Support device for flexible coupling of diesel engine

A technology of elastic couplings and supporting devices, which is applied in the direction of rigid shaft couplings, couplings, mechanical equipment, etc., can solve problems affecting the stable operation of the unit, reduce the gear difference, ensure stable operation, and improve accuracy. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

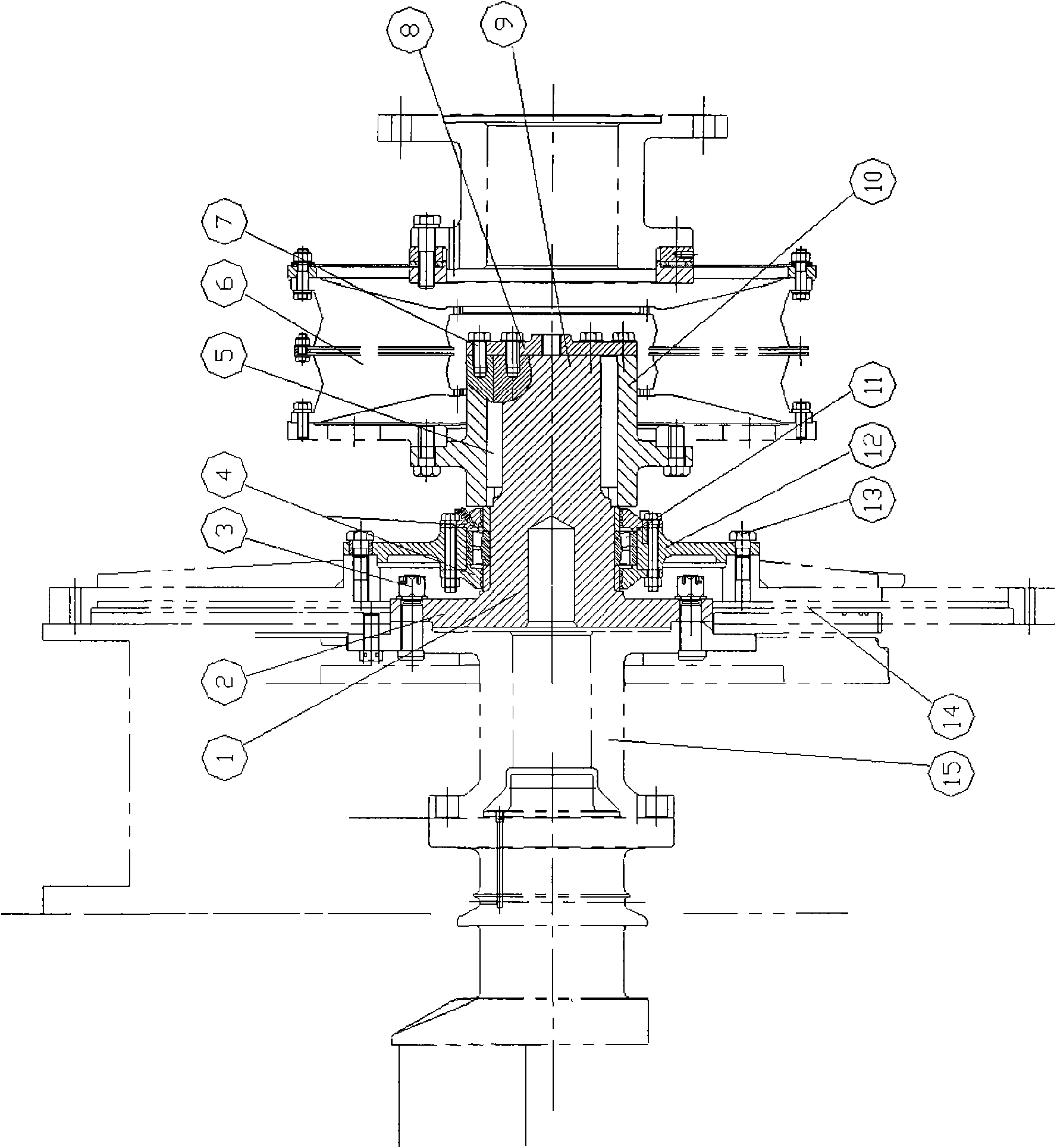

[0007] See attached figure 1 , the diesel engine elastic coupling support device of this embodiment, the flange end (2) of the connecting shaft (1) is docked with the output end (15) of the crankshaft of the diesel engine through the bolt (3), and there is provided near the flange end (2) Spherical rolling bearing (11), two bearing glands (4) bearing is fixed on the bearing seat (12). Bearing block (12) is fixed on the diesel engine block (14) by bolt (13). The other end (9) of the connecting shaft (1) is a spline structure, which is matched with the spline hole of the input flange (10) of the elastic coupling (6). The bolt (7) fixes the shaft cover (8) on the spline end (9) of the connecting shaft (1), and closes the spline groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com