A color filter substrate and its manufacturing method and display panel

A technology for a color filter substrate and a manufacturing method is applied in the field of a color filter substrate, a manufacturing method thereof, and a display panel, which can solve problems such as large angle difference, and achieve the effects of reducing the angle difference, reducing the risk of light leakage, and ensuring the OD value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

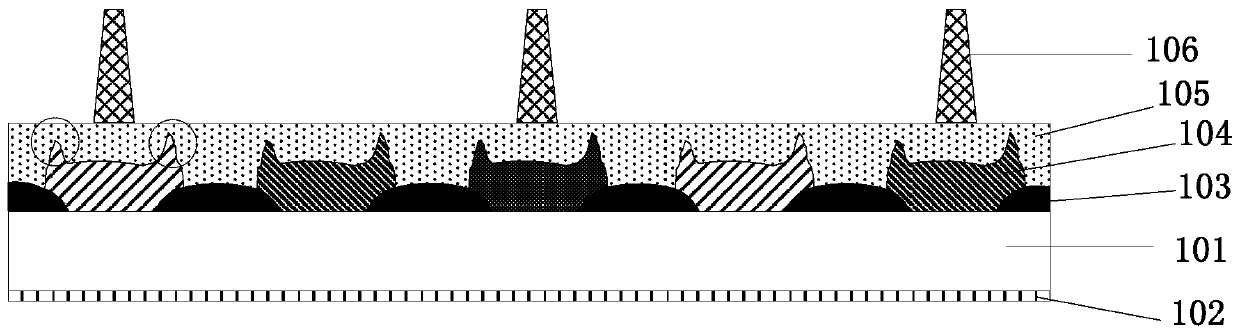

Image

Examples

Embodiment Construction

[0044] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the following will clearly and completely describe the technical solutions of the embodiments of the present invention in conjunction with the drawings of the embodiments of the present invention.

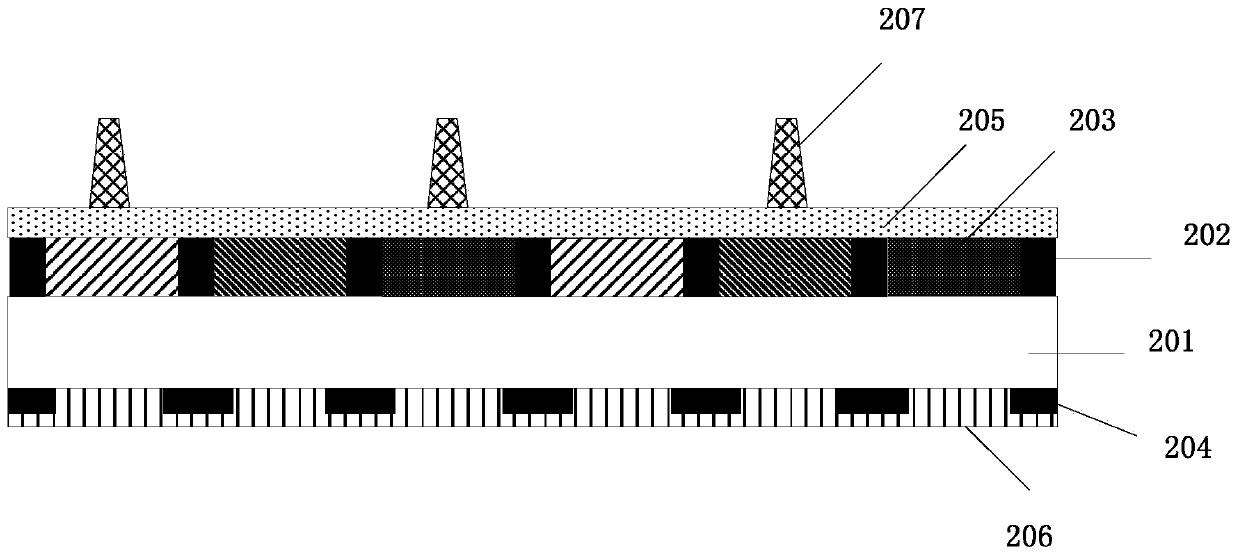

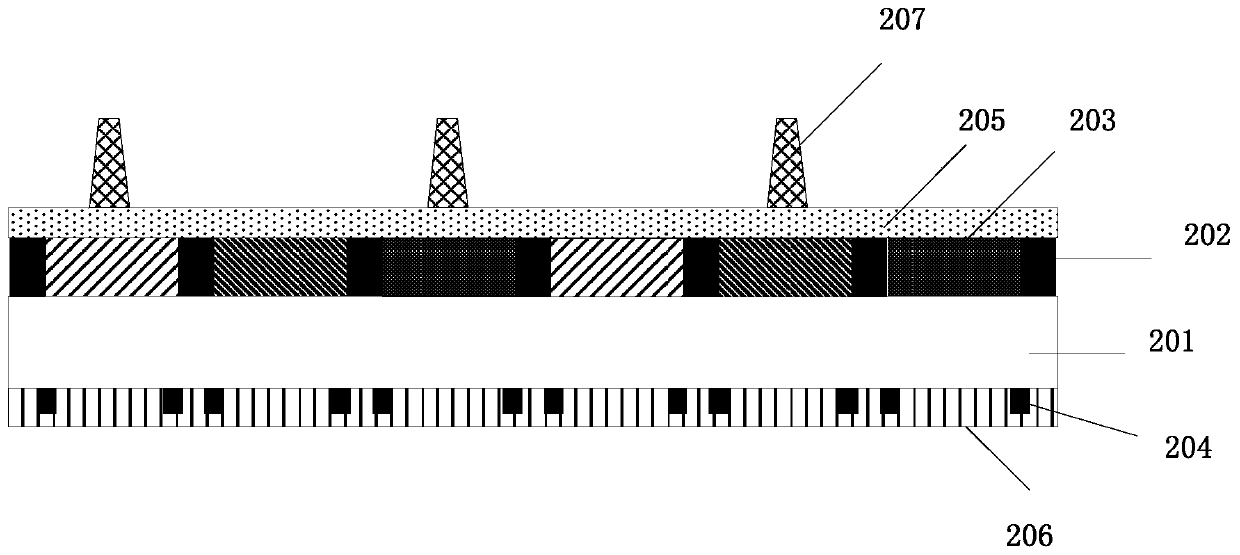

[0045] Please refer to figure 2 , figure 2 It is a schematic structural diagram of a color filter substrate according to Embodiment 1 of the present invention, and the color filter substrate includes:

[0046] Substrate substrate 201;

[0047] The first black matrix 202 and the color filter unit 203 arranged on one side of the base substrate 201, the first black matrix defines a plurality of pixel regions, and the color filter unit 203 is only arranged in the pixel region That is, the first black matrix 202 and the color filter unit 203 are arranged in the same layer and do not overlap.

[0048] The second black matrix 204 disposed on the other side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com