Goods shelf structure of vending machine

A vending machine and shelf technology, applied in the field of vending machine shelf structure, can solve the problems of reducing machine inventory or loading space, waste, etc., and achieve the effects of low production cost, simple installation, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

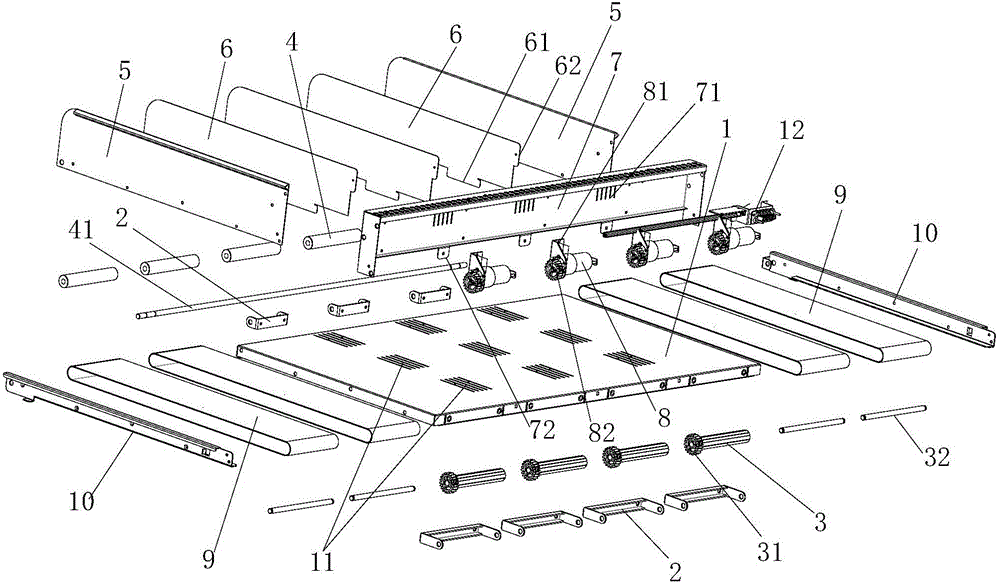

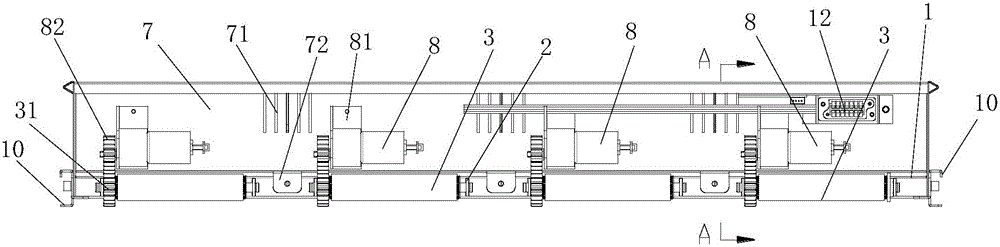

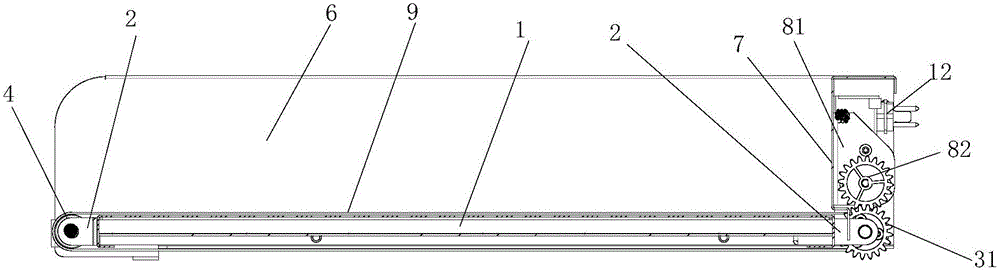

[0021] Embodiment 1: refer to Figure 1-6 . A vending machine shelf structure, the shelf board 1, a number of delivery warehouses, the shelf board 1 is arranged horizontally with a number of delivery warehouses, each delivery warehouse includes a motor 8, a driving roller 3, a driven roller 4 and a conveyor belt 9, The driving roller 3 and the driven roller 4 are respectively connected to the rear end and the front end of the shelf board 1 through the bracket 2, and the conveyor belt 9 is respectively sleeved on the outside of the shelf board 1 between the driving roller 3 and the driven roller 4, and each motor 8 is respectively The drive is connected to each driving roller 3. A partition 6 is arranged between two adjacent conveying warehouses, and an outer partition 5 is arranged on the outside of the conveying warehouse on the outer side on both sides, and a rear baffle is connected above the shelf plate 1 near the side of the driving roller 3 7. Each motor 8 is respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com