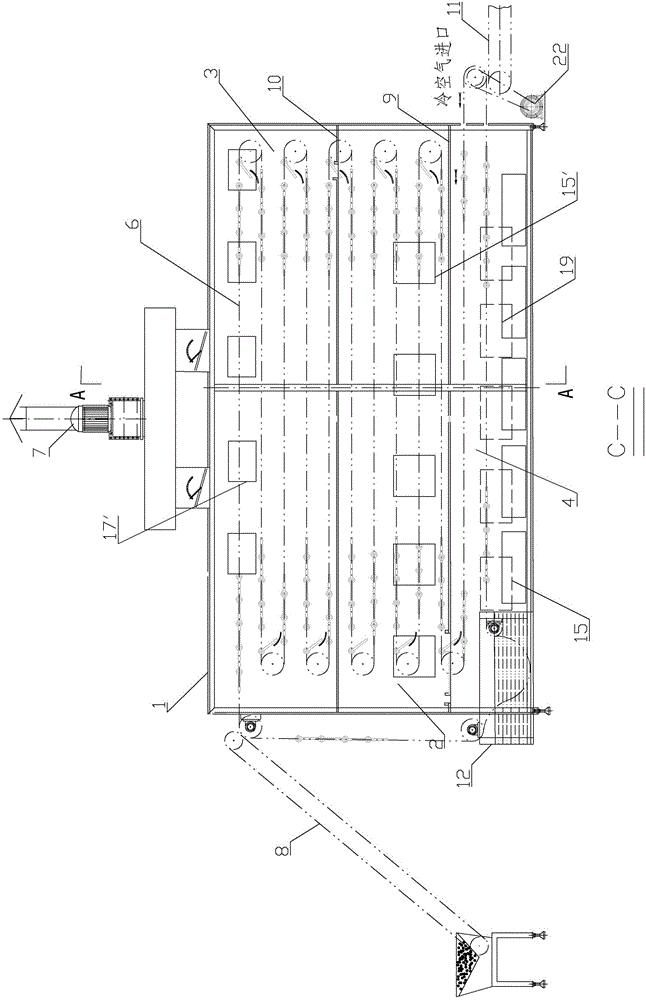

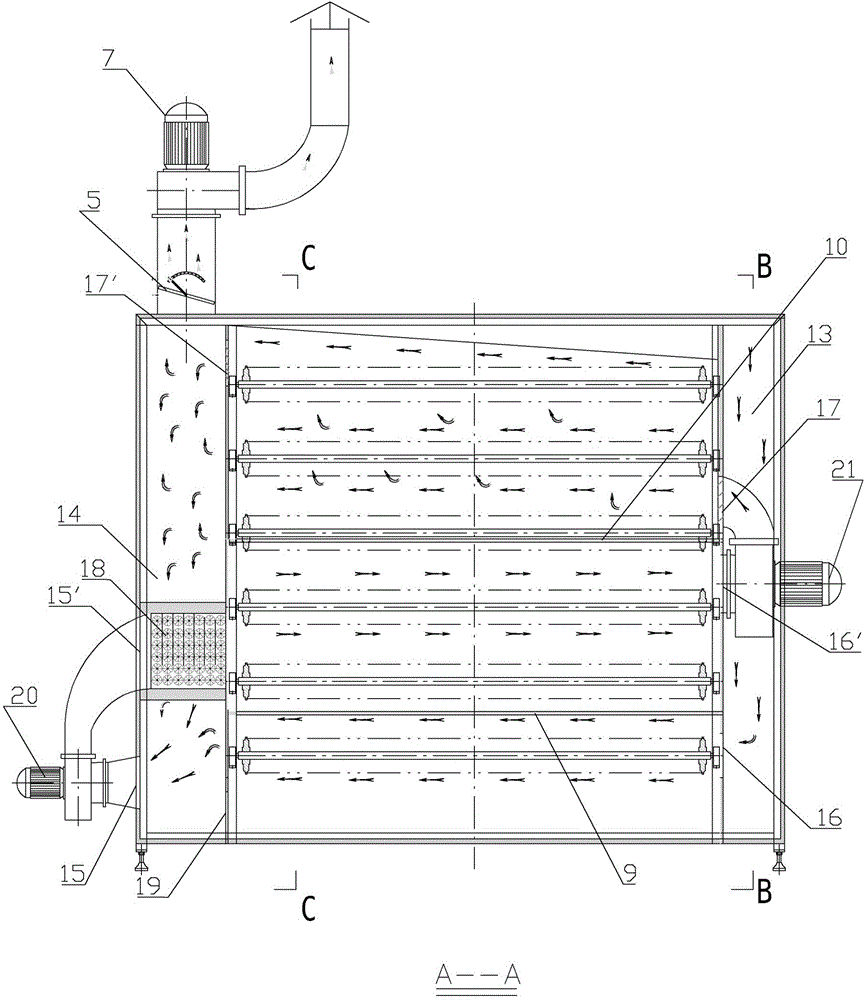

[0028] as shown in the picture 1, 2, 3, and 4: the double-layer load mesh belt type box (1) is equipped with six layers of horizontal double-layer load conveyor belts (6), which are especially suitable for sheets, strips, and granules with good air permeability For the baking of pasty materials such as filter cakes, they can be baked after being shaped by a g...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap