Contact box and switching device

A switchgear and contact box technology, applied in the field of contact boxes, can solve problems such as uneven thickness of sealing insulators, product cracking, etc., and achieve the effects of compact structure, good environmental protection of materials, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

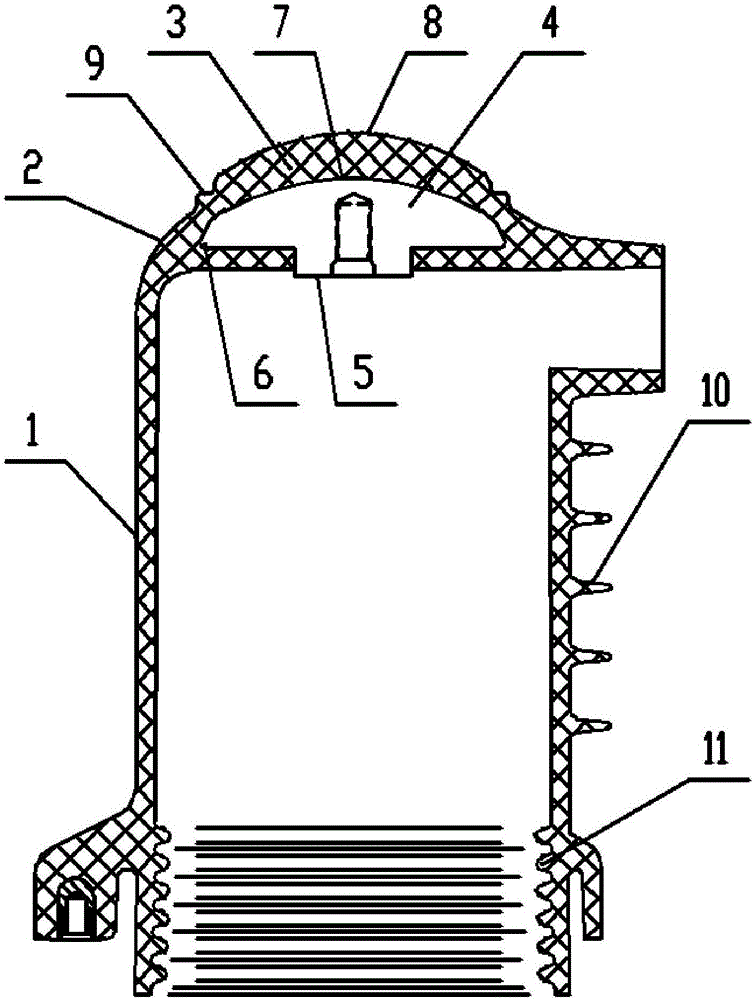

[0027] Embodiments of the contact box of the present invention, such as figure 1 As shown, it includes a cylindrical insulator 1 and a sealing insulator 3 connected to one end of the cylindrical insulator 1 through a transition shoulder 2, and the sealing insulator 3 is provided with a static contact installation insert 4; the static contact installation insert 4 is The umbrella handle 5 faces the mushroom-shaped structure of the cylindrical insulator 1, the outer edge 6 of the fixed contact installation insert extends to the transition shoulder 2, and the surface 7 of the side facing away from the cylindrical insulator 1 has a spherical structure.

[0028] The surface 8 of the sealing insulator 3 facing away from the cylindrical insulator 1 has a spherical structure, and the spherical structure of the sealing insulator is arranged concentrically with the spherical structure of the static contact mounting insert. The transition shoulder 2 has an annularly arranged stepped tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com