Test determination method for friction coefficient of contact surface of bearing cap and bearing pedestal

A friction coefficient, bearing cap technology, applied in electrical digital data processing, special data processing applications, instruments, etc., to achieve the effect of shortening the research and development cycle

Active Publication Date: 2016-12-07

CSSC POWER INST CO LTD +1

View PDF5 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, there is no report on the determination method of the friction coefficient of the contact surface between the main bearing cap and the bearing seat in the marine diesel engine structure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

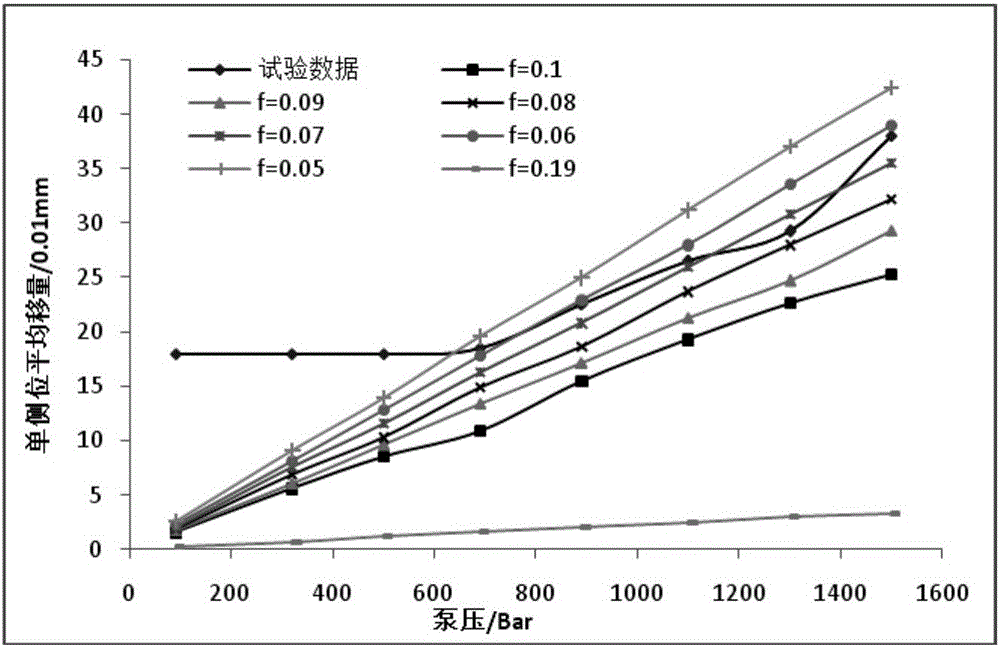

[0026] The friction coefficient of the contact surface between the main bearing cover and the bearing seat of a marine low-speed diesel engine is determined by the method of combining experiment and finite element technology.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

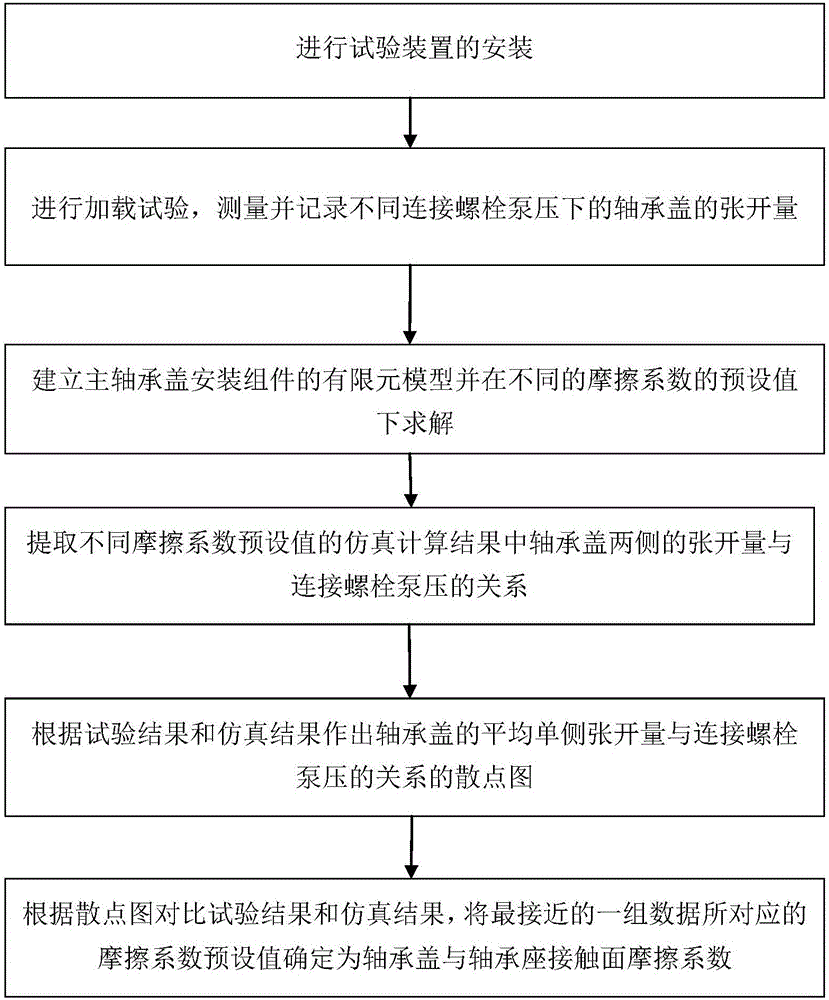

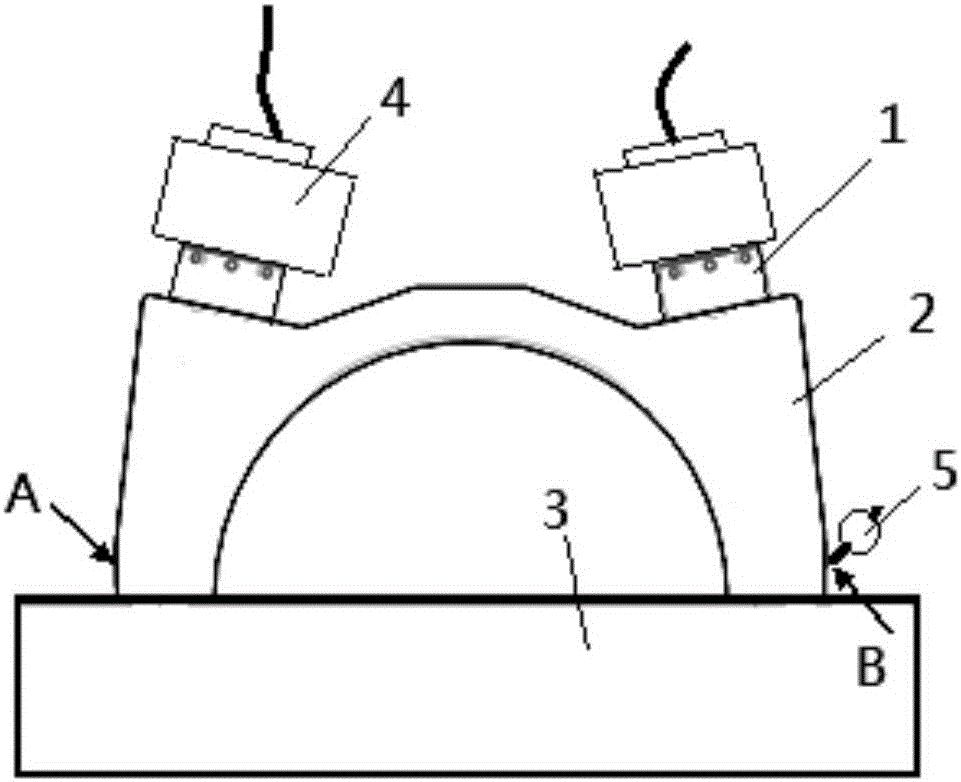

The invention discloses a test determination method for a friction coefficient of a contact surface of a bearing cap and a bearing pedestal. First a test device comprising connection bolts, the bearing cap and the bearing pedestal is mounted; the connection bolts are loaded for a test; loaded bolt pump pressure and related data of the opening amount of two sides of the bearing cap corresponding to the bolt pump pressure are measured and recorded; corresponding relationships between the bolt pump pressure and the expanding volume in a test result are obtained; analogue simulation calculation under different friction coefficient preset values is carried out on the loading processes of the connection bolts by employing a finite element method, and the corresponding relationships between the bolt pump pressure and the corresponding the opening amount of two sides of the bearing pedestal under the friction coefficient preset values in a simulation result are obtained; a scatter diagram for the relationships of the opening amount of two sides of the bearing cap and the bolt pump pressure is made according to the test result and the simulation result; and the simulation result and the test result are compared, and the friction coefficient of the contact surface of the bearing cap and the bearing pedestal is determined according to the closest data. According to the method, the friction coefficient of the contact surface of the bearing cap and the bearing pedestal that better satisfying a practical structure can be obtained; a more precise boundary condition is provided for strength check of the complete machine, and the research and development cycle is shortened.

Description

technical field [0001] The invention relates to the structure of a marine diesel engine, in particular to an experimental method for determining the friction coefficient of a contact surface between a bearing cap and a bearing seat, and belongs to the technical field of marine engines. Background technique [0002] After the structural design of the marine engine is completed, the strength of the whole machine needs to be checked. At present, the finite element technology is mostly used to analyze the structural strength and fatigue life of the whole machine, and it is necessary to define mutual constraints on the divided finite element mesh model of each component. Relationships, including nonlinear contact, coupled and bound constraints, and more. For the nonlinear contact surface, it is necessary to define the corresponding contact properties, including parameters such as the friction coefficient of the contact surface. After the mutual constraint relationship between th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06F17/50

CPCG06F30/15G06F30/23Y02T90/00

Inventor 王奎张琼宇屠丹红刘旭王子威

Owner CSSC POWER INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com