Full-automatic rice seedling throwing device

A fully automatic rice paddy technology, applied in planting methods, applications, agriculture, etc., can solve the problems of no seedlings, more than one seedling in some places, easy damage to the roots of seedlings, and heavy workload of farmers. The effect of fewer people operating and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

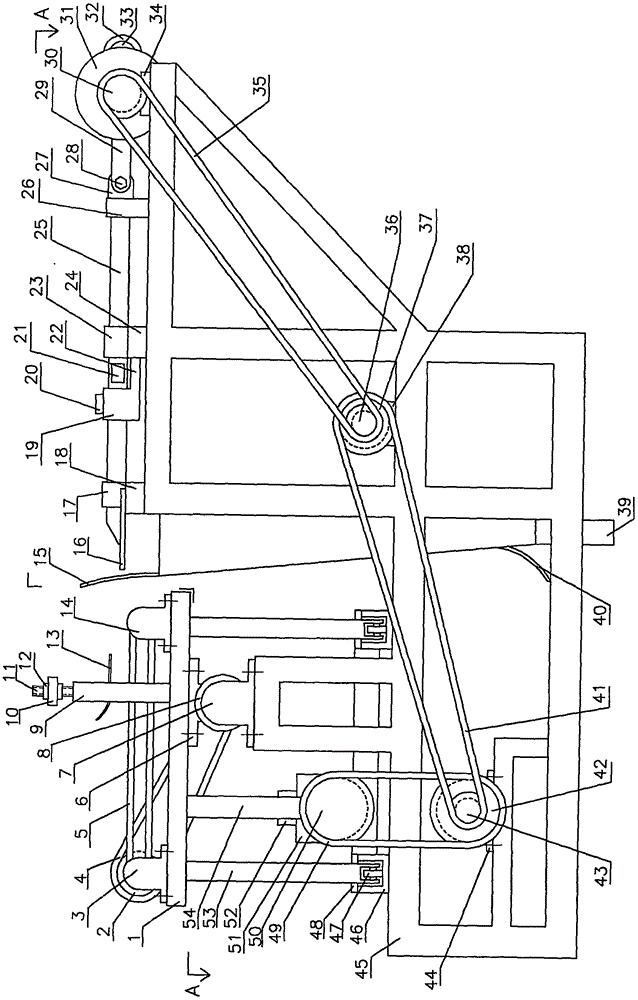

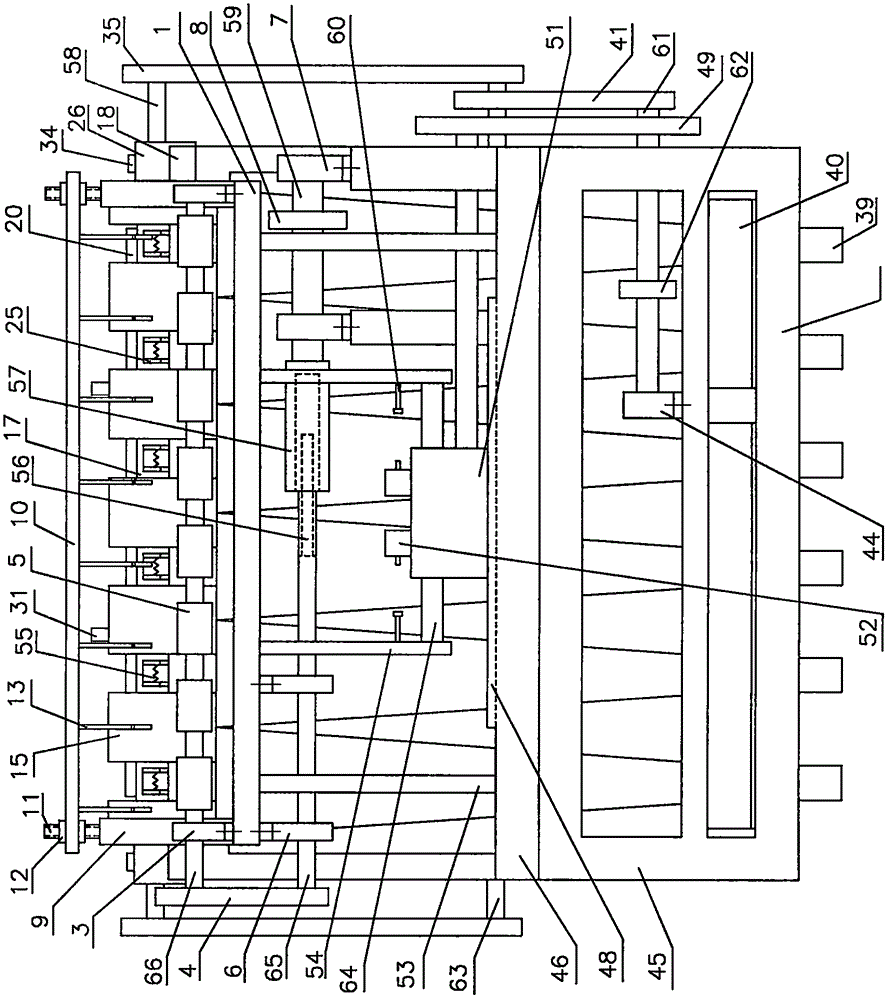

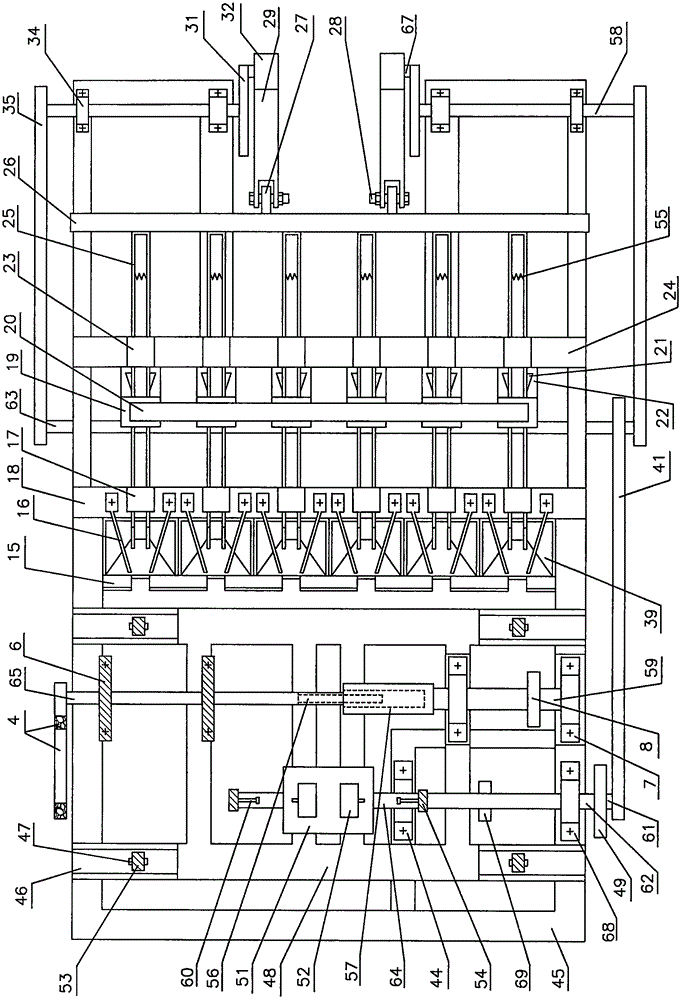

[0037] exist figure 1 , figure 2 , image 3 In the shown embodiment, one group of seedling bucket 39 is welded on the middle part of support 45, and two U-shaped grooves 46 are arranged on the support 45, and the middle part of every U-shaped groove 46 has U-shaped groove cover plate 48, described The U-shaped groove cover plate 48 is used to limit the movement range of the support foot 53 in the U-shaped groove 46 . The conveying plate 1 is supported by four legs 53 , the lower end of each leg 53 is connected with a wheel 47 , and the lower end of the legs 53 and the wheel 47 are placed in the U-shaped groove 46 .

[0038]Shuttle 51, two travel switches 52 are installed on this seedling throwing device, and one end of shuttle rotating shaft 62 stretches in the shuttle, and the other end of shuttle rotating shaft 62 is connected with the bearing sleeve in the shuttle shaft bearing block 68, reciprocating Device driving gear 50 is installed on the reciprocating device rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com